ENDEGS is the expert for mobile and ecological VOC & HAP combustion in Europe. The company offers technologically unique solutions for the time-and cost-efficient combustion of gases, gas mixtures and vapors in explosion groups IIA, IIB and IIC.

Interview with Kai Sievers, CEO ENDEGS Group.

Easy Engineering: What do your customers look after when buying products or services?

Kai Sievers: Our customers look in particular to our many years of experience in the field of mobile degassing. It is important to us and our customers that we address their problems in detail and do not sell them an off-the-shelf solution. In the over 1400 projects we’ve done, we’ve gained a wealth of experience and learned many things. We understand the processes of our customers’ industries, and we know what they need. Transparency is also an important aspect. In each phase of our service, we lay all the facts on the table as a matter of principle. Because facts and figures are the basis of a good relationship.

E.E: What are the main needs of the customers?

K.S: Our customers need solutions for avoiding emissions while maintenance activities. It is important that the services have minimal impact on the customers’ day-to-day business. Our processes are designed in such a way that production can continue and downtimes are minimal. We accompany our customers through the entire degassing process.

E.E: How important are the after-sales services?

K.S: After-sales services are part of our everyday work. It contributes to a good understanding of our customers and helps to make even better offers in the future.

E.E: What after-sales services do you offer?

K.S: When stationary emissions reduction systems fail, too often vapors are simply vented into the air until the system has been repaired. They release large amounts of toxic materials – tons each day – into the environment, poisoning the air for people and nature. Therefore, in addition to our degassing services, we also offer replacements services. For example, we replace VRU, flares and VPS (Vapor Processing Systems). In this way we prevent the operation from being stopped or that the operation is carried out in an environmentally harmful way.

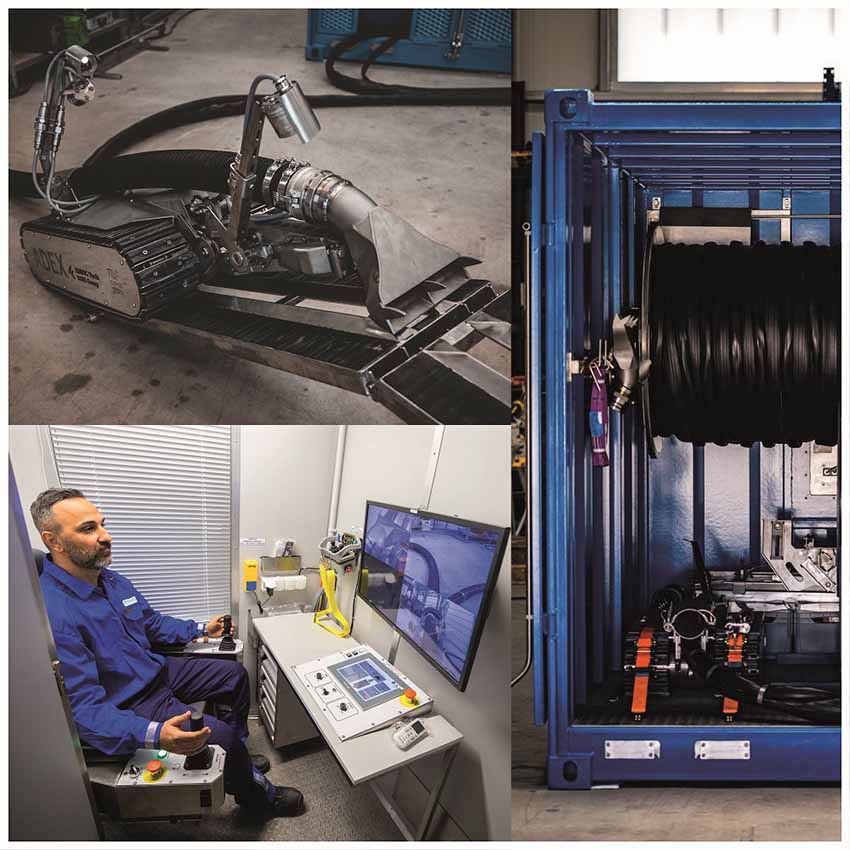

We offer an all-in service package including personnel and additional equipment, as well as individual elements of it, for rent – like a remote-controlled zone 0 robot or mobile N2 vaporizer with nitrogen tank.

E.E: What kind of support do you offer your customers?

K.S: We are always available to advise our customers should they have any questions about the technology or processes. In addition, we offer training for staff – especially when they use our rental services. Well-trained personnel is one of the key requirements for safe, robot-assisted cleaning and efficient processes.

E.E: How do you promote your after-sales services?

K.S: Due to our good relationship and reliability, customers contact us day and night, during public holidays when stationary emissions reduction fail. Depending on distance, we can be in place within hours. We are completely autonomous and can start processing VOC or HAP emissions as soon as the work authorizations are signed.

Tell us about the spare parts distribution (if any) or any other after-sale products.

In addition to our mobile degassing services, we offer our customers various products for rent. We intend to further expand this business in the coming years.

Thus, last year we’ve added another pioneering technology to our line-up: Powerful Zone Zero remote-controlled robots,for the cleaning of above-ground and underground industrial tanks. Customers can rent them to replace people where health risks are acute. ENDEGS provides robots to customers exactly when and for how long they need them, maintained and fully functional. Naturally we take care of getting them to and from the site, wherever it is.

Kai Sievers, CEO ENDEGS

E.E: What impact has product innovation on your customers?

K.S: Especially in our industry, we always have to adapt to the current requirements of the industries, the environment and also legal regulations. That’s why our customers appreciate the fact that we never stand still, but constantly develop ourselves and our technologies. Even our earliest mobile incinerators burned pollutants almost 100 percent – a quantum technological leap. To this day, with each new generation of mobile incinerators, we try to bring innovations to market, that give our customers decisive added value.

This fundamental innovation concept of ENDEGS has now been awarded the TOP 100 innovator seal for the second year in a row. This award confirms to our customers what we embody.

E.E: What industries do you think will grow in 2022?

K.S: As climate change progresses, improving air quality is becoming an increasing priority. By 2050, Europe is to become climate-neutral – in other words, no more greenhouse gases (GHG) are to be released into the atmosphere that are not otherwise compensated. That doesn’t matter only for the switch from diesel and petrol engines to electric vehicles or the switch to renewable energies such as solar or wind power. In parallel, toxic emissions reduction need to be focused on in order to give added value to all other environmental efforts.

E.E: What solutions do you bring for these industries?

K.S: Today, ENDEGS is the only company in Europe operating portable vapor control units (VCU) that burn all kinds of gases, gas compounds and vapors of the explosion groups IIA, IIB and, more recently, IIC (products like hydrogen). These systems are equipped in such a way that they can work independently anywhere and the interface to the customer is therefore limited to the essentials. This way, the company helps its customers to prepare for downtime and maintenance, and offers temporary replacement of vapor recovery units (VRUs), flares and vapor processing systems.

https://twitter.com/Endegs_int

https://www.linkedin.com/company/endegsmobilevcu

Kai Sievers LinkedIn:

https://www.linkedin.com/in/kai-sievers-2394389b/