The awareness of protecting our environment, reducing climate-influencing factors, protecting the population from harmful environmental influences and maintaining the natural environment (flora and fauna) is increasingly permeating our society. Appropriate measures are taken accordingly, laws and regulations are being adapted – and a general change in awareness has been noted.

In order to reach all these goals, constant innovation is necessary.

ENDEGS provides a mobile service to industry to mitigate harmful – hazardous or/toxic – gas emissions. This applies where the existing infrastructure fails or is not (yet) properly installed or where gas accumulations have occurred unplanned. The aim is to reduce harmful emissions more effectively and extensively in the long term.

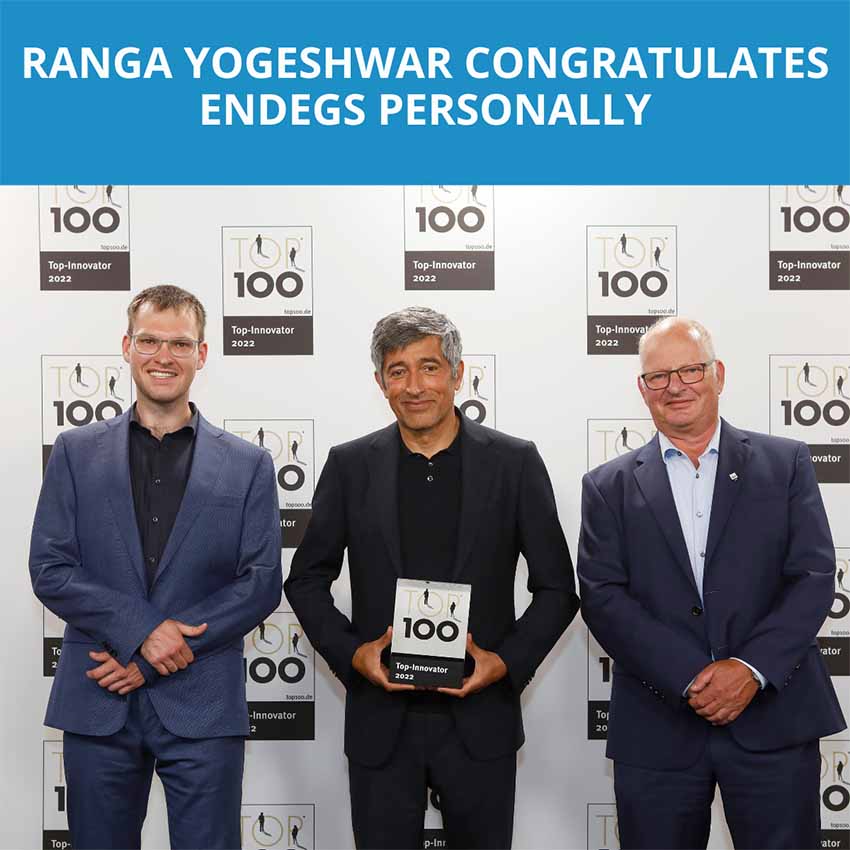

This offer is relatively new on the market and is subject to new requirements, which ENDEGS successfully tries to meet through constant improvements and further developments. This innovation concept of the company is confirmed, among other things, by the award as one of the 100 innovative companies in Germany in 2021 and 2022.

Tank degassing has become standard nowadays. But when it comes to difficult challenges – for example, the degassing of ammonia, butadiene, ethylene, or more complex projects like turnaround or special customer process requirements, partners are needed that can offer solutions for just these challenges. ENDEGS, with its well trained staff, efficient processes and flexible patented combustion units, is such a partner.

Interview with Kai Sievers, CEO ENDEGS Group.

Easy Engineering: Which are the most innovative products/solutions in your lineup?

Kai Sievers: Offering a mobile possibility of temporarily pollutant disposal is already innovative in itself.

ENDEGS’ mobile combustion units are scalable from 0.1 to 50 megawatts and the combustion rate is close to 100 %.

Since 2022, ENDEGS has 3 MW plants in addition to the 20 MW and 10 MW Vapor Combustion Units (VCU). These VCUs are particularly suitable for short projects that last only a few hours – such as accidents or emergency operations. After arrival and official approval, the project with a 3 MW incinerator can start immediately.

With the new mobile evaporator with nitrogen tank, even complex gases can be safely burned to over 99.99 %.

ENDEGS cooperates with the port of Duisburg (Duisport) for the environmentally friendly degassing of inland tankers and gas tankers. Approval for the degassing activities is available. ENDEGS has a very suitable plot of land with quay facility.

The degassing station, the first of its kind in Germany, enables gases and vapors to be burned by a safe and fast process – regardless of the size of the tank and the gas mixture and its concentration. ENDEGS provides on-site the appropriate mobile incinerators in IIA, IIB and IIC, including personnel for connection and disconnection, but also additional material such as power units, pipes, fans, detonation arresters, liquid separators and pressure control valves.

E.E: What was the research behind the products/solutions?

K.S: The original thought behind ENDEGS was: Isn’t good air equally important? And if that is the case, why can we smell tank cleaning activities outside the plant? Can’t we do something about that?

Yes – and now, ENDEGS is part of it. Our technologies give industry a way to noticeably reduce emissions. So that more and more industries and thus all of us can benefit from this, the ENDEGS team is constantly researching and developing, and extending the applications of our technologies. This way, we realize as much combustion performance as possible in a minimum of space with the lowest possible fuel consumption.

In order to achieve this, we use the experience from our realized projects and always adapt them to the current market conditions.

E.E: Tell us about their innovative features?

K.S: The most innovations and innovative features behind our products:

- Design patented.

- Minimal installation work on site

- Less space required

- No clean up after job is done

- No visual flame

- No odor

- No ground level radiation

- Full complement of safety equipment

E.E: How important are these features for the users?

K.S: These factors have high priority for our customers in industry. This is confirmed by regular feedback, such as the statement “ENDEGS’ technical competence provided a quick and efficient solution to our problem with strict compliance to safety and environmental regulation.”

E.E: How do these features help the users?

K.S: Above all, they help with simple and uncomplicated use. Business can continue and the customer’s involvement is reduced to his own procedures.

In addition, our customers can reduce their impact on the direct neighborhood and overall environmental impact because of the elimination of toxic gases and smell nuisances.

One of the most important things is the safety during the process. Due to our mobile combustion units, no employees are exposed to harmful gases that can damage their health in the long term.

In addition, for the customer there is a reduction of cleaning time, downtime and overall costs.

E.E: What industries do you think will grow in 2023?

K.S: We think, that there will be a massive change and movement in the “green” industry and related services. Since expertise is lacking in many places, consultants with many years of experience are more important than ever.

E.E: What products/solutions do you provide for these industries?

K.S: We offer the products and services already mentioned. In addition to degassing, we also offer a robot for remote tank cleaning for rent.

Our goals and the associated solutions for our customers are:

- Further reduction of toxic and harmful emissions in industrial maintenance

- Protection of workers involved in the degassing process to the greatest possible degree

- Prevention of creation of hazardous waste, as sometimes happens through the use of other technologies.

- Further reduction of the operating materials.

- Addressing of new applications where degassing was not formerly used, and where gases and vapors are still released into the atmosphere.

E.E: How will you adapt your products/solutions for the future?

K.S: We are continuously improving our services and technologies and help for adjacent improvements. Our experience is a key asset.

E.E: What are your estimations for the rest of the year?

K.S: In the long term, we expect an increase in demand for environmentally friendly options for degassing and tank cleaning in the different industries.

Our vapor combustion units, N2 vaporizers as well as our rental ATEX Zone 0 robot for a remote-controlled tank cleaning are already well booked until the end of the year on national and international projects like turnaround on refineries, as temporary replacement of gas engines like VRU or VPS or during barges and sea vessel loading/unloading.