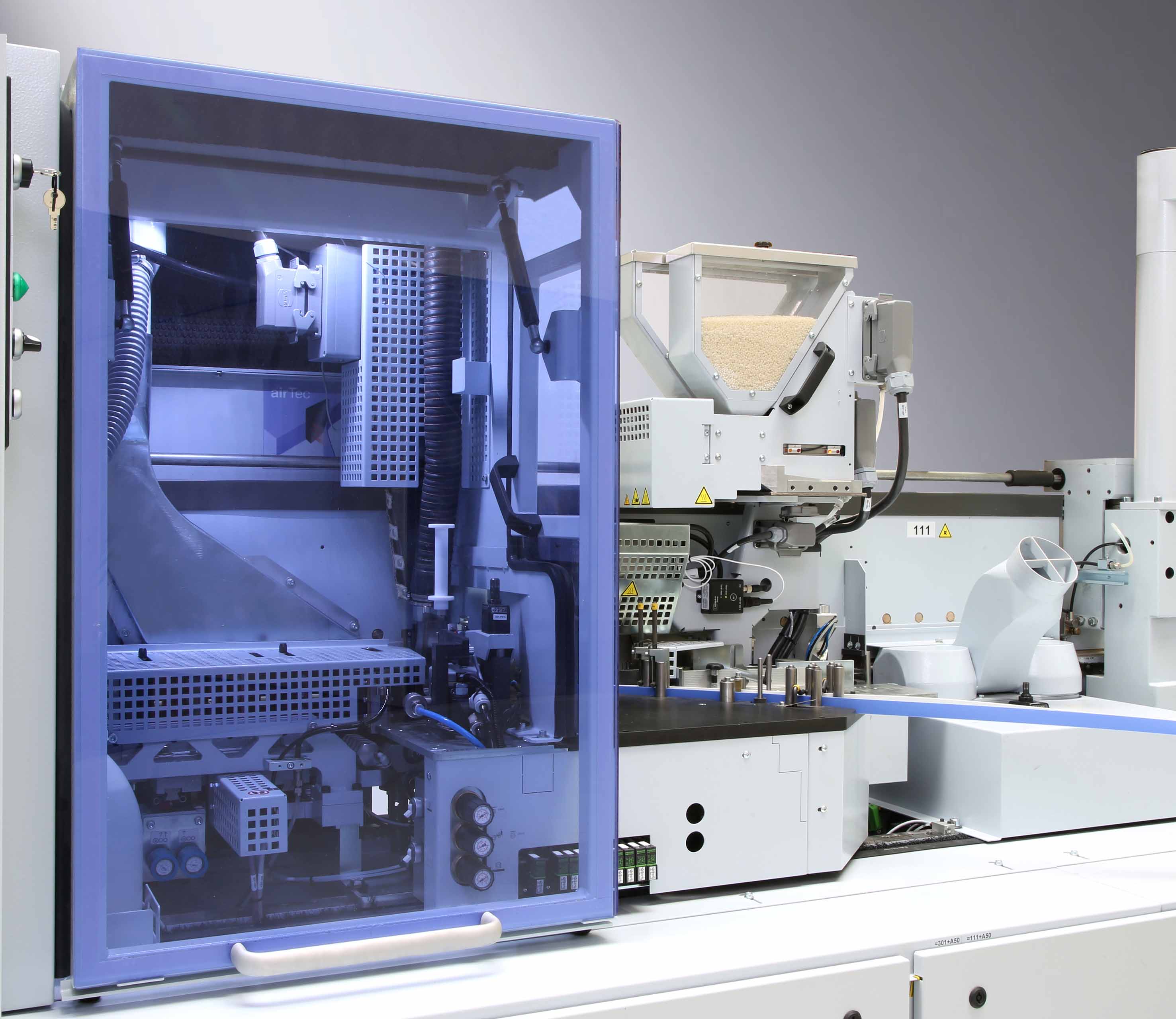

The airTec process has become an established zero joint solution in woodworking shops and SMEs. The HOMAG Group was presenting a new entry-level solution into zero joint technology in autumn. This is significantly more efficient and available for machines with feed rates from 8 to 25 m/min. The process can be used from the entry-level machines of the Ambition 1200 series to the highly sophisticated machines of the KAL 370 series. Reduced noise: The noise emissions during the activation process have been significantly reduced, and are now below the noise level of the other processing units. In stand-by, the exhaust air volume has been reduced almost to zero – meaning the airTec is only audible during edge banding. More efficient and resource saving than before: This is made possible by a new energy source principle. At its heart is a rotation air heater (patent registered) which heats the air and simultaneously stores the warmth for subsequent repeated air heating.