ATT InoxDrain© is a production and service company which offers specialized products and individual stainless steel constructions. The experience had been gained since 2002 allows them to comprehensively carry out the entrusted tasks, ranging from technical consulting in the design phase, through the production process up to and including assembly.

ATT is a team of engineers who combines broad knowledge and passion with imagination and many years of experience in their work. The combination of these elements finds reflection in the projects ATT develops and implements. Technical knowledge that is supported by experience in the construction sector and industrial plants, allows them to optimally adapt the comprehensive solutions to the individual needs of our customers.

The sales department is made up of sales engineers who participate in the entire investment process. As technical advisors, they are present at every stage of the contract: during the development of design assumptions, production, assembly and service work.

Interview with Jurij Hawrylak, Export Sales Executive (East Europe and CIS countries) at ATT Inox Drain.

Easy Engineering: What are the main areas of activity of the company?

Jurij Hawrylak: We produce elements of equipment and installation systems for food, catering, chemical and pharmaceutical industries and broadly understood construction and installation sector. We carry out a large number of projects in meat processing (slaughterhouses, chicken farms), fish processing plants, breweries, water bottling plants and any other industry where there is a need in stainless steel products. We are an enterprise open to new technologies, constantly expanding the range of products offered and entering new markets.

E.E: What are the ranges of products?

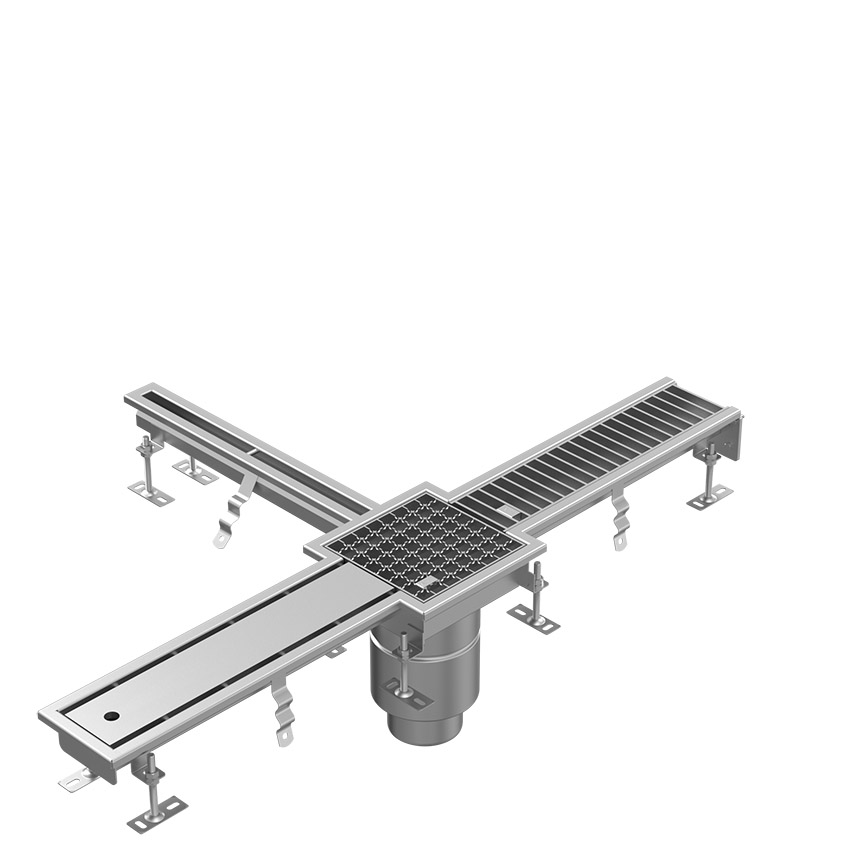

J.H: Today, ATT has an extensive product portfolio, in which the leading positions are stainless steel drainage systems (internal and external), manholes, constructions (platforms, stairs, walk ways), products for industrial plant equipment (for example: bins 200l, 300l, transport rollers), housings and machine elements, and customised products in stainless steel.

E.E: What’s the news about new products?

J.H: With a wealth of experience and a large machine park in our knowledge base, we are constantly at work on developing and adapting our products to the latest technical and hygienic requirements. One of the main strengths of our company is the flexibility in our production. More than 50% of our products are bespoke products. That is to say, we try to offer the exact product that is needed by a customer.

One of the most interesting products are the round channels. Is characterized by more laminar flow in comparison with typical rectangular shape bottom of the channel – faster transfer of fluids to the outlet. User needs less amount of water to keep the channel clean – ecology & efficiency. The discharge of fluids into the channel causes less pollution – reduction of the bacteria accumulation. The product is available in a standard design, according to ATT technology, but we are also able to arm it with additional equipment. For example: special wastewater baskets, basket under the entire length of the channel; hinged grates, etc.

E.E: At what stage is the market where you are currently active?

J.H: Definitely, technically we offer a high-quality product and that we are among the world’s leading manufacturers of drainage systems. ATT is present and has supplied its products to more than 60 countries on 5 continents. We have both representatives and employees in various countries in Europe as well as around the world. Our contact info you can find at the following link.

E.E: What are the most innovative products marketed?

J.H: As far as trends are concerned, they are quite diverse in each region. One of the main trends on the global market right now is the digitalization of your solutions and their adjustments to the needs of the project. We, as a production company, are also trying to move in the course of development.

We have been giving great attention to the certification and hygiene of our products. Since 2022, we have been the official representative of EHEDG in Poland. This gives us the opportunity to share our knowledge and participate in working groups to discuss and clarify standards and guidelines for hygiene in food production.

In addition, we develop our website and provide more and more information for designers and architects, engineers and construction companies who can access our knowledge through our website. In our BIM Library – after a short registration – everyone interested can access our technical drawings (in various formats PDF, DWG, Revit, etc.) and specifications that can be included in their projects. Technical information on our products can also be found on the BIMObjects portal.

E.E: What estimations do you have for 2023?

J.H: The company is constantly grows therefore, our mission is to continue this trend in the future as well. Every year we increase not only the quantity of manufactured products, but also the base of loyal customers, who have been convinced by the quality of our production, come back with new projects. Of course, at the same time we provide full support and service to our ongoing partners. By providing marketing material, production samples, organizing seminars and trainings for their new employees, joint trips to projects and many other smaller activities that are required of them. We also put a lot of work into recognizing our company, we take part in international fairs and we are active on social media like LinkedIn, Facebook, YouTube.

We are open to cooperation, are not afraid of challenges and always provide professional support and service along with our products.