AMCS technologies, created in 1994, designs and manufactures high-end electronic devices dedicated to construction sites safety. Specialized in zoning and anti-collision for lifting equipment, the company has become essential in its activity.

AMCS technologies become a reference in France and through the world by the quality and the optimal performance of its flagship product, the DCS 60 released in 2011. The company also offers a new generation of complementary products: ground monitoring systems 3D, windspeed indicators, day and night aviation lights and cameras.

What are the main areas of activity of the company?

Thousands anti-collision systems was installed worldwide today at key sites such as the Santiago International Airport, Hinkley Point C nuclear plant in United Kingdom, Atlantic Bridge in Panama, and the Abu Dhabi Airport, amongst many others.

What’s the news for 2020 about new products? What are the most innovative products marketed?

The DCS 61-S, (Driving Control System Safety), the new anti-collision and zoning system now available for international marketing.

It is a complete safety system designed with a higher level of requirement to ensure the safe execution of orders to manage the machines in interference, operating in the area of the tower cranes.

The device is in the process of being certified PLd in accordance with the standard EN13849-1 and SIL-2 in accordance with the standard EN61508 by an accredited organization, in order to guarantee a serious quality approach.

Operating on many sites in France, the DCS 61-S can detect in real time the risk of collision of all crane elements in interference (for example cable on jib, cable on counter-jib…) or the risk of enter a prohibited area (schools, railways, roads, etc.).

It intervenes on the controlled mechanisms of the machine to ensure a slowdown and / or a complete immobilization of the lifting machine at a pre-set distance from the obstacle. The system provides the crane operator with working comfort by displaying all the parameters useful for operating the machine and allows him to program delivery zones and targets more intuitively. It also gives the possibility of viewing in real time the position of the crane in its environment as well as the positions of the interfering cranes while guaranteeing high performance on site productivity.

The DCS 61-S has been designed to integrate new functionalities as they arise. Indeed, it is an evolving system which now integrates the management of anti-collision between tower cranes and mobile cranes.

The IoT Lifting with its mobile application which will be available during the second quarter of 2020.

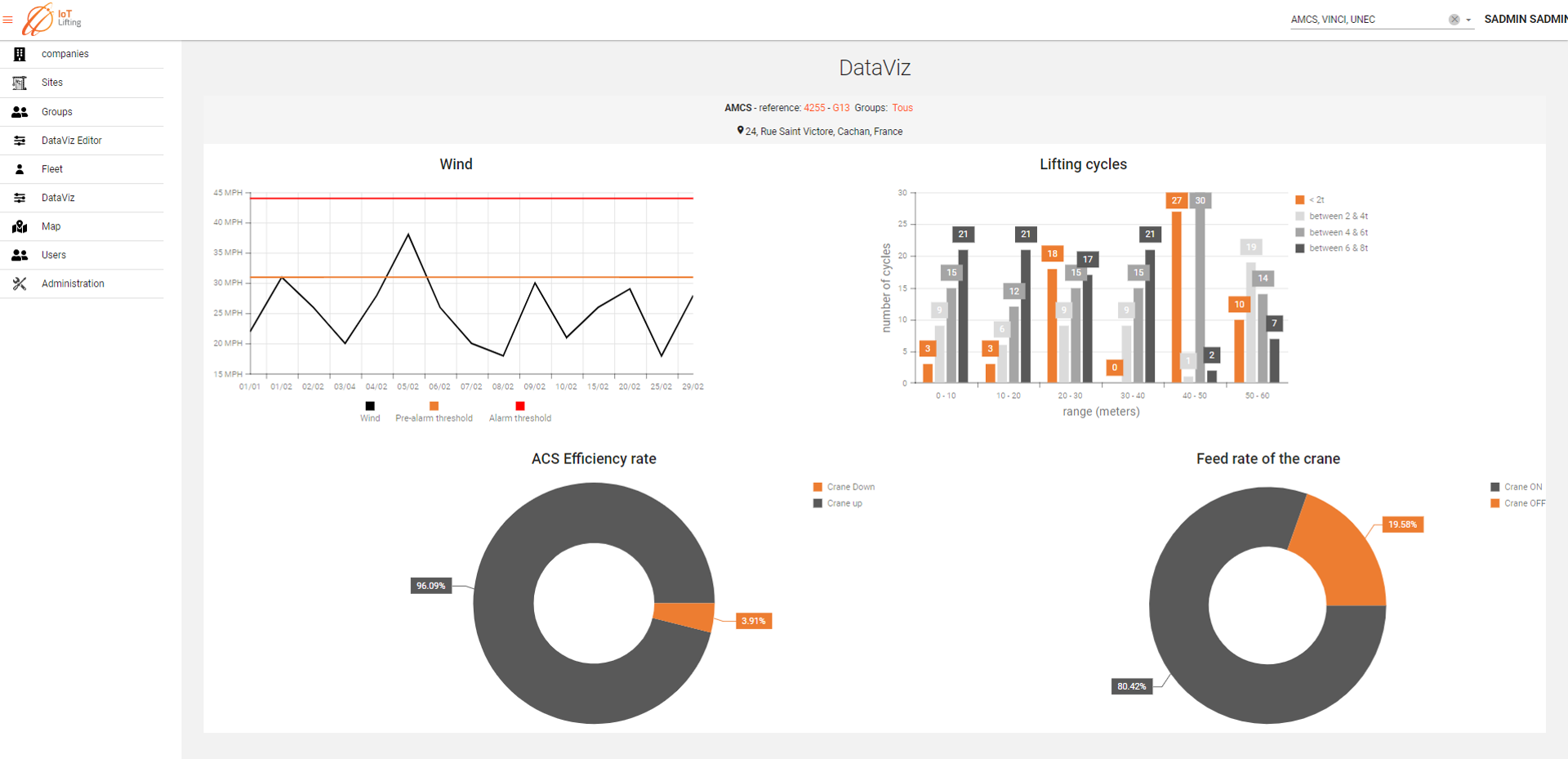

The DCS 61-S anti-collision systems can be equipped with a SIM card that can be used to collect precise data on each crane on a web portal. Thanks to personalized identifiers and access, the website IoT Lifting allows to :

– Geolocate each devices (anti collision systems and job site supervisors)

– Access remotely the display of the connected DCS 61-S screens as well as the SUP61, as if we were in the crane cab or in the site offices

– View and download information on system events (when the crane is powered, in motion, in weathervane, etc.) and generate personalized statistics for each job site and companies (occupancy rate, load, efficiency, interference …).

The main objectives of the IoT Lifting are to follow the productivity of the construction site with precision and remotely and to know the activity of the cranes every day.

The IoT Lifting mobile application (available internationally on Android and Apple Store) will guarantee the productivity and safety of cranes equipped with anti-collision systems DCS 61-S. Each client can:

– Monitor in real time the states (weathervane, neutralization, fault, wind speed, cuts …) of its DCS 61-S anti-collision systems on each of its sites.

– Receive notifications on the status of its DCS 61-S systems.

– Neutralize the function (s) (anti-collision, prohibited areas) in complete safety.

A job site supervisor with BIM option, the SUP BIM, that will be marketed early 2020 in France and abroad.

This supervision tool makes it possible to follow the progress and production of the site in real time. This is recreated virtually by integrating the real types, brands and models of cranes on the site plan and in its real environment (buildings, road, location, etc.) taking into account the digital models of buildings under construction in BIM format.

For a better understanding of the project throughout its life cycle, it allows you to visualize the evolution of the site and its facilities as it progresses. It also provides statistics on the data collected by the DCS 60 or DCS 61-S anti-collision system installed on the crane (rate of use of the crane under load, empty, interference rate, etc.).

A data logger function makes it possible to consult the history of the data for each machine and to download them to a USB key (slewing, height of the hook, position of the machine on the translation railway, etc.). The user can also view and record the wind speed data for each crane equipped with an AMCS technologies anemometer sensor.

An additional function allows the management of overflight limitations selectively by neutralizing directly on the screen one or more prohibited overfly areas. The supervisor can be consulted from one or more computers, tablets or smartphones with a simple internet connection.

What can you tell us about market trends?

The trend is towards the digital transition in order to offer comfort options to customers. The market tends to offer digital tools combining several functions in a single product. Today, the search for product safety and reliability in order to guarantee site productivity is a major focus for companies.

What estimations do you have for 2020?

The focus this year is on new technologies and therefore the safety and performance of the company’s new products and tools. Our anti-collision systems equipped cranes throughout the world, but we would like to develop the East Europe market in 2020, for that, we have hired a new sales manager and developed new partnerships.