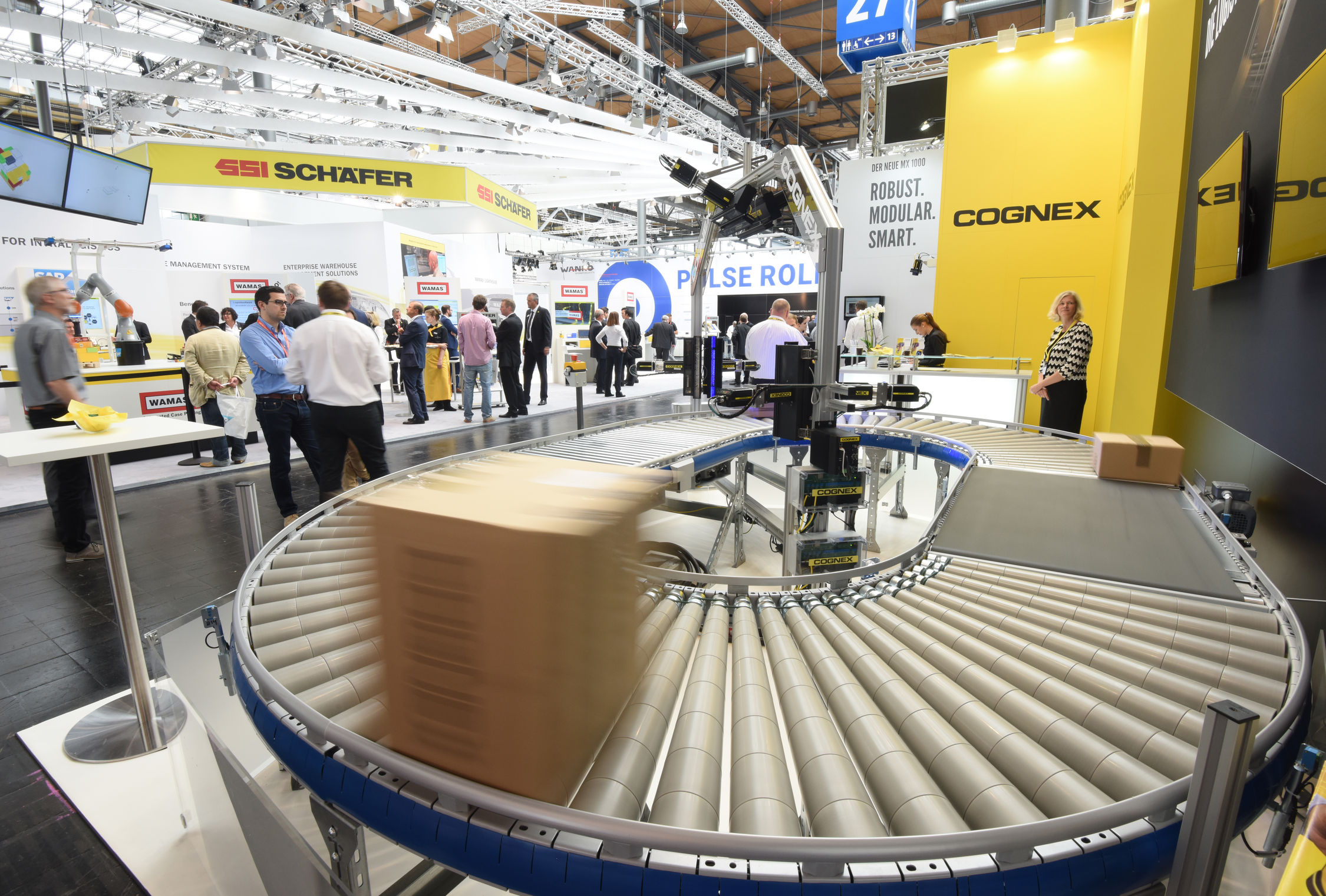

Jointly with partner companies PCO and nemetris, HARTING Technology Group showed at the CeMAT Logistics 4.0 Hub how handling, status and system data can be collected and analysed along the supply chain using a combination of edge computing and the latest RFID technology. The CeMAT Logistics Trade Show is part of HANNOVER MESSE, the world’s leading industrial trade show held from 23 to 27 April 2018 in Hannover.

Logistics with its material handling systems benefits enormously from the new innovative solutions of Integrated Industry. HARTING’s MICA® edge computing system is the perfect partner for these. The robust design, modular hardware kit and open software architecture of the mini-computer impressed the HERMES AWARD 2016 jury and saw the MICA® crowned the winner. Since then HARTING has created a user organisation in the form of the MICA.network, currently consisting of 27 companies working in the system integration, software and hardware development sector, who use the MICA® for complete Industrie 4.0 solutions. The two partner companies PCO and nemetris use MICA® for example as an RFID reader with edge computing capabilities for their own logistics solutions.

AutoID-supported container management and Tool Ident

PCO showcases a practice-oriented production order process, where the key role is played by the PCO integration layer for the integration and interaction of different systems. For example, auto-ID supported container management (mobile handheld) and Tool Ident (stationary in the machine) are networked with each other and displayed with machine, process and production order data. With the addition of database-based process data storage, predictive maintenance can also be introduced.

Just-in-sequence software for flexible and efficient production management

The just-in-sequence JIS solution by nemetris is extremely closely linked to production and maps the whole just-in-sequence process, from acceptance of the call-off via EDI through sequencing and just-in-time production management to shipment and implementation of traceability. The nemetris solution is modular and can be integrated seamlessly into an existing infrastructure. On the one hand this ensures lean and smooth processing and allows series production at batch size 1, on the other all the data remains in one system, which enables unbroken traceability.