Interview with Yunfan Gao, Marketing Director for Flexiv.

Easy Engineering: Tell us about the difference between collaborative and adaptive robots.

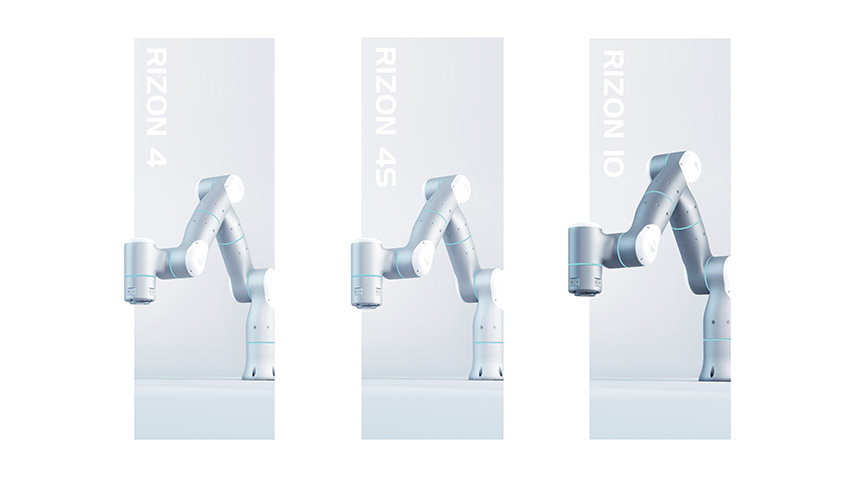

Yunfan Gao: Basically speaking, robots can be divided into three distinct categories. Industrial, collaborative, and adaptive. We are the first company in the world to produce adaptive robots, and we like to think of them as a more evolved version of the collaborative robot.

Although collaborative robots are useful tools, adaptive robots offer a human-like manipulation capability and true artificial intelligence. This makes an adaptive robot easier to integrate and enhances task flexibility and customizability. (https://www.flexiv.com/en/technology/robot)

Easy Engineering: What can your robots do?

Yunfan Gao: Enabled by industry-leading force control, hierarchical intelligence, a powerful robotic operating system, and a human-inspired product design philosophy, Flexiv’s robots are capable of almost any unskilled manual labor tasks and even some skilled labor tasks.

From applications as diverse as pick and place to sanding and polishing, our Rizon range of robots can complete any assembly, surface treatment, material handling, machine tending or mobile manipulation duties. We are also working on integrating our robots into emerging fields, like the medical, agriculture, and hospitality sectors, as innovation is needed in these labor-intensive industries. (https://www.flexiv.com/en/application)

Easy Engineering: What are you most famous for? What advantages does your product bring?

Yunfan Gao: What we are famous for is our sanding and polishing applications. Well, maybe not famous, but in the industry, we are known for it!

Our patented force control technology allows us to sand and polish any surface, regardless of ridges, curves, or other surface irregularities.

I don’t know if you have ever used something like a rotary polisher on your car, but if you use too much pressure, even for a second, it will cut right through the clear coat.

That’s why our robots always keep an optimum pressure while sanding or polishing. When we attend a trade show, we even move an item being polished up and down to demonstrate how our robots can apply constant pressure.

And this is done with a simple off-the-shelf rotary sander or polisher. We attach a bracket that joins the robot to the sander, and that’s it. No expensive tools are necessary.

All you need to do is create a polishing program with our drag-and-drop interface, and then you can start. For a person who understands the system, programming is a matter of a few minutes, and then you can begin your task.

Easy Engineering: What do you think your most innovative product is?

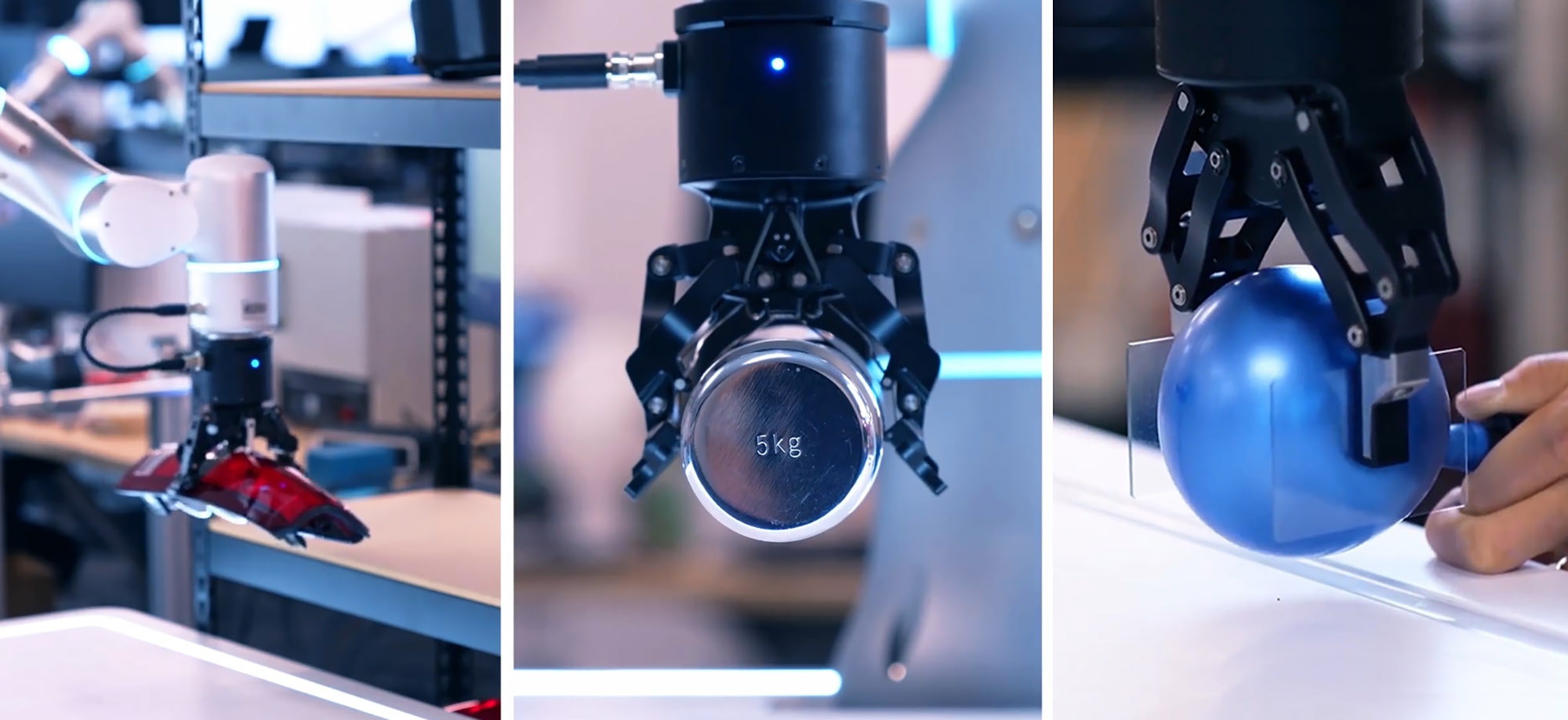

Yunfan Gao: When it comes to our most innovative product, the one that springs to mind is one of our latest releases, the Grav Enhanced gripper. We worked closely with all our clients and discovered that very often, they would need to move a wide variety of objects in a very short space of time. (https://youtu.be/1nqmrDnT16w)

We recognized the need for a gripper that could handle almost any item, so that’s why we created the Grav Enhanced.

It has an extremely large diameter when opened but also features a strip of gecko-inspired adhesive tape running inside the gripper between the two fingers.

It’s unique to the market and can pick up practically anything. From grapefruits and bicycle helmets to soft toys and cardboard.

Some of the Flexiv engineers would have wanted me to say our AnyGrasp system or the NOEMA AI system, but for me, it has to be Grav Enhanced. When you first see it pick up a large spherical object, your first reaction is, wow, that looks impossible. How does it do that?

Easy Engineering: What products / solutions are you going to launch in the future?

Yunfan Gao: Regarding future products and solutions, I will have to be vague. Our R&D department often looks like a scene from Q branch, and we like to keep a pretty tight lid on what’s in the pipeline.

I can tell you, though, that we are working on a more powerful version of the Rizon 10 adaptive robot, and we are also putting a lot of effort into the actual programming of the robots.

We currently use a drag-and-drop menu for programming, but with advancements in AI integration, we are working on an AI development and deployment platform that allows integrators and end users to create custom AI solutions efficiently and effectively.

Easy Engineering: How do your solutions help your clients?

Yunfan Gao: We help our clients by providing robots that are more practical and useful than anything else on the market and by creating complete solutions that can address labor bottlenecks.

We visit each client, help them develop a custom application, provide training, and then guide them through the commissioning process. Although technically, the companies who buy our robots are customers, in reality, they are more like partners. If they have a problem, it means we have a problem, and that’s why we work so closely with them.

For instance, if you are a small manufacturer and produce car spoilers, you can’t get around the fact that it is a fairly labor-intensive process.

Not to mention that sanding carbon fiber or fiberglass is an unpleasant task which requires a fair amount of skill.

Flexiv’s robots, though, could put the raw material into a mold, remove the spoiler from the mold, sand or polish the spoiler, and then place the spoiler in a box ready for shipment.

We set out to build a general-purpose robot, and in doing so, we created a range of robots which can do almost anything. In the case of a spoiler manufacturer, the entire process could be fully automated using our robots.

That’s the key advantage we bring our customers. We can automate a single stage or the entire manufacturing process with one type of robot that is simple to program, reliable, practically maintenance-free, and supremely flexible.

Suppose our hypothetical spoiler company one day received a massive order for spoilers. If that occurred, the robots used for packaging could be re-tasked within five minutes to become part of the sanding and polishing stage. All the customer would have to do is strap on any generic electric sander or polisher to the robot’s end-of-arm tool socket, set the parameters, and then let it get to work.

Easy Engineering: What are your estimations for the year?

Yunfan Gao: I think this year will be when automation becomes mainstream and a part of everyday life. The question will become not ‘why do you have a robot?’ but ‘why don’t you have a robot?’. The last few years have seen labor shortages, wage increases, and the public tightening their purse strings.

All these factors combined are leading businesses and manufacturers to look towards automation as an almost silver bullet that can, at a single stroke, increase their efficiency and reduce their overall costs while simultaneously increasing their productivity.

We’ve seen a dramatic increase in demand over the past three years. Instead of us going to potential customers, they are coming to us and asking how can you help me automate x,y,z. This year, we are forecasting an almost doubling of year-over-year sales.

For businesses who think they can’t afford a robot, my response is, how can you not afford to automate? The average ROI of one of our robots based in North America is nine and a half months. After that period, a Flexiv robot produces pure profit minus the almost negligible running costs.

I think 2023 is going to be an exciting time for anyone involved in robotics and automation, but for us particularly, it’s going to be a year of significant market development and expansion.

To learn more about Flexiv, please visit: https://www.flexiv.com/.

Or send us a message via: https://www.flexiv.com/en/contact.