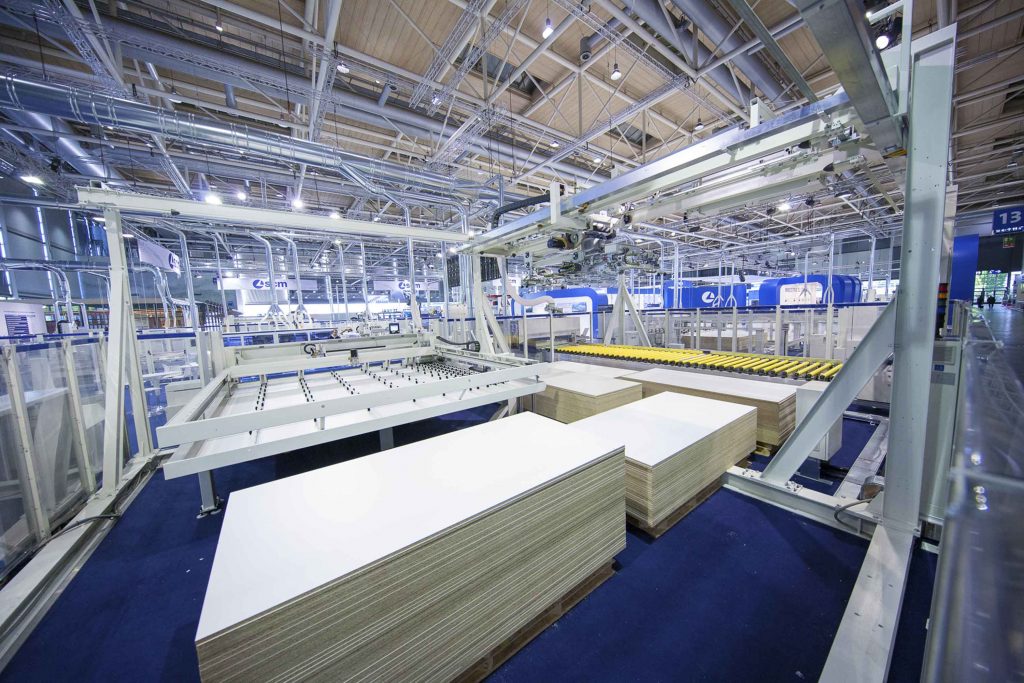

Thousands of customers and business visitors flocked to the splendid SCM booth, where over sixty technological solutions were presented, including the “Cell Lean 4.0” for highly automated industrial production. Compared to the 2015 edition of the fair, the number of orders, agreements and contacts increased considerably. This confirms the sharp growth in the sector, which after the positive signs registered in 2015, is now enjoying a period of full-blown expansion.

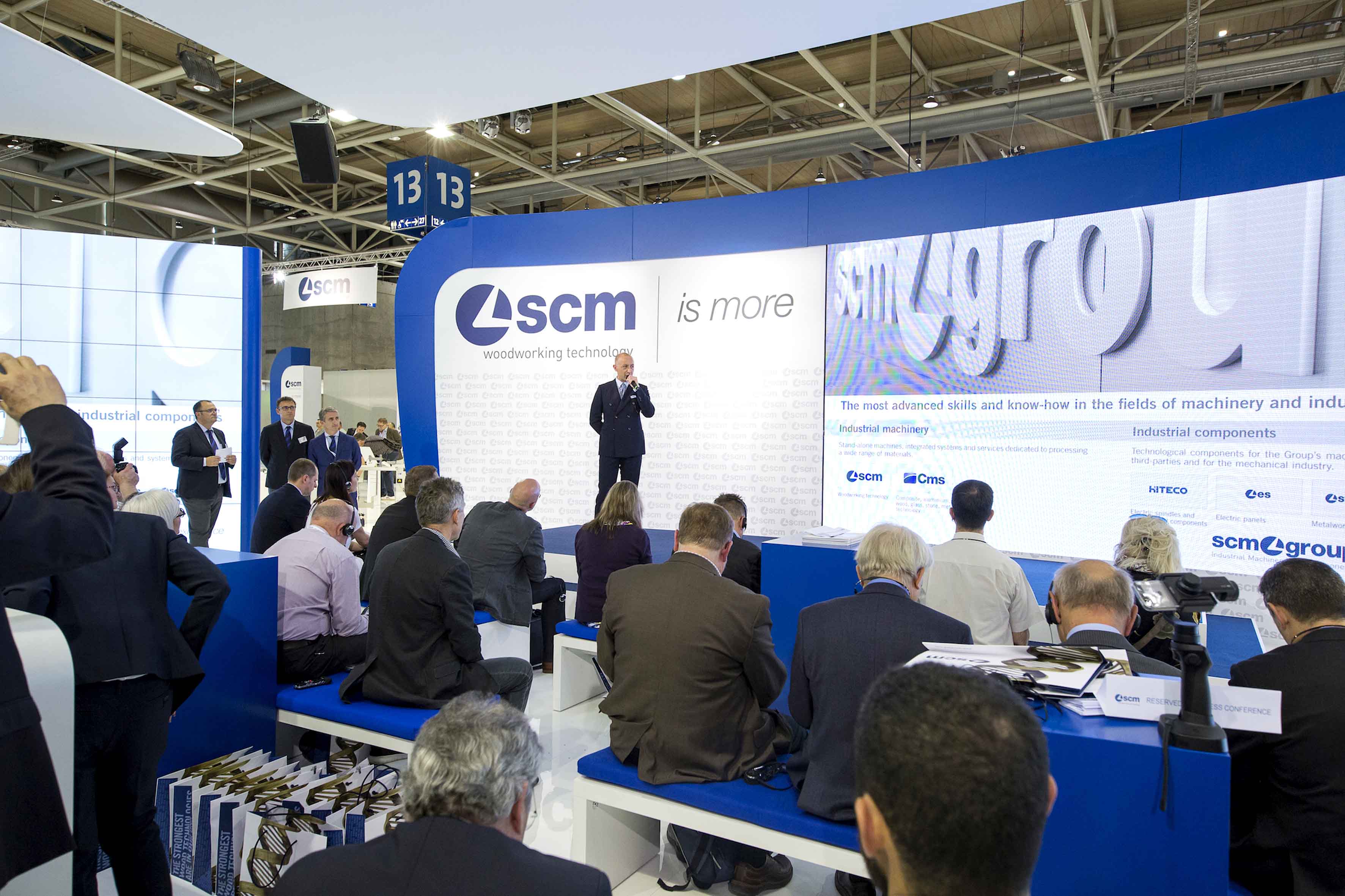

SCM had the pleasure of being represented at the closing press conference by Luigi De Vito, Director of the SCM Woodworking Machinery Division and vice president of Eumabois. This was a prestigious honour for SCM that has been a worldwide leader in this sector since the 1960s.

In his address, De Vito emphasized the increasing internationalization of the event. In fact, Scm was contacted by customers from over 60 different countries from all around the globe and succeeded in creating new relationships with a number of up and coming countries.

Luigi De Vito’s speech underlined the importance of Industry 4.0 technological solutions for the future growth of the entire sector, “Companies, today, are ready for Industry 4.0. The wide use of robotics should not be confined to a simplistic and incorrect equation of saving labour costs, but should be focused on creating and forming a more highly qualified workforce. In our sector, human labour will never lose its central role. The use of advanced technology allows our companies to appeal increasingly to highly qualified young people who represent the future and already feel completely at home with these new techniques.” The German market displayed its considerable strength and SCM registered a 35% increase in German visitors attracted by “Made in Italy” technology. In its refined, white and blue booth, SCM presented a range of woodworking technology so vast no other booth at Ligna 2017 could compare with it. This range stretched from classical machines to automated systems for industrial-scale production.

A particular favourite was “Cell Lean 4.0”, an integrated solution for flexible production that applies “Industry 4.0” and “mass customization” concepts in a way that is concrete and feasible. The solution presented is completely automated, controlled by Maestro Watch software and served by an anthropomorphic robot fitted with a piece recognition viewer. The cell uses standard, absolutely reliable, high performing, easy to use and configure machines. The system operates automatically from the moment the order is launched and can be used with any operating system. The cell is therefore able to manage automatically and with only one operator, all machining phases, from standard panels to furniture assembly.

Cell Lean 4.0 demonstrates the skills of the SCM engineering division, whose aim is to present simple, functional solutions that allow work flows and times to be calculated precisely, and a quick and certain return on investment to be guaranteed.

The SCM booth was one of the busiest in the entire event. Its main focus was a large square, the SCM Arena, that featured a tribute to the heroes of Ground Zero, in the shape of a 12 metre long table made by Riva1920 from thousand-year-old kauri. The concept of the square was used symbolically to represent the way people have met to talk and exchange goods throughout history.

In the same way, people came together in the SCM Arena to share their knowhow, experience and the latest trends in woodworking technology. For four days, SCM specialists, together with customers and guest speakers took part in a packed programme of daily events.

Ligna closed its doors with almost 100 thousand visitors and 2.8 million contacts on its various communication platforms.