Integration, interconnection, automation and digitisation: with these key words, Biesse brings its innovative technical solutions for machining advanced materials to CIFM/Interzum, to shape the Factory of the Future.

CIFM/Interzum is the international trade fair that set to take place in Guangzhou from 28 to 31 March, dedicated to the woodworking machinery, furniture production and interior décor trade fair.

With 150,000 square metres of space, more than 1,509 exhibitors and over 90,000 visitors, Interzum represents a meeting point between production technologies and industrial supply chains.

Biesse offers a full range of technologies that can meet all market demands and handle all machining processes: cnc processing, sizing, sanding, edgebanding and drilling.

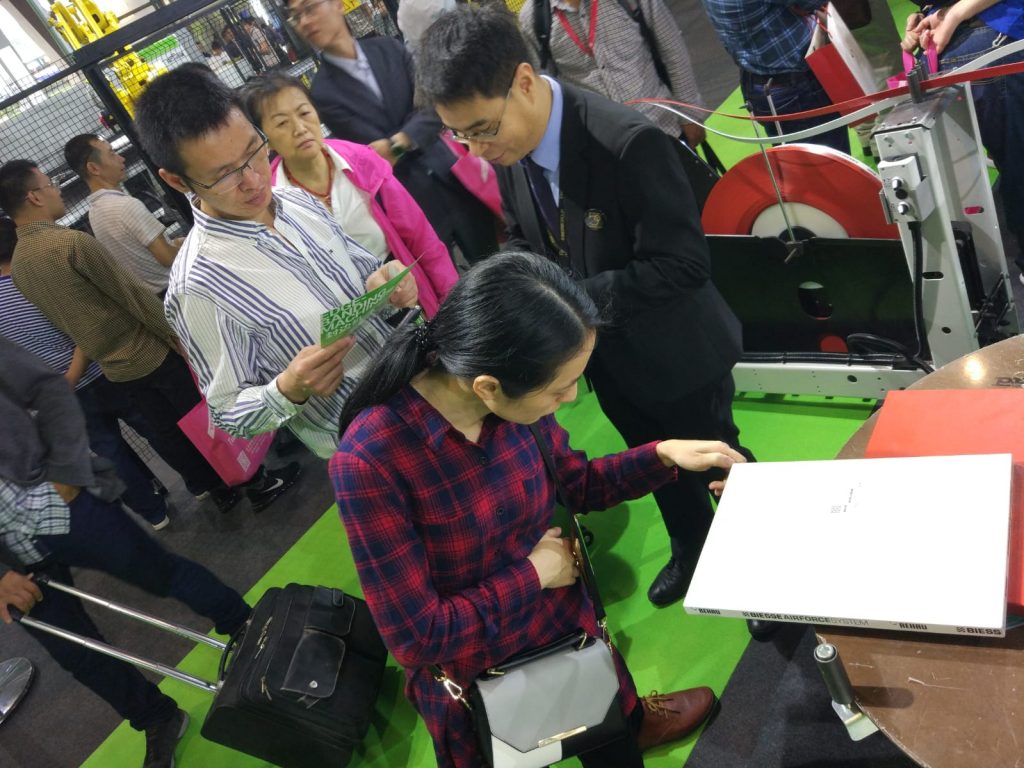

At Hall 11.1, Stand D31 visitors will be able to learn about the entire range of machines for woodworking: in order to meet Chinese custom furniture market demands, Biesse will present the innovative technologies Stream BK (tandem line) + Conveyor, Stream A e AFS (Air Force System), Stream K, which are specially design for Chinese market demands. Stream K, Stream AK are the new solutions of automated single-sided edgebanding machines aimed at craftspeople and small enterprises who wish to increase their production capacity.

Biesse has developed an all-new technology like non-other of its kind for the application of edgebanding strips to shaped panels: RAY FORCE SYSTEM. Its revolutionary nature is based on an incomparable technique which uses infrared lamps to fuse a reactive layer. The advantages are unmatched: maximum quality of finish, reduced energetic consumption, and ease of use.

The lack of a glue line guarantees the continuity of the panel’s surfaces for an aesthetic result of great and enduring quality.

The RAY FORCE SYSTEM for shaped edgebanding alongside the best-selling AIR FORCE SYSTEM technology for linear edgebanding, also on display, makes it possible to cover all possibilities of the process for this kind of machining operation.

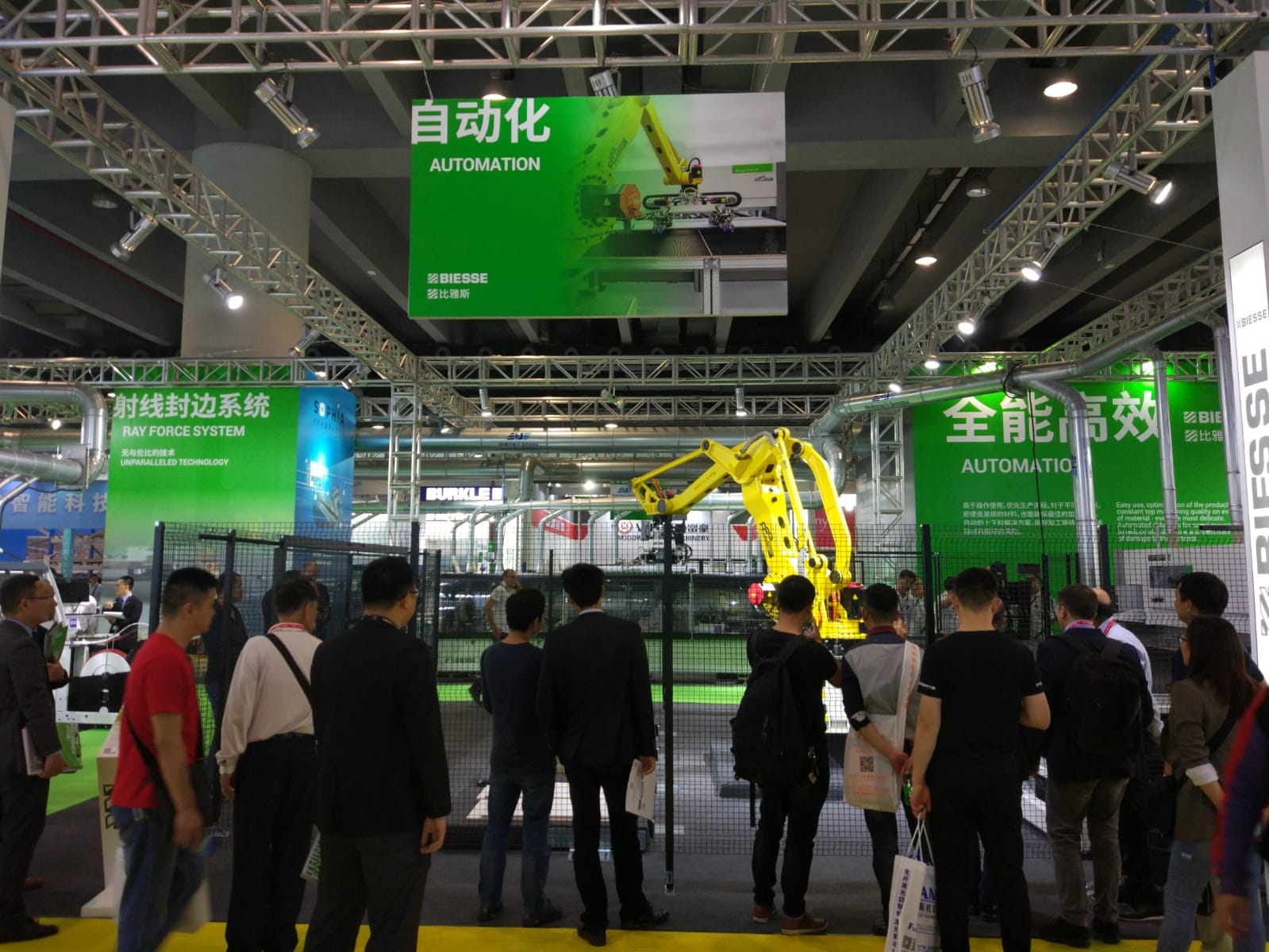

Also, on display at the stand will be the Selco WN 6 ROS (Robotically Operated System), the new technological solution with integrated robot for handling panels to obtain maximum efficiency and versatility without the operator’s intervention.

In order to constantly make the factory more efficient, Biesse pairs robotisation and digitalisation with the development of new software and continues the innovative journey that started with SOPHIA, the IoT service platform, expanding its functionality to embrace predictability, which will greatly improve the customised interaction with the customer when it comes to the machine and will significantly reduce the time required for assistance.

Visitors to INTERZUM will be able to experience the cutting-edge technological innovation that characterises Biesse, test the tools that enable customers to obtain greater value from machines, and see how SOPHIA can revolutionise and simplify everyday work.