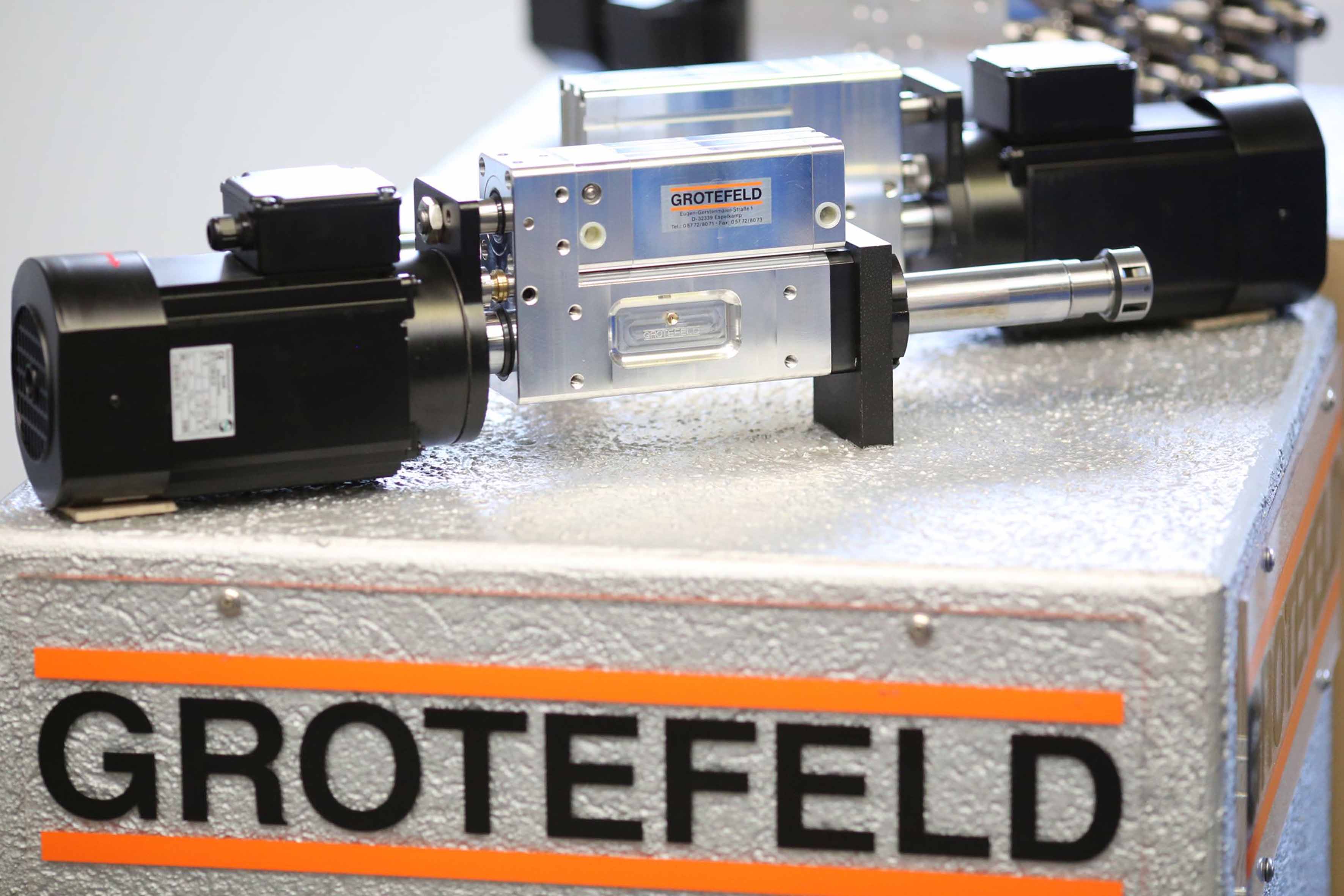

The system supplier Grotefeld GmbH (Espelkamp, Germany) is a highly specialised producer of high-quality power unit technology. The efficient and high-performance components offered by the company are process oriented, whereby the focus lies in the areas of drilling, milling, sawing, cutting, grinding and tracing.

For many years now, the enterprise has been developing new applications in terms of the materials to be processed – ranging from plastics and metal to gypsum and cement right through to composites. These innovative developments will be highlighted in impressive fashion by Grotefeld at its stand D72 in hall 12 at the forthcoming leading trade fair “Ligna 2017”.

The company, which is based in East Westphalia, has fully embraced this year’s motto of the fair “Processing of Plastics and Composites” by gearing its presentation at Ligna towards its own units, which are highly resistant to mechanical stresses, for the processing of interesting and unusual materials. Grotefeld’s extensive product portfolio will enable the company to show multifaceted applications going far beyond the “customary” uses in the timber and furniture industry.

From a standard power unit to specialized applications

The drilling of gypsum-cement panels, for instance, poses a particular challenge. The highly abrasive dust mixed with the moisture in the air causes considerable problems for both the stability of the unit and the guarantee of the long-term operation of the controllable drilling gear, which have been ingeniously solved by the engineering company.

Although the machining of glass and carbon fibre reinforced plastics (GRP and CRP respectively) is entirely different, their processing is by no means less demanding. Grotefeld offers special, smart machining solutions both from a technological point of view and in terms of health-related aspects.

The diversity of the properties of plastics fundamentally necessitates extensive development work in the field of premium power unit technology. Although high torque values are mostly required for the machining of such materials, the frictional heat generated by the tool can cause some plastics to melt. Grotefeld demonstrates how to overcome such problems by means of its gear reductions.

Nowadays, metalworking almost always involves the use of so-called minimum quantity lubrication or lubricant feed through the tool. The top-class supplier also offers its customers attractive power unit developments for such applications.

Innovative power units for all industrial sectors

Composites are a booming segment in industry. The processing of sandwich elements is regarded as “a fine art” since the combinations of materials are virtually infinite and new ideas are presented almost every day. Grotefeld will be the first port of call for companies wishing to hold their own in the processing of this category of materials.

The “hidden champion” from Espelkamp has been developing socalled “non-wood innovations” for some time now. Working hand in hand with its international clients on the development of new systems enables its partners to quickly achieve and maintain a competitive edge. Whether shipbuilding, the caravan industry, producers of insulation materials, the automotive or aviation industry – Grotefeld is regarded as a pioneer and driver for innovation when it comes to smart power unit and machining solutions.