Easy Engineering: A short description of your company and activities.

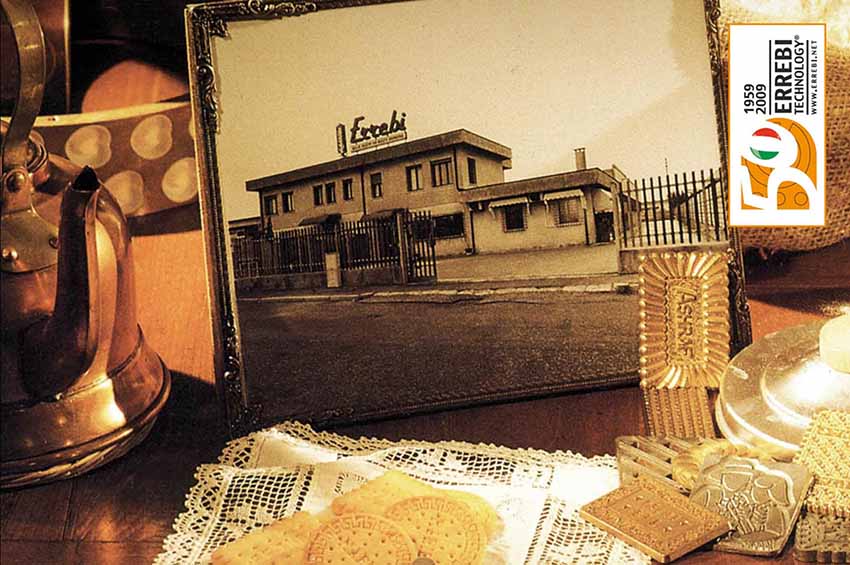

Errebi Technology: Once upon a time…. All fairytales and nice stories start in this way. All traditional novels show that determination, efforts, and simple but deep values get the best results. Today it is not question of Cindarella or Snow-White; today we’d like to tell you the story of Errebi Technology, a company manufacturing biscuit rollers and cutters since ever.

2019 was an important anniversary for Errebi Technology: the celebration of its 60 years: in other words, a perfect age combining long experience of wise old people with the spirit of innovation of the younger generations. Since 1959 Errebi Technology has been producing biscuit moulds and since then, we have captured a major portion of this industry worldwide. During the years, we have been having a continuous growth and increased our investments with high technological machineries and human resources, while still being a family-run company. In 2011 Errebi Technology headquarters moved into a more and efficient building (almost 4 times bigger than the old one) and has being increasing in operating units (CNC machines centres) as well as improved in organization, logistics and production.

E.E: What are the most successful products in your line-up?

Errebi Technology: Biscuit rollers and cutters. That’s all, but not as simple as that! In fact, when you have a biscuit, you enjoy its taste, its crunchy texture, eventually trying to identify its inclusions (sultana, chocolate chips). You appreciate its shape; in other words, you have fun with your cookies (and it is not necessary to be younger than a teenager to do it!). However, beyond this simple piece of baked dough there is a long work of study, design, project and considerations until creating the heart of the whole process: a biscuit roller.

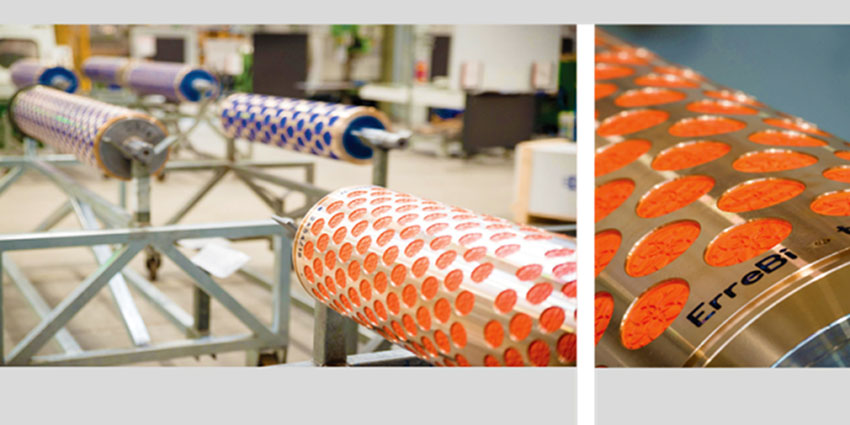

We can identify two kinds of biscuit rollers:

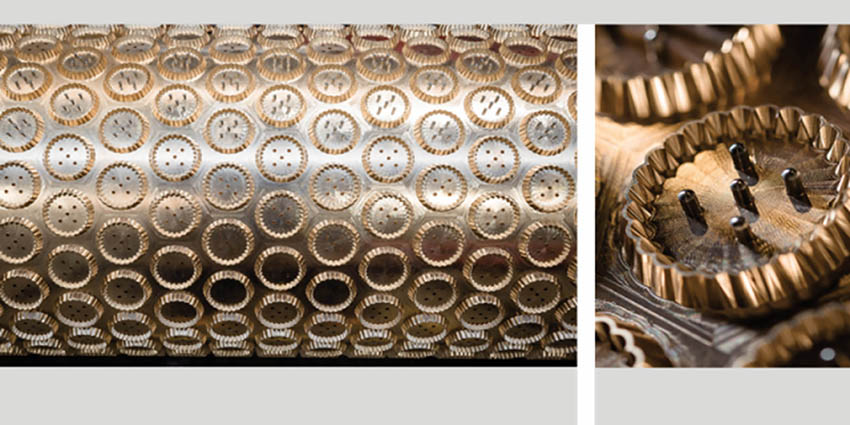

Rotary moulding rollers to be used for soft doughs and Rotary cutters used for cutting a laminated dough sheet. In both cases Errebi Technology engineers pay a lot of attention to the sizes which must compensate spread and shrinkage of the dough during baking, as well as release and high definition of the engraved designed details.

Both kinds of rollers are made with non-toxic materials complying with food regulations.

Both kinds of rollers have a particular geometry on which you recognize staggered or straight rows, pitch of engravings, distance to distance specially designed to exploit the surface of the roller as much as possible but in respect of the distance to avoid sticking of the products to each other.

Both kinds of rollers have construction options: with interchangeable rings, or cups, or solid construction, all customized solutions based on single needs.

And if the roller is the heart of the process, the cavity is the heart of the roller. It is not merely a recessed area to be filled with dough. Here again Errebi Technology do a lot of design projects behind: radius, release angle, compensation in depth are just a few examples of all the parameters our engineers must take into consideration when designing a new mould. The whole to prevent and avoid “tails” on the biscuits, in other words that distortion mainly caused by high speed of abrasive doughs and causing uncontrolled weights, low quality and thus higher costs in the process; but also, to compensate in case of special oblong designs and/or very soft doughs with different depth in the cavity and avoid the so called “Pisa tower” effect and all the problems related with stacking and packaging. From this study it will depend a perfect release, a balanced requested weight and sizes of the final cookie.

E.E: Tell us about the team in your company and how important is the human factor?

Errebi Technology: The fact of being a family-run company since ever. This is the most important human factor. The company started thanks to the great foresight of the founder, Mrs Adriana Masi and her husband Mr. Giovanni Paglione, and followed today by her son, Mr. Massimiliano Paglione. To mention specific names and surnames is not by chance nor attention-seeking. It is rather connected to the fact that in a scenario of companies continuously buying and / or absorbing each other, it is of huge importance to have a continuity in the contacts with customers, which are not considered as merely numbers. Names and surnames, in other words, “people” have a huge importance in the development of a dialogue, based on which ideas, creations, projects “naturally” arise and cancel any risk of “arid” fruitless and sterile assistance. Errebi Technology with its philosophy is deeply convinced that the development of projects is not merely reduced to calculations, but it is a result of exchanging ideas in a friendly relationship with its customers which are not called as such but they are rather partners and friends. In particular, in a field like the biscuit world, where creation, imagination, and rational calculation go side by side, it is very important to have a partner offering you more than a “feedback”. And as such, every day from our design and project dept lots of new designs and ideas are generated always with very tailor-made and customized solutions.

E.E: What can you tell us about products distribution?

Errebi Technology: During the years Errebi Technology Spa has captured a large portion of biscuit market all over the world in an ever-growing trend. From America to Asia our brand is well known by the most important groups such as Mondelez, Pladis, Nestle, Barilla, Ferrero, just to mention a few ones.

E.E: What’s the client feedback for the best-selling products?

Errebi Technology: We can proudly say that most of our customers are word-of-mouth, and once they try our technology, they keep cooperating with us forever. As a matter of fact, fairs mainly represent for Errebi Technology just an occasion to meet our friends rather than capturing more business and our best “visit card” are the references we have all over the world.

E.E: How does this feedback impact development of new products?

Errebi Technology: The world of biscuit is a very dynamic one, and Errebi Technology must always be very ready to respond in promptly to the different requests and needs. More and more difficult, sticky and abrasive dough recipes are for example a great challenger for us to find suitable materials for avoiding these issues. But also, special construction to give more flexibility to our biscuit rollers.

E.E: Tell us about the research and development in your company?

Errebi Technology: As we just said above, need for flexibility has become very topical in a world where everything is changing all the time. And it is even more topical nowadays when incertitude impacts with our habits and forces us to change often our plans. And this happens also in our beloved world of biscuits: following media, social trends, novelty or cartoons themes (we all know children’s power in the market to convince their parents to buy a trend mark rather than another one, influenced by what’s going on for them in terms of movies for example). Besides, also the so called “traditional or classical” brands making the story of a Company might need some restyling and / or some resizing. Or again, the “seasonal” products (Halloween, Christmas, St.Valentine, Easter …).

More and more there are cookies celebrating a season or cookies promoting an event or a movie. But their production life is quite short.

So, if from one side we have a trend toward short life cycles, from the other side, there is the request for re-designing existing shapes. And to facilitate this rapidity in changes, biscuit producers demand more and more fast track route from conception to production. No matter of saying that #Errebi technology is ready once more to play a proper role on this. A special construction permitting you flexible changes married with a performance looking like a solid construction in terms of accuracy and precision.

In other words, if our rollers look like made in a piece only, they are actually made with interchangeable rings and this means “flexibility”

In terms of continuity in production, because the easy change allows you to replace the damage ring with the spare one

In terms of accuracy and precision when testing a new product: a trial ring can give you a 100% precise test in production

But “flexibility” with Errebi Technology is even much more than this: the possibility of regenerating your roller once they are worn or once a cycle of products is over and you don’t produce such a cookie any more. And this allows you to save costs.

And last but not least, a consideration on cookies traditionally made with a different process (wire cut, hard, soft), which might be made with a similar appearance but with a different process. The purpose for this? To save money in the process or to produce something similar but with the available machines…

A biscuit roller here in Errebi Technology is not a simple tool for giving shape to a piece of dough. It’s much more than this. It is the result of long experience and rational considerations to offer you a special tool which can be exploited in different possibilities, always with the accuracy and precision which make Errebi Tecnology different from any other die manufacturer worldwide…

E.E: What is your company philosophy and what drives your company forward?

Errebi Technology: As we already said being a family-run-company with a direct and friendly relationship with our customers is definitely a real asset. And just because we consider the relationship with our customers extremely important, we invite them to visit our premises. As a matter of fact, we have started organizing Conferences in our site: open-door events which have been extremely successful in 2019 and hope we can organize again after this break due to Covid19.

E.E: What guarantees success in your area of activity?

Errebi Technology: Associating Errebi Technology brand with the production of cookie moulds is not complete since our mission is also integrated with full assistance to our customers, supporting them with design ideas and suggestions for the best setting up of all their projects. Additionally, the technology and the choice of materials are fundamental: if from one side they must guarantee the release of extremely particular and abrasive doughs, on the other side the precision in weight and thickness is an essential prerogative for biscuits production. The tolerances in the measurements are essential in an automation process of the lines, as well as uniformity of weight and thickness so that the individual pieces can perfectly match in the creation of the final product. And this has been very well recognized by the major manufacturers biscuits who for years have chosen Errebi Technology as a reliable partner for the success of their projects. And if precision and accuracy are the keywords for the perfect realization of a biscuit mould, we can say that product release and 3D designs are keywords for a mould for the production of special designed cookies, a market that has seen a progressive growth in recent years worldwide. Besides, the search for ever more specific materials is a constantly evolving challenge, without forgetting that these materials are accompanied by certificates of suitability for being in contact with food. In short: who says that Errebi Technology is “only” cookie moulds? As a matter of fact, it is no just this: Errebi Technology is a name that goes beyond a simple cookie mould.

E.E: Give us some details about the after-sales service & customer support?

Errebi Technology: Errebi Technology Spa follow its customers all the time. Our purpose not being to sell just a roller but to build and establish a relationship of confidence and continuity with our customers. We keep a large data archive with all files and historical background of our customers, allowing us to find very quicky the previous data which are if huge importance for a proper after-sales support.

E.E: What can you tell us about market trends?

Errebi Technology: We have seen that with Covid-19 has definitely changed most of our habits and for many reasons the world will no longer be as before. In the field of food, it has been seen how food consumption at home has increased a lot and has gone against the trend with the increase in consumption outside home that had historically occurred in recent years due to the increase in commitments outside home of the whole family. This stagnation of out-of-home consumption is occurring in all areas of the world, from North America to Europe and Asia-Pacific.

In this new reality where the word “uncertainty” reigns supreme, the challenges related to safeguarding and protecting health and the economy are ever greater for each of us.

And in these circumstances the trends that are most recorded are waste reduction, recycling and online shopping.

How does our beloved world of biscuits fit into all of this?

Once again, we are witnessing a consolidation in the consumption of biscuits, as had already been seen in recent months. Many biscuit factories focus their production by optimizing their current production processes and consolidating the production of their most classic products. In fact, it has been seen that in times of pandemics, people are looking for elements giving them certainty and tranquility. And one of these elements can be breakfast, but not made with any products but with food that refers to tradition, to the happiest memories of one’s childhood. It goes without saying that (classic) biscuits therefore constitute a rediscovery, a tool that for a moment removes the climate of uncertainty to make us dive into more carefree moments. Here is how, various biscuit factories, riding the wave and responding to the needs of consumers, offer the same products of the past, possibly made healthier (without palm oil, without added sugars …) to encourage more consumption, persuading the consumer that the organic or health products can definitely contribute to a stronger immune system.

We remind you that for the realization of this range of particular products, special rollers are required in terms of materials (to have good release from the mould even with increasingly critical doughs and to resist the abrasion of recipes that are increasingly rich in cereals, dried fruit, inclusions) , as well as in terms of designs.

E.E: What are the most innovative products marketed?

Errebi Technology: The most innovative products are biscuit rollers for special cookies. Baked but not fried snacks, recovery scrap designs, resized restyled cookies, luxe-premium biscuits, seasonal biscuits, sustainable diets and healthy products, puzzled 3D designs, special flavors added to the recipes… are just an example of the long list of new special products we are facing nowadays. Errebi Technology is always at the side of its customers to assist them in the best possible way, whatever the shape, the design or recipe to be made.

ERREBI TECHNOLOGY SPA

VIA Ca’ Mignola Nuova, 1290

45021 Badia Polesine (Rovigo)

Tel.: +39 0425-51934

Mail: contact@errebi.net

Website: www.errebi.net