Highly and fully automated driving systems have long since ceased to be fiction, but rather represent the future prospects of the automotive industry. In particular, for driving and safety-relevant components such as engine control units, lane departure warning systems and infotainment systems, it is essential to transmit large amounts of data both quickly and absolutely reliably. This is because display or communication failures – for example in navigation systems, parking aids or even indicator lights/telltales – can lead to dangerous situations for the driver and even accidents involving several people. For this reason, automotive manufacturers are already using high-speed data transmission via Automotive Ethernet to network individual control units with each other and with the system network as a whole. In the course of increasing high integration, the future use of Automotive Ethernet as the main bus system is also coming within reach. However, in order to cope with this growing complexity from a safety perspective, existing test methods are no longer sufficient, as they only focus on individual system components and disregard systemic verification. To counteract this weakness, testing strategies for Automotive Ethernet must in future be able to capture the increasingly complex interactions between the individual protocols and ECUs.

Particularly with a view to autonomous driving and the future network architectures in vehicles, Ethernet, which has been established in the consumer sector for many years, is one of the future-proof and promising technologies. The advantages of this type of networking lie in the transmission of high (10GBase-T1, standardized since 2020) but also low data rates (10Base-T1S, standardized since 2019), in scalable fail-safety and reliability, and in the possibility of interacting with the environment via WLAN and 5G, as is the case with so-called C2X communication (“Car to X”). All these aspects relate to both safety-relevant and comfort-oriented areas of driving. Since the founding of the OPEN Alliance in 2011, the integration of automotive Ethernet has been increasing, initially in subsystems of camera/sensor systems, but also in the infotainment area (initially BroadR-Reach, from 2014 100Base-T1, first transceiver ICs from Broadcom).

Image source: ARRK Engineering

Original sources of the standards presented: https://avnu.org/specifications/, https://www.iso.org/standard/69923.html, https://www.opensig.org/, https://1.ieee802.org/

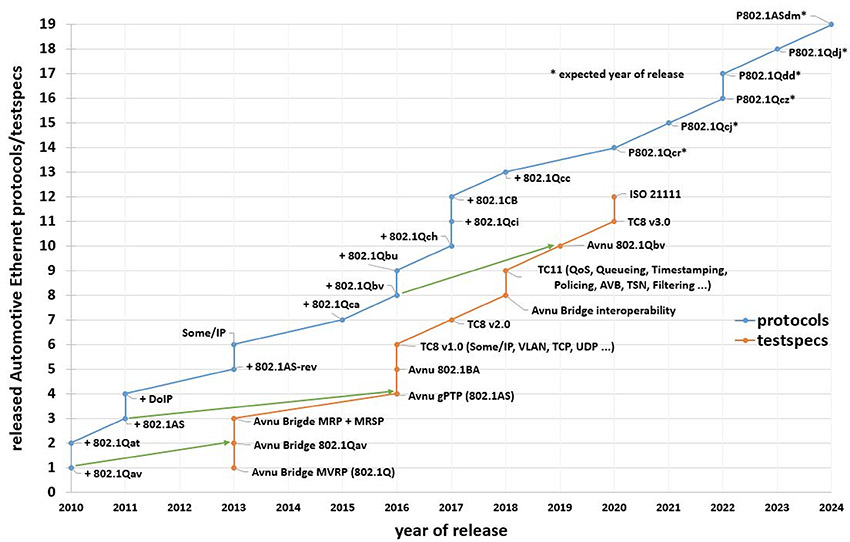

To keep the increasing number of control units for assisted and autonomous driving within manageable limits in the course of this development, an increasing degree of integration of the systems in the vehicle is also necessary, so that fewer ECUs (electronic control units) perform more functions overall. The aim of high integration is to save costs and weight, but this subsequently leads to a proportional increase in software complexity in the system. At the same time, the number of Automotive Ethernet protocols is also increasing (see fig.1) to meet the ever-increasing software requirements. “In order to ensure the continued reliable functioning of systems networking together via Automotive Ethernet, especially highly automated driving systems, it is therefore essential to also adapt the test methodology to the growing complexities,” says Harald Faltheiner, Development Engineer Hardware and Systems Engineering at ARRK Engineering GmbH. “This is because growing networking also increases the interactions between hardware and software layers, which have simply received too little attention to date.”

The step from consumer to automotive Ethernet

Over the past ten years, Automotive Ethernet has become increasingly established as a communication system in vehicle components. In the corresponding test development, the ISO/OSI reference model, which has been standardized for network protocols since the mid-1980s, has been used as a basis. This model assigns the individual processing steps in the signal chain to seven logical layers (Physical, Data Link, Network, Transport, Session, Presentation and Application), which become more abstract towards the top, so that they can be considered in isolation from each other. In contrast, the TCP/IP reference model, which has been authoritative since the development of the Internet protocol family, divides the system with Network, Internet, Transport and Application into only four layers that build on each other and are also each thought of as sections. “This blinkered view of the individual layers no longer does justice to the increasing protocol density,” explains Faltheiner. “Interactions are inevitably overlooked, especially between the lowest physical layer and the higher, application-oriented software layers.”

Source: ARRK Engineering

This discrepancy is due, among other things, to the fact that the Ethernet systems developed since the 1970s in the consumer and business segments differ from automotive Ethernet primarily in the area of the physical layer. This is because while many already established standard protocols, such as TCP/IP, UDP and the IPvx protocols, could simply be adopted or adapted accordingly for use in the automotive industry, the automotive industry places significantly higher demands on the networking technology in terms of hardware, which standard Ethernet with its shielded twisted pair cables cannot fulfill. Automotive Ethernet must withstand a high temperature range – typically up to AEC-Q Grade 1 (-40 °C to +125 °C) – as well as extreme mechanical loads, comply with strict EMC limits, have the lowest possible power consumption in standby mode and also be cost- and weight-efficient. These and other requirements have been achieved over the past ten years through a large number of measures involving adjustments to the hardware and software.

Mastering system complexity through multidimensional testing

The service-oriented Ethernet protocol SOME/IP for inter-process communication for client-server applications was introduced especially for use in the automotive industry, as was the DoIP protocol, which is used for diagnostic purposes. Both operate on the top three layers. Also in the higher layers, AVB/TSN is particularly relevant for automotive Ethernet because it enables low-latency transmission of audio and video data. By extending the TSN standard, protocols for low latency (802.1Qbv, 802.1Qbu, 802.1Qch), high reliability (802.1Qca, 802.1Qci, 802.1CB), and in-vehicle network configuration and synchronization (802.1AS, 802.1Qcc) were added. In addition, IPSec ensures access control, data integrity, authentication and confidentiality. Each of these protocols is already very complex in its own right, which is why the focus in previous test procedures – such as those defined by TC8 of the OPEN Alliance – has been on the respective verification and understanding in detail. However, since all data packets are ultimately transported over the physical layer, this approach completely ignores the closely interwoven interaction of protocols at the hardware and software levels.

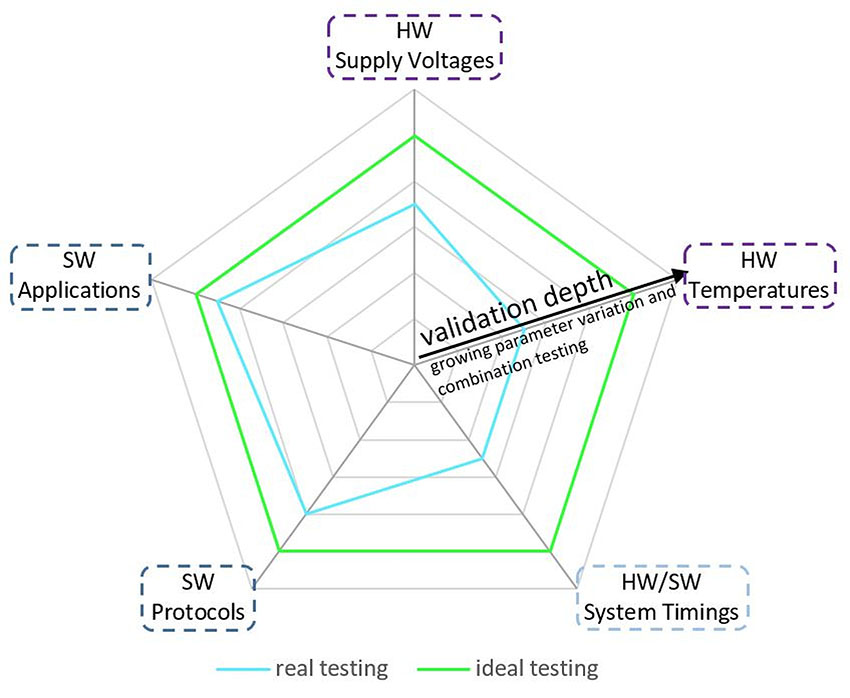

“In order to contain these existing gaps in the testing of vehicle networks, which are growing with increasing complexity, ARRK Engineering has developed a test methodology that covers the entire system from a comprehensive perspective,” explains Faltheiner. The first step of this solution approach is the introduction of an interaction analysis; both in existing and new tests. In this way, control units are not only to be tested in isolation, as is customary with suppliers or manufacturers, but also with regard to their functionality in the system network. In doing so, the specialists at ARRK Engineering basically assume that there are protocols that can lead to malfunctions when interacting with each other. Secondly, the system is specifically loaded so that the probability of unwanted interactions occurring between the control units and the protocols increases. It is essential to apply or change several parameters simultaneously – such as the sum of the functions executed, the voltage, the number of protocols or the timing – and to record and track every step of the test procedure in detail (see fig 2.). On the one hand, this is the only way to define appropriate criteria for evaluating a test as “failed” or “passed”. On the other hand, this ensures that a specific failure, such as the failure of a display system, can also be traced back to a concrete trigger within the system complex.

Automotive Ethernet as the networking system of the future

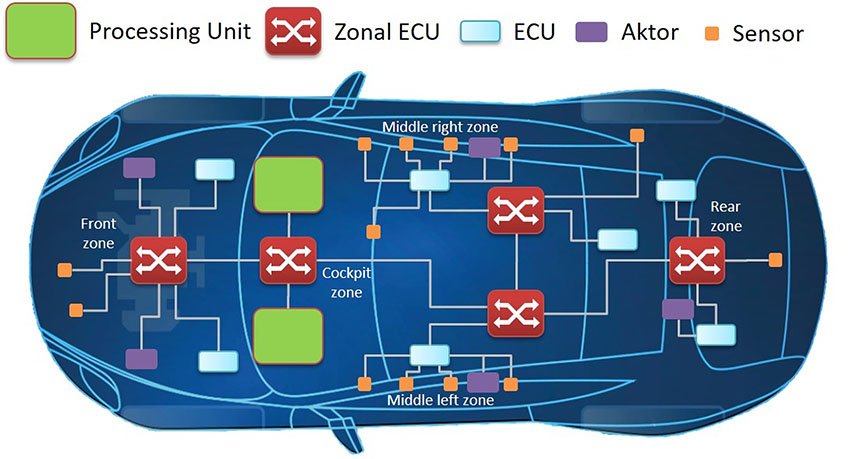

While in most cases today a system architecture with domains and a central gateway is still used and can only be implemented as a subsystem within the Automotive Ethernet, the so-called zone-based architecture (see Fig. 3) is already coming within reach in the course of high integration. This flexible and scalable concept allows networking to take place at the core via Ethernet switches, which forward all the signals. Automotive Ethernet is an adequate networking technology for the zone-based architecture. In principle, there is the possibility of establishing Automotive Ethernet as a system bus sooner or later in the context of increasingly automated driving systems. “In this context, we can assume that the release rate of new protocols for Automotive Ethernet will continue to increase,” notes Faltheiner. “Therefore, it is particularly important to consider the corresponding testability already in parallel with the protocol development and to release both – protocol and test specifications – at the same time.” To address this constant need for further development, ARRK’s engineers pay explicit attention to its future viability in their comprehensive test methodology, so that strategies and concepts can be easily adapted and extended to take into account new protocols.

Source: ARRK Engineering

Good to know:

Developed in the early 1970s at the Xerox Palo Alto Research Center (PARC) in California, Ethernet has been the most widely used LAN technology for commercial and industrial applications since the 1990s. The Institute of Electrical and Electronics Engineers (IEEE) defines Ethernet largely as protocol 802.3, which is primarily used in the consumer and industrial sectors. However, since 2008, so-called automotive Ethernet has also been experimented with as a communication structure for vehicles. This is because as consumer demand for in-vehicle connectivity and advanced driver assistance systems (ADAS) continues to grow, the automotive industry is under constant pressure to deliver competitive, innovative features while minimizing costs. Automotive Ethernet technology enables multiple systems in the vehicle to access information simultaneously over a single unshielded twisted-pair cable. By eliminating the shielded, multi-conductor cabling used in standard Ethernet, automotive manufacturers can significantly increase the resilience of hardware components for in-vehicle applications on the one hand, and reduce their connectivity costs and weight on the other.

The OPEN Alliance Inc. (One-Pair Ether-Net) is a non-profit interest group founded in 2011 by members of the automotive industry and technology providers. The goal of the OPEN Alliance is to promote the adoption of Ethernet-based networks as a standard in automotive applications. Member companies take advantage of Ethernet’s scalability and flexibility to enable cost-effective communication networks in vehicles with reduced complexity. An Ethernet-based communications network is also an important infrastructure element for future features such as autonomous driving and the connected car. Since its inception, the OPEN Alliance has grown to more than 340 members.

Source: shutterstock.com/ZinetroN (edited by ARRK Engineering)

ARRK Engineering is part of the international ARRK group of companies and specializes in product development. With the help of its competencies in Electronics & Software, CAE, Materials, Acoustics, Composites, Body & High-Voltage Storage, Powertrain, Chassis, Interior & Exterior, Optical Systems, Passive Safety, Thermal Management and Digitization & Software, the company develops products for its customers holistically and independently as a long-standing strategic development partner. Within the ARRK group of companies, they implement product developments from virtual development to prototypes and small series production. The locations of ARRK Engineering are in Germany, Romania, UK, the Netherlands, Japan and China. The company employs approx. 1,500 people and is globally active.

Autor: Thomas Zirngibl, M.Sc., Team Leader Cockpit Electronics at ARRK Engineering

ARRK Engineering GmbH

Frankfurter Ring 160, 80807 Munich

Phone: +49 (0) 89 31857-0, Fax: +49 (0) 89 31857-111

Email: info@arrk-engineering.com

Web: www.arrkeurope.com