AAP-NDT was founded in July 2015, in Eurotec Center Moers – Germany, due to a marked increase in demand for vendor-independent IT solutions for workflow management and digital reporting in non-destructive testing (NDT). Under the management of Achim Hansen, they have so far successfully driven the development and implementation of the software.

In January 2019, the company was able to acquire DÜRR NDT GmbH & Co. KG from Bietigheim-Bissingen as a new strategic partner and shareholder for them to also build up the international business.

Since May 2019 AAP-NDT is located in the middle of the new technology park PHOENIX West in Dortmund. An optimal infrastructure that offers more development potential for AAP-NDT and supports them in the growth.

AAP-NDT’s mission is to optimize testing processes, provide intelligent data processing of test results and support international IT standards. And they are happy to help interested customers and partners with individual project and IT consulting.

Interview with Achim Hansen, Managing Director at AAP-NDT GmbH.

Easy Engineering: Which are the fields of activity where you are operating?

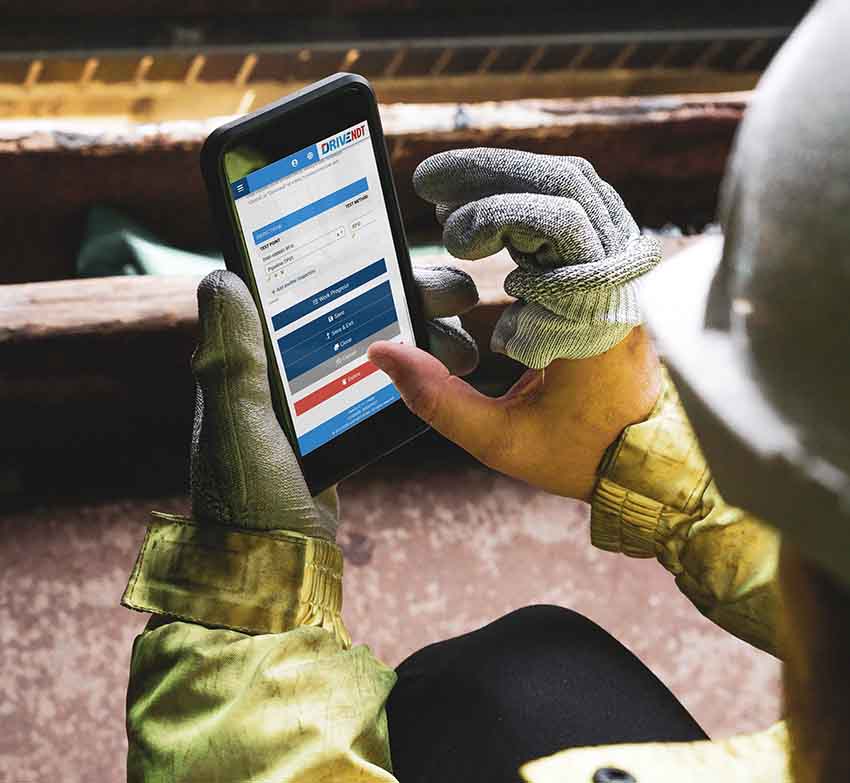

Achim Hansen: We develop software for the NDT market. Our software DRIVE NDT is a cloud-based management software for all NDT test procedures and related processes. With DRIVE NDT, the entire NDT workflow can be organized and controlled, including individual test reports, personnel, customer and equipment management and much more.

E.E: Which are the most significant projects in the history of the company?

A.H: We have already successfully mastered a number of challenges. Both with large and small service providers, manufacturers or also companies in the chemical industry. However, an important, future-oriented project was the integration of the RT-D evaluation software D TECT X from DÜRR NDT into our software DRIVE NDT. This integration enables the automated transfer of measurement results and images into the test report, which represents a significant workload reduction for customers.

E.E: What projects were the most challenging?

A.H: The biggest challenge was to develop a software that covers all aspects of NDT. It was important for us to develop a platform or a NDT operating system that can be used by all customer groups. Flexible and intuitive usability, auditable and that has a data base for AI applications.

E.E: What are the ranges of products and what types of services do you offer?

A.H: We offer our management software DRIVE NDT and a corresponding project consulting in which we are highly specialized. We would like to remain focused on this. In the course of further digitalization, however, we will include the new products of our partner DÜRR NDT in our portfolio. These are AI solutions (automated or supporting evaluation in digital projection radiography) and archive solutions (PACS Picture Archiving and Communication System).

E.E: Which are the most innovative products / services and what special features do they have?

A.H: DRIVE NDT! DRIVE NDT consistently maps the entire workflow of the inspection departments in one system. This enables focused control of all workflows and an optimal status overview of all inspections, orders and reports. The integrated modules include inspection report generation (audit-proof), order management, test object management, inspection personnel management (incl. certificates, medical examinations and more), equipment management, norms and standards, turnover and time logging, etc. Working with different applications and programs is thus a thing of the past.

E.E: What was the research behind the products/solutions and how important is R&D?

A.H: A deep market research with a lot of Voice of Customer is in our products as we were working close with our customer to develop the right solution for our target group. So it fully reflects the needs of our customers. This of course goes along with R&D affords which have been implemented already in our software and permanently are. Even customization on customer’s requests are possible and implemented via our R&D Team on demand.

E.E: What products / solutions are you going to launch in the future?

A.H: We are focused on the digitalization of the NDT industry and will continue to develop DRIVE NDT and integrate DÜRR NDT’s AI and PACS solutions deeper and deeper into our software. We don’t see any other products at the moment – let’s see what else happens in the future.

E.E: How important are the after-sales services?

A.H: A very important point of our corporate philosophy. Fast response times to questions and problems are very important to us. There is nothing worse for customers than when no one responds to problems or special questions or customization. In the meantime, we have gained a very good reputation with our customers, which is always the first thing we hear when they recommend us to others.

E.E: Tell us about social responsibility and what part does it play in the company?

A.H: Our relationship with customers and partners, employees, and our focus on future-oriented and sustainable solutions for the NDT industry is always guided by the principle of social responsibility. We are convinced that social responsibility and integrity are an essential foundation for long-term success. This is why DÜRR NDT also supports the Mercy Ships organization, which provides free surgery and medical care for people in need in Africa through its hospital ships.