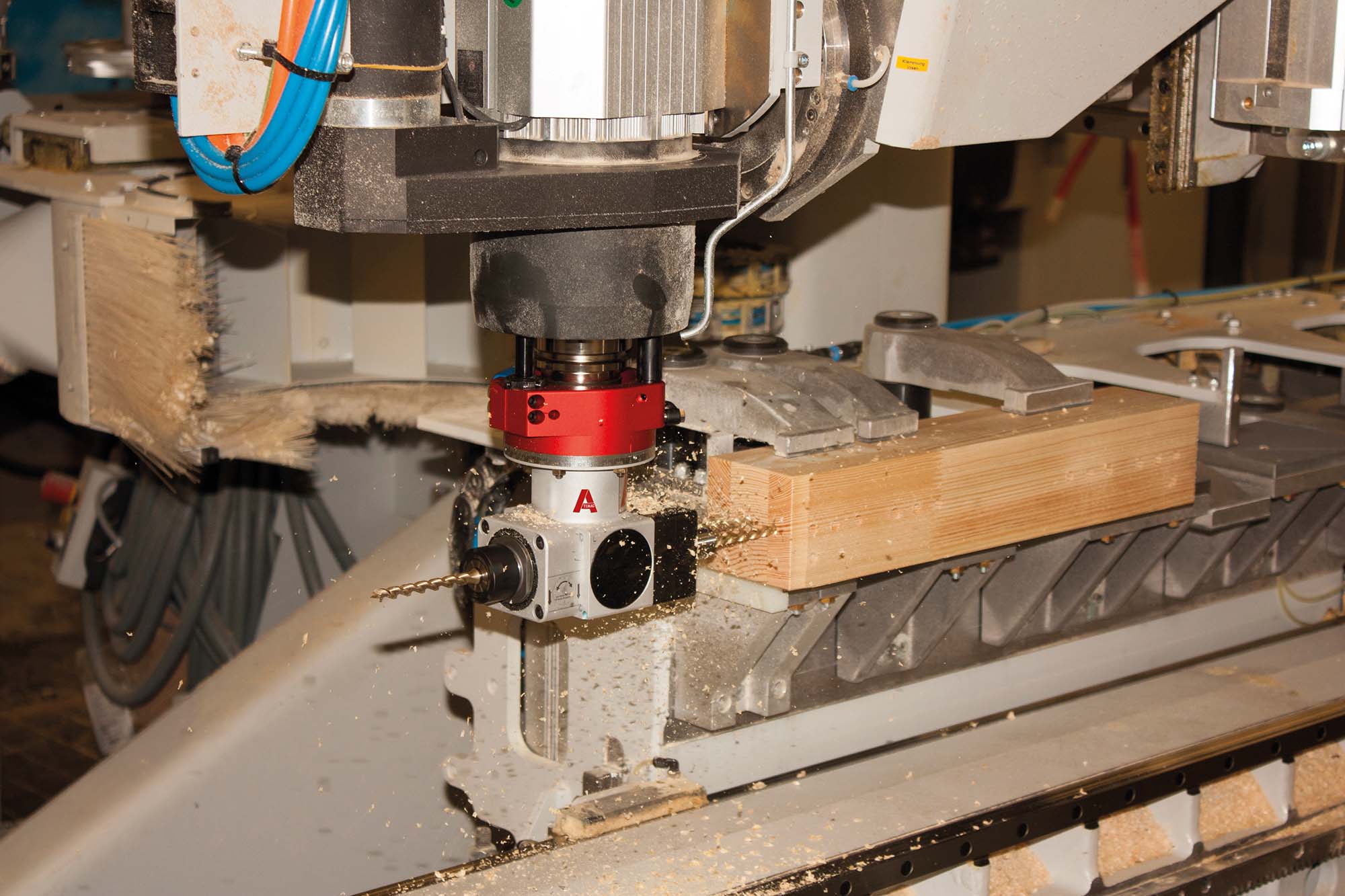

Atemag’s aggregate specialists develop and produce high-performance aggregates and angle heads for machining wood, composites, aluminum, steel, composites and plastics on CNC machining centers and robots.

The individually and handcrafted aggregates can be used to machine a variety of materials at different angles and on multiple axes. Depending on the machining requirements of the applications, standard aggregates or custom-made aggregates are used.

ATEMAG was founded in 2004 to meet the needs of the wood processing industry for products with exceptional quality and outstanding customer service.

Easy Engineering: What are the main areas of activity of the company?

ATEMAG: With the craft production facility, ATEMAG can offer customers individual solutions with the highest quality even in quantity one – #madeingermany.

The development and design team works with the customer and the customer’s partners from the initial idea to the finished product to develop specific and one-of-a-kind products – even with a parts volume of one.

Custom-made aggregates are part of the core business, so the aggregate specialists can often come up with concrete implementation ideas right in the initial meeting. ATEMAG is represented in numerous different industry sectors and provides innovative solutions for realizing challenging processes.

E.E: What’s the news about new products?

ATEMAG: For ATEMAG, the company claim “where needs find solutions” is a matter of the heart, which the technicians from the Black Forest pursue with passion. Thus, the specialists can again present innovative new developments at Ligna 2023, only a few months after the last major trade fair in the wood sector in Germany.

ATEMAG presents another dowel insertion unit. It complements the possibilities of automatic dowel insertion in Holz-Her machines. While the dowel insertion unit, which has already proven itself on the market, is installed as a unit in the CNC machining center EVOLUTION 7405 PinJet from Holz-Her, the “new” dowel insertion unit is now designed for a new dowel & drilling machine PowerPin 7605 from the machine manufacturer.

The dowel unit installed in the machine offers two special new features. On the one hand, different driving depths and dowel projections can be set. In addition, the machine can process different dowel sizes.

The label printer unit, which is used for automated application of adhesive labels to processed panels for simplified picking and labeling, has been upgraded. Significant improvements have been made to the printing speed and power supplies, and it is now much easier for the operator to use.

The ultrasonic aggregate was developed in cooperation with the German company EM Systeme, which specializes in cutting soft materials with ultrasonic. A wide variety of soft materials are cut efficiently and accurately with 20 kHz micro-vibrations. Unusual is the technology that ensures that the aggregate can work autonomously in the machining center without additional power supply.

E.E: What are the ranges of products?

ATEMAG: ATMAG CNC aggregates are used in many different applications, especially in the woodworking industry. They have been used for many years to optimize production lines and enable economical production. These aggregates are used in numerous areas such as staircase construction, interior construction, furniture production, trade fair construction, shop fitting, door and window production, as well as kitchen manufacturing. In addition, CNC aggregates are increasingly used in the production of lightweight materials and optimize production lines in the automotive industry, aerospace industry, and the production of rail vehicles.

E.E: At what stage is the market where you are currently active?

ATEMAG: Always depends how far you will separate your market into detail. Mainly we are working in the woodworking industry, and we do see currently a slightly decreasing market for furniture. If we look to the stairs or window production, we have an increasing market. After 2 years without significant business in composite market, this market is increasing rapidly for 6 months again and we are looking forward to this grow.

E.E: What can you tell us about market trends?

ATEMAG: We see many customers who wants to work high productive with a clear focus on reducing manual work. Our floating aggregates are used to make a constant and defined radius on stairs despite clamping unevenness and thickness fluctuations. The SOFT GRINDER SMART LINE is used to reduce manual rework by sanding paper. Sales of multispindle heads are increasing too – maybe because furniture industry switches from unicolor to directed surface which makes a separate multispindle head very productive on flat table machines.

E.E: What are the most innovative products marketed?

ATEMAG: From our point of view everything which will increase the possibilities on the machine and reduce manual work. A great example is our Label Printer Aggregate which will give the chance to print labels and place them on the workpiece in the machine. The aggregate can be placed in the toolholder and with a mounted battery, we have electrical power for a thermoprinter. Additional we developed a Supersonic Aggregate with a generator inside the aggregate. This aggregate can be placed, even on existing machines, to cut soft materials. On the Holz Handwerk in 2022 we showed our Prototype of our SOFT TOUCH PRO FUNCTION LINE for milling Clamex P Grooves perfectly positioned in the edge of the panel. This year the aggregate is running in the field, and we do see a great opportunity for the kitchen industry as well.

E.E: What estimations do you have for 2023?

ATEMAG: Based on our understanding, we are facing a turning market. There will be business, but not everywhere at the same time. The business will be taken by the faster company. Partnerships and open communication will become a higher priority. Delivery time on the current level will not be accepted by the customers and you must do your homework in terms of internal processes, purchasing, calculation and sales. From ATEMAG we are looking into a bright future because we always focused on customer needs.