Automated and flexible production lines offer many advantages. An American dry ice producer wanted to benefit from these, so it worked with Montech AG to transform its manual production.

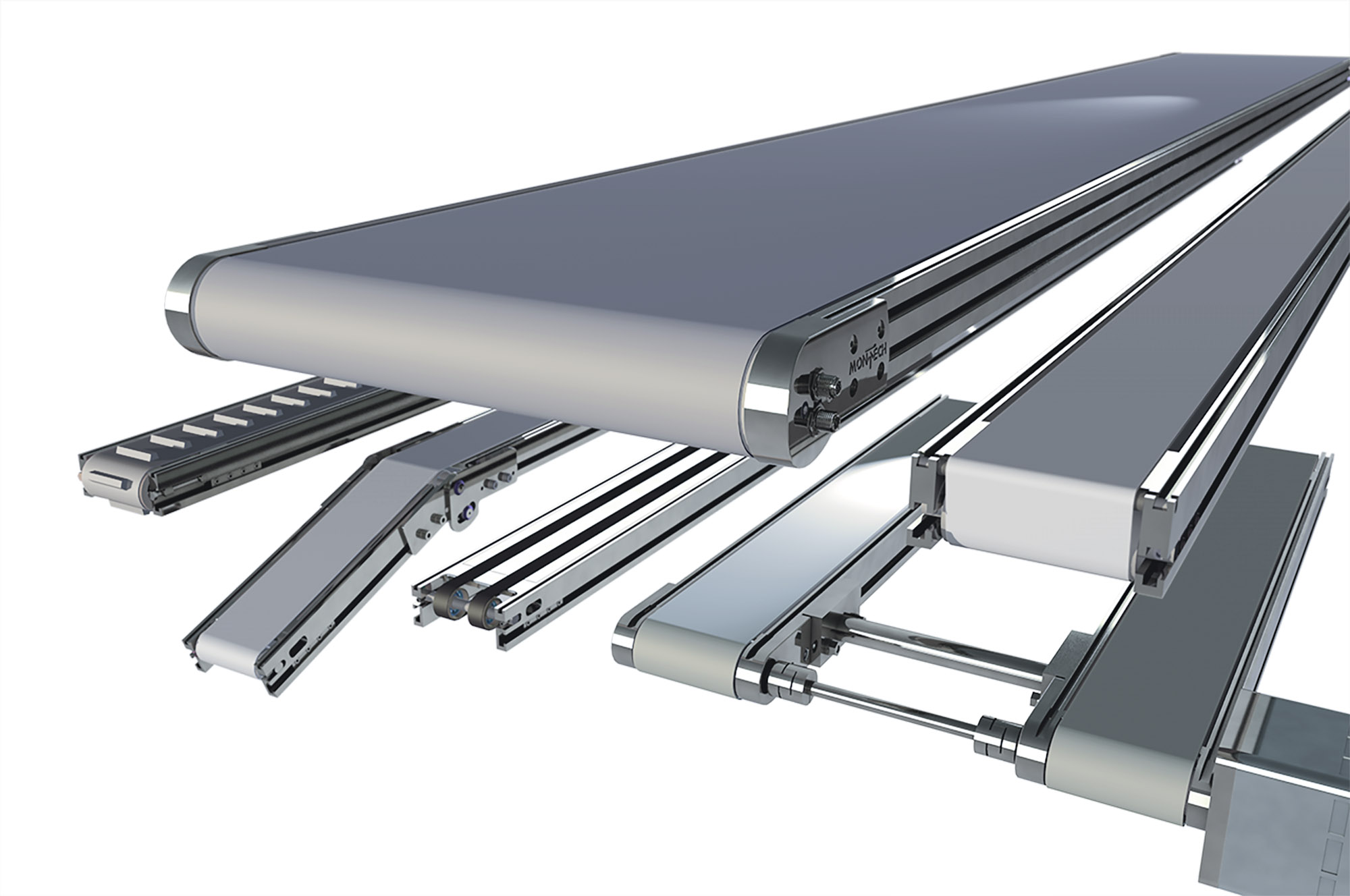

An American dry ice producer wanted greater flexibility and mobility for its production line, and it also wanted to automate manual operations. This company found the perfect partner in Montech AG, a Swiss company that specializes in the industrialization and standardization of state-of-the-art, unusual belt conveyors, transfer systems, and innovative aluminum framing systems.

Various requirements

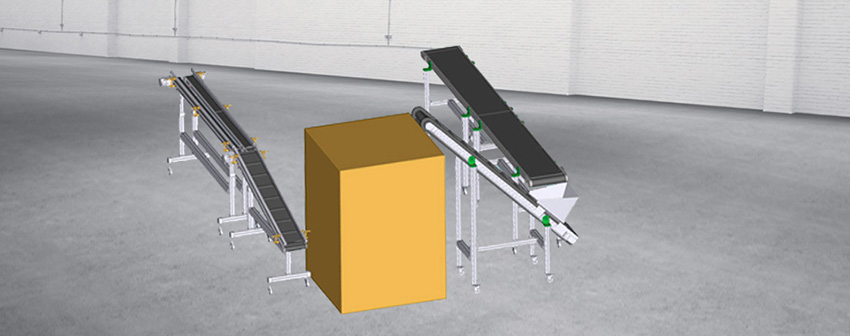

The customer wanted the solution to compensate for the different discharge and working heights of the various machines and to be mobile. It also wanted to be able to move the belt conveyors away when they are not needed. Another request was that there be a way to integrate sawing up ice blocks.

Montech AG solved these problems with a total of five belt conveyors. With two TB40 and three TB30 belt conveyors, it was possible to switch from manual to automated dry ice production. The requested saw blade for the ice blocks is placed between the two TB30 belt conveyors positioned next to each other. Thanks to the incline of the TB30 belt conveyor after the dry ice block machine, there is no need for another belt conveyor or a belt conveyor with a bend. All five conveyor belts have bases with rollers, which provides the desired mobility; if necessary, the belt conveyors can be repositioned quickly and easily.

An automated and mobile solution

The result is an optimized, resource-saving work process. And that’s not all: The mobile base allows the dry ice producer easy access to the processing machine and flexible use for different processing machines. The solution is slim and space-saving thanks to its inclined belt conveyors, and its design is attractive and functional.

https://montech.com/ch/en/solutions/automation-in-dry-ice-production/