In a world where economic and environmental challenges loom large, the heat treatment industry finds itself at a crossroads. It’s a realm where processes need optimizing, energy consumption demands trimming, and product quality insists on reaching new heights. Amidst this dynamic landscape, QMULUS, Nitrex’s Industrial Internet of Things (IIoT) platform, emerges as the hero of the tale, wielding a holistic approach to data integration, normalization, and accessibility. So, let’s embark on a journey to understand the challenges faced by the heat treatment industry, the profound impact of digital transformation, and how QMULUS is set to reshape the narrative.

CHALLENGES: THE INDUSTRY’S BATTLEFRONT

- 1. Economic and Environmental Squeeze:

Imagine a scenario where natural gas prices continue their relentless climb, and environmental regulations keep getting tougher. This is the world the heat treatment industry operates in. The demand for reduced carbon footprints means every subcomponent must come with a certificate vouching for its environmental friendliness. However, achieving this requires a complete digital makeover, which means the industry must transition to a state where it thrives on transparent, detailed information. This shift towards transparency and digitalization is vital for the industry to remain competitive and environmentally responsible.

- 2. Passing the Torch – Aging Expertise:

In the heat treatment world, the seasoned experts are getting, well, seasoned, and the transfer of their invaluable knowledge is becoming increasingly challenging. As these experts prepare to step into retirement, they carry with them a wealth of expertise, often referred to as the “secret sauce” of the trade. The younger generation is enthusiastic and eager to learn, but the fast-paced, cost-conscious nature of the industry doesn’t always allow for a gradual transfer of that knowledge. This struggle has a far-reaching impact on equipment, processes, and, ultimately, product quality.

- 3. Outdated IT Infrastructure:

Picture this: robust heat treatment equipment that stands the test of time, but the systems responsible for running them are stuck in a bygone era. Data silos, outdated software, and a lack of data interfaces have collectively created a digital mess. Within this chaotic landscape, valuable insights accumulated over the years lie dormant, buried in inaccessible data graves. The heat treatment industry is now confronted with a pressing need for a digital spring cleaning, a long-overdue overhaul to unlock the untapped potential hidden within its historical data and modernize its digital infrastructure.

- 4. Stringent IT and Data Security Demands:

In a world where the internet is everywhere, lurking behind every virtual corner are potential cyber threats that demand constant vigilance. The need to protect sensitive data is more crucial than ever. Regulatory frameworks like CMMC (Cybersecurity Maturity Model Certification) set the stage for stringent cybersecurity measures. The heat treatment industry finds itself not only on the path to digitization but also under the mandate to do so securely, ensuring that personal data, proprietary company secrets, and technical information are effectively protected and remain under digital lock and key.

SOLUTION: QMULUS PIONEERS HEAT TREATMENT INDUSTRY’S TRANSFORMATION

In the competitive heat treatment industry, QMULUS, Nitrex’s cutting-edge IIoT platform, emerges as a transformative force. It offers a comprehensive solution to industry challenges, effectively turning problems like escalating energy costs and regulatory complexities into opportunities for operational excellence. More than just a tool, QMULUS serves as a strategic ally, reshaping challenges into pathways for business success.

QMULUS excels in seamlessly integrating diverse data sources, prioritizing metainformation, and implementing normalization processes. The result is a comprehensive data warehouse that provides actionable insights, enhancing the precision of operational decision-making. By tackling the challenges posed by outdated IT infrastructures and data security, QMULUS ensures the fortification of your business against the demands of the digital era.

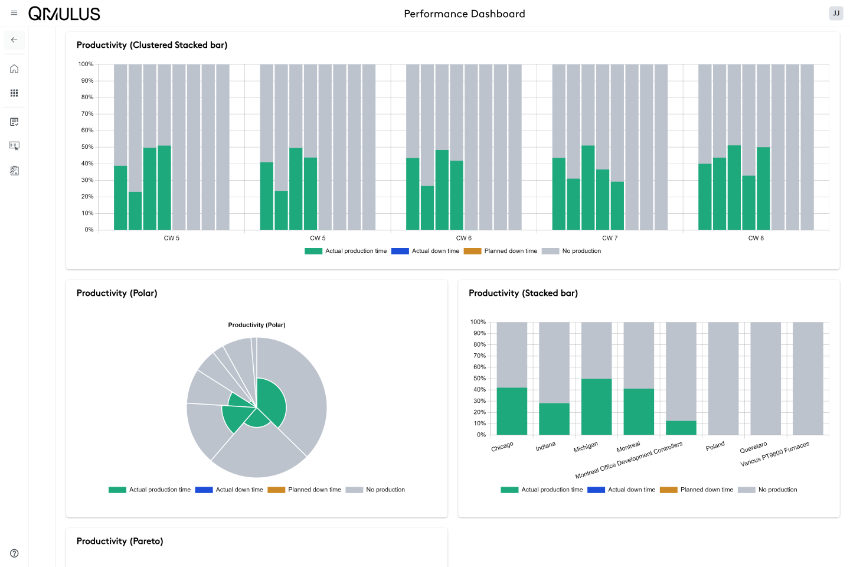

QMULUS unfolds its transformative impact through three interconnected portals: Manufacturer, Customer, and Operator. These portals are not standalone features but strategic elements in orchestrating your business’s digital transformation. The Manufacturer Portal provides real-time insights for predictive maintenance, the Customer Portal ensures transparent traceability of product information, and the Operator Portal empowers real-time monitoring and analysis, optimizing every aspect of your business. The intelligent backbone of these operations lies in QMULUS’ assistance systems, comprising anomaly detection, model processes, and validation tools.

QMULUS is not just a tool; it’s a dynamic force shaping the future of the heat treatment industry. The intelligent assistance systems empower your team to navigate complexities and optimize efficiency. Choosing QMULUS is a strategic investment, evolving with your business and positioning it as a trailblazer in the evolving industry landscape. With QMULUS, your business thrives as a dynamic partner, leading the way in the digital transformation of heat treatment.

Discover the path to profitable and sustainable heat treatment today!