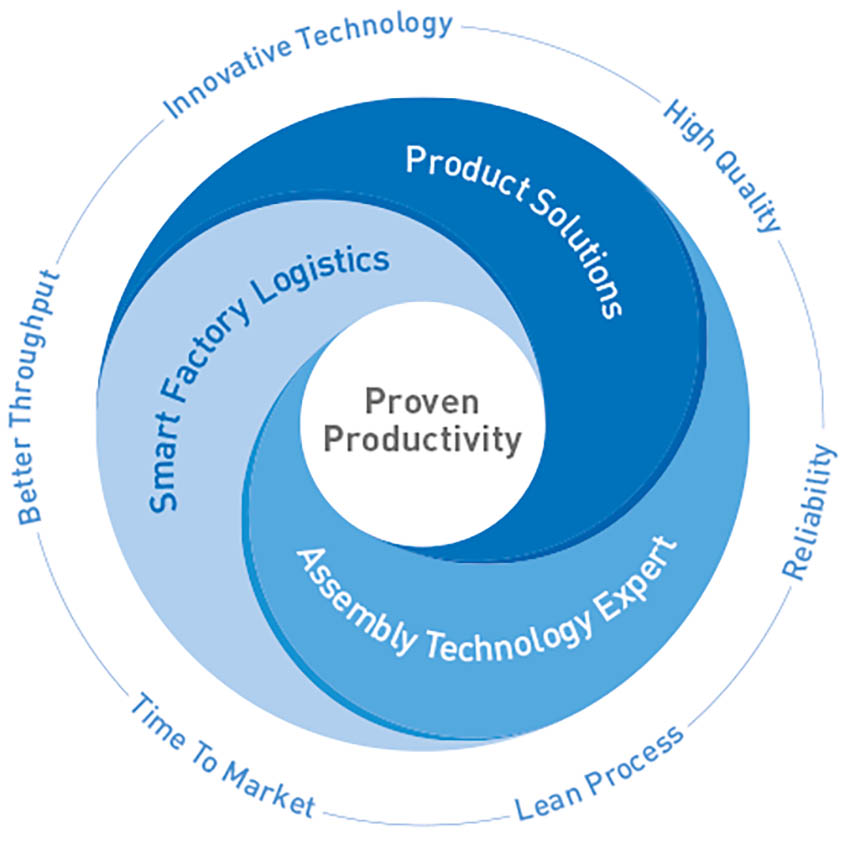

Bossard offers the highest quality in fastening technology serving OEM’s worldwide. The company provides proven expertise in many markets including Automotive, Rail, EV, Industrial Automation and Robotics. Whether your fastening challenges are in Electrical or Mechanical Engineering, Bossard has a solution for your application.

Interview with Katharina Hüthmayr, Director of Sales at Bossard and KVT Austria.

Easy Engineering: How was 2022 for your company, a brief summary?

Katharina Hüthmayr: 2022 was a very successful year for us. We exceeded our expectations. Regardless of the regional crisis in Europe which led to material cost increase, we were still able to acquire new customers and spread out our know-how to new industries.

Furthermore, we were still very focused on the main industries such as electric vehicles, automotive, medical, and overall high-tech manufacturing industries. Customers of these industries saw the added value we brought them and that resulted in a successful 2022 for us.

E.E: What products/services have you launched this year?

K.H: In 2022 we launched numerous product innovations, however, what was more important for us was that we introduced and implemented our 3 different services to many of our customers.

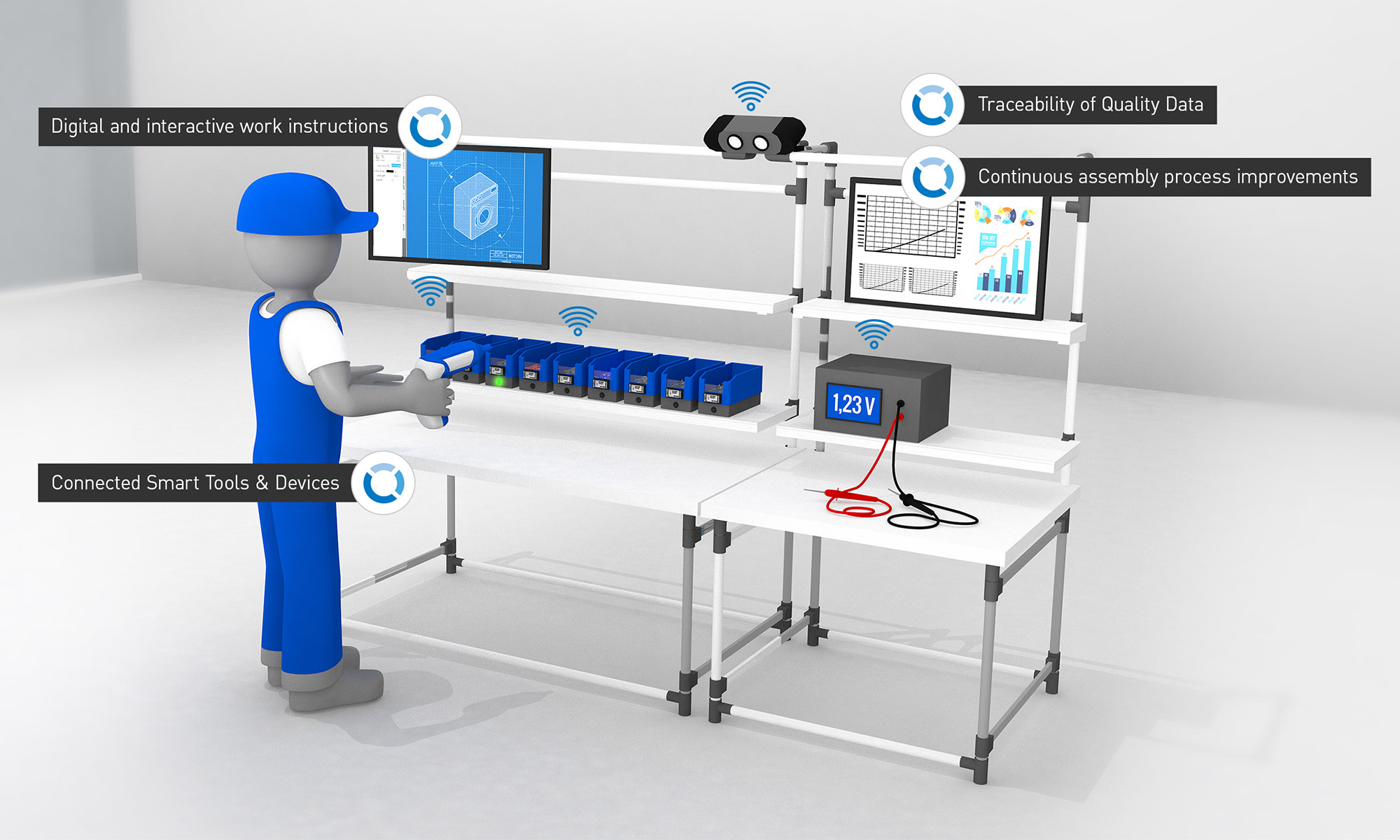

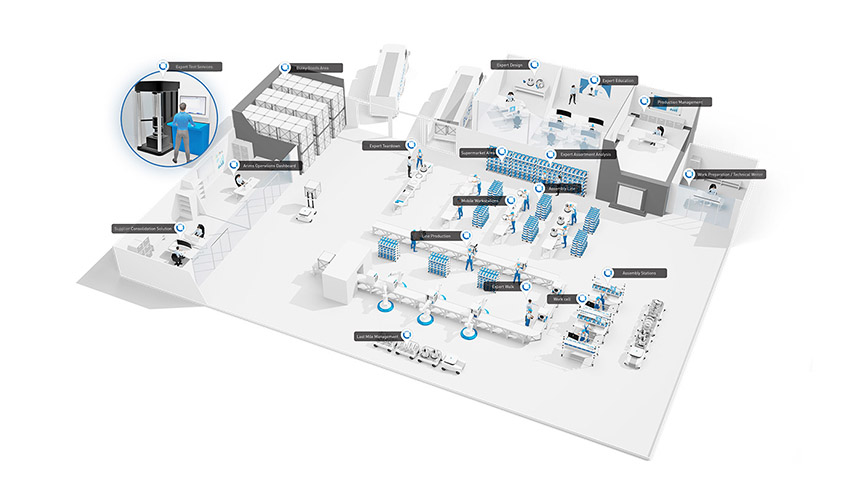

The first one is the Smart Factory Assembly (SFA) service. With SFA service, we help our customers in digitalizing their manual working stations and process. The digitalization of the assembly is the key for many factories to secure lean processes and quality assurance.

The second one is ATE, Assembly Technology Expert. This comprises several different engineering services, from design, testing, and reverse engineering to assortment analysis. Especially in reverse engineering, we have done several projects of disassembling the customer’s products, analyzing each component, and giving advice on how to reduce the cost of the product by replacing it with smarter, better, and more competitive fasteners.

The third one is Smart Factory Logistics, which helps customer to automate their ordering, warehousing, and logistics process. The state-of-the-art logistics system driven by IoT brings reliability and transparency to the customer’s C-parts management.

E.E: How has the market changed compared to previous years?

K.H: Specifically about the Romanian market, we see that it is growing and rising a lot. We see that many companies built up their engineering competence centers in Romania and there are many very well-educated talents locally. That brings many companies from Germany, France and Austria, for example, to set up their engineering departments in Romania.

E.E: What are the new challenges in your field of activity?

K.H: Since the engineering competence of many companies has been largely moved to Romania, we also have to be close to these engineering departments locally and be on the side of the engineers at all times. Our activity is no longer just about selling products, we are on our side with our customers to support them as consultants of c-parts from the engineering phase.

Romania is also a very fast-moving market in terms of high expectations in consulting and responding to questions and deliveries. We need to outperform our competition to satisfy Romanian customers’ needs.

E.E: How have you overcome these challenges in this more competitive environment?

K.H: The key is definitely to have good people and teams locally to be able to serve the customers. We have very competent people who move and react fast to customers’ needs, and who are well-educated and experienced to consult customers. With a good sales team, we are convinced that we will grow in the future.

E.E: Tell us about product innovation and how it will affect the future?

K.H: The Smart Factory Assembly service we offered is an innovation to digitally transform customer’s assembly process.

With digital and interactive work instructions, the work instructions can be centrally managed, paper can be reduced, and the onboarding process can be dramatically shortened. The connected smart tools and devices can ensure the assembly quality and every step can be documented and traced. And the traceability of the quality data offers the process transparency and quick improvement possibility.

This can dramatically improve customers’ assembly process and the way of manual assembly work.

E.E: How will product innovation help customers?

K.H: One of our customers in Austria is the OEM of medical devices, they have decided to implement Smart Factory Assembly for multiple reasons. One of them is to meet the high standard of quality requirement of the FDA, therefore it is necessary to have an assembly process in which every fastening torque is preset and documented. The work instructions are easy to set up and to be adjusted for the revision of the product. The onboarding process for the new staff got a lot easier and the quality control takes place automatically in digital form at every work step, so that there is no need for paper documentation.

All in all, it is all about saving the Total Cost of Ownership for the customer. When we speak about the cost, most people see only the 15% visible cost, as the tip of the iceberg. However, 85% of the invisible cost, which is the bottom of the iceberg, is often neglected. The time spent on the onboarding and paper-based documentation, the effort spent on adjusting the instructions for the revision, and the tracing of the assembly step when it comes to the problem all result in invisible costs.

Our product innovation is aimed at helping customers to reduce the overall cost by largely reducing the invisible cost.

E.E: What are the trends in the markets you are currently active in?

K.H: The trend we see in c-parts supply is about the availability for the customer, the speed to respond, the professionalism, and the localization of the sourcing. Outsourcing from Asia is at the moment over due to these requirements. Customers expect to get what they want at the time they want.

This also results in the trend that the sales process becomes longer and is no longer just about selling the fasteners but is more about the services, supporting the customers for their projects, and offering the know-how throughout their engineering process.

When it comes to the industry, we also see the growing demand in the sunrise industries such as e-mobility and heat pumps.

E.E: What do you think will be the trends next year?

K.H: Quality requirements and reliability are getting more and more important than ever before.

Also as mentioned previously, being close to our customers and supporting them from an early stage is the trend now. That is why we have also started with resident engineers on customer sites. We agreed with the customer to implement a fastening engineer at their location so they can consult him directly about the fastening challenge in their R&D process.

E.E: What are the prospects for the rest of the year?

K.H: We are focusing even more now on the sunrise industries, such as e-mobility, heat pumps, and superchargers, and Romania is also an active market of these industries. So we are very convinced that we are going to grow our markets overall, and especially in Romania.

Internally we are also transforming our sales process by emphasizing more on digital marketing and lead generation. This helps us target the right customers more efficiently and effectively and enables us to have more resources.

Contact Information

Bogdan Manea

Account Development + Technical Expert

Mobil: +40 724 511 400

E-Mail: bogdan.manea@bossard.com

KVT-Fastening GmbH | a Bossard company

Im Südpark 185

AT-4030 Linz/Pichling

KVT-Fastening SRL. | a Bossard company

Str. Grigore Cobalcescu, nr.46

010196 Sect.1, București

Evie Liu

Head of Marketing

Phone: +43 732 25770044

E-Mail: evie.liu@bossard.com

KVT-Fastening GmbH | a Bossard company

Im Südpark 185

AT-4030 Linz/Pichling