Brdr. Christensens, a Bliss Anand group company, is one of the premium manufacturers of lubricated plug valves, steam jacketed plug valves and double plug double isolation valves, mainly used in the global oil and gas industry.

The company is located in Haslev, Denmark on a sprawling land area of 44,000 Sq Mtr with 16,000 Sq Mtr of workshop (which includes Foundry, Machine shop, assembly unit, painting, inspection and Testing facility) and office facilities and it is involved in the production of Lubricated Plug Valves since 1958.

Easy Engineering: What are the ranges of products?

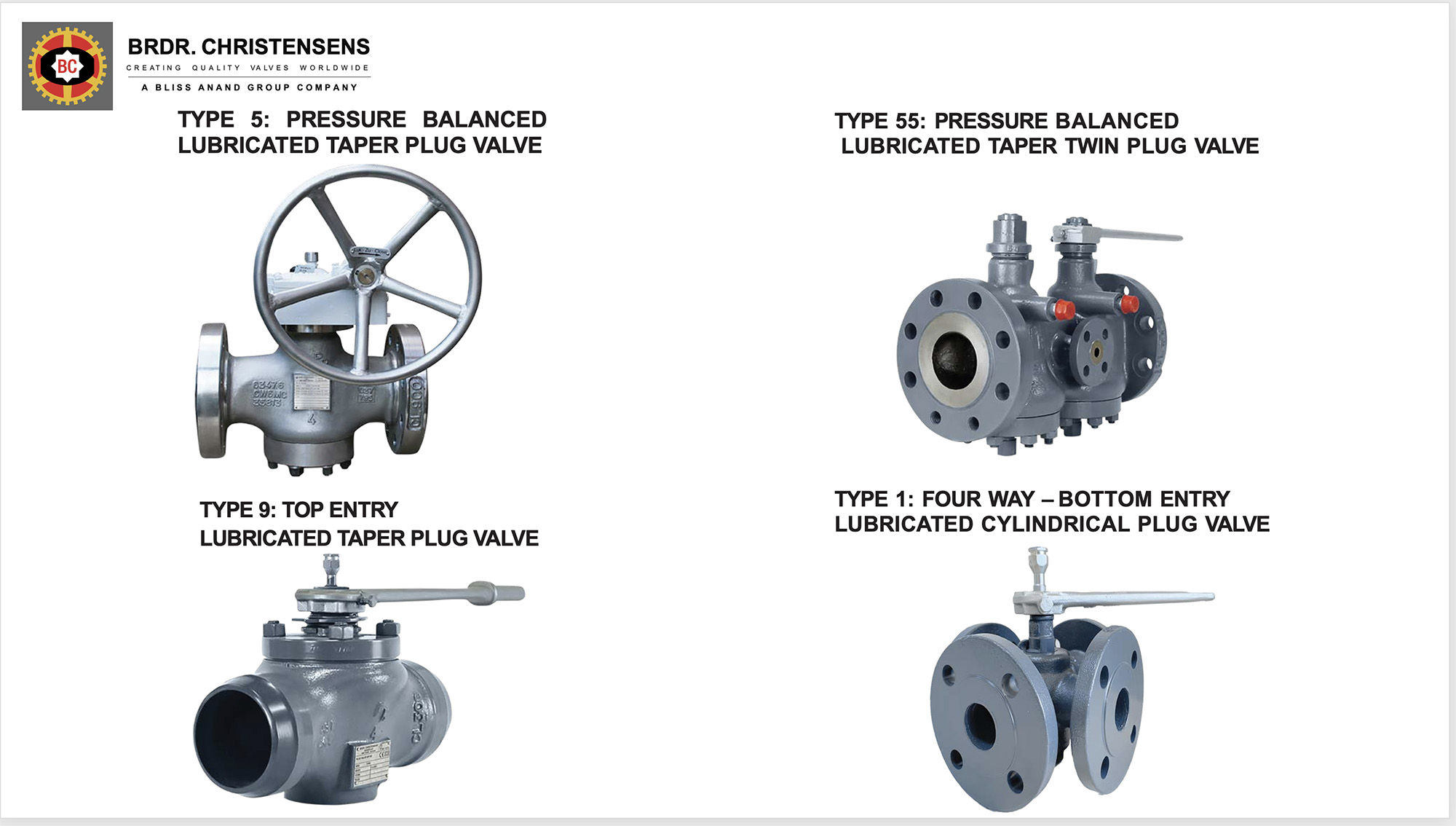

Type 5 : LUBRICATED TAPER PLUG VALVE

API/ASME/PED/EN/ISO/ATEX/NACE

½”-36” / DN 15 – DN 900

Class: 150/300/600/900/1500/2500

PN 20/50/100/150/250/420

Key Features:

- Trouble-free metal-to-metal sealing

- Blowout Proof Stem with three independent seals

- Pressure balanced and fire safe design

- Regular, Venturi or Short pattern

- Port Type: Rectangular, reduced or full port

- Limitless installation positions

- Low Torque

Type 55: PRESSURE BALANCED LUBRICATED TAPER TWIN PLUG VALVE

API/ASME/PED/EN/ISO/ATEX/NACE

1”-24” / DN 25 – DN 600

Class: 150/300/600/900/1500/2500

PN 20/50/100/150/250/420

Key Features:

- Double Block and Bleed (DBB) and Double-Isolation and Bleed (DIB) capabilities

- Trouble-free metal-to-metal sealing

- Blowout Proof Stem with three independent seals

- Pressure balanced and fire safe design

- Venturi pattern

Port Type: Straightway, rectangular or reduced port

- Limitless installation positions

- Low Torque

- Cavity Relief System

Type 9: TOP ENTRY LUBRICATED TAPER PLUG VALVE

API/ASME/PED/EN/ISO/ATEX/NACE

½”-36” / DN 15 – DN 900

Class: 125/150/250/300

PN 10/20/40/50

Key Features:

- Trouble-free metal-to-metal sealing

- Fire safe design

- Regular, Venturi or Short pattern

- Port Type: Rectangular, reduced or full port

- Limitless installation positions

- Low Torque

TYPE 1: TWO WAY, THREE WAY AND FOUR WAY – BOTTOM ENTRY LUBRICATED CYLINDRICAL PLUG VALVE

API/ASME/PED/EN

½” – 30” / DN 15 – DN 750

Class: 125/150/250/300

PN 10/20/40/50

Key Features:

- Trouble-free metal-to-metal sealing

- Regular Pattern

Port Type : Two Way, Three Way and Four Way, Regular double L-ported

- Limitless installation positions

- Adjustment free and blow out proof trim

- Low Torque

E.E: At what stage is the market where you are currently active?

We deliver valves to all Major Oil and Gas companies in the world, where they are used on onshore, offshore and on large gas transmission and compressed stations. BRDR Christensen is approved as manufacturer of Lubricated Plug Valves by most of the Oil and Gas Companies worldwide, which includes:

- Saudi Aramco

- ADNOC

- Qatar Petroleum

- ExxonMobil

- Conoco Philipps

- Equinor

- British Petroleum

- Total

- Shell

- North Oil etc..

It’s also only 1 out of 3 worldwide manufacturers to have top tier NOC approvals.

E.E: What can you tell us about market trends?

We see lot of Gas related projects being awarded in Middle East, Europe and North America and our products finds good application in these markets as they perform well in the high pressure and high temperature. Comparative advantages of Plug Valves with Ball Valves are as follows:

| PLUG VALVE | BALL VALVE | |

| Seating area | Up to 30° on each side of the port | Seating area extends 3-5° on each side of port |

| Sealing | Metal to metal seating of plug to body to effect sealing | Small metal seat ring pushed up against Ball effects sealing |

| Sealant system | Fully contained sealant system used as a backup seat, this system is ”contained” between the 30° seat of metal. This is a fully pressurized area of high-pressure sealant | Sealant system is contained within the seat ring but the trapping is by way of only 1½-2½° of metal seats found in seat ring |

| Body cavities | Very few and small body cavities. Little chance of any sediment collection. Corrosion is less of a problem due to minimal line fluid collection points | Relatively large and numerous body cavities. These can fill with line sediments or precipitants |

| Exposure of seating area upon final closure or initial opening | Upon final closure or initial opening the entire seat cross section is not exposed to full line velocity across seats. This ”shielding” of seat cross section minimizes possibility for damage at the most severe and critical seconds of any valves service life. It is at this time that line velocity is at it’s maximum and erosion can damage valve seats | Upon cycling, at times, 100% of seat cross section is exposed to full line flow / velocity. Velocity at these moments is at the greatest and thus most erosive state. Also, this occurs at the same point on the seating area upon each and every cycle of valve |

E.E: What are the most innovative products marketed?

All our DBB valves are designed with the patented CCR System which avoid overpressure in the inner cavities between the 2plugs.

All DBB valves are designed with a bore going from the body sealing surface against the diaphragm, to the port outside of each plug. Normally this bore is kept closed by the pressure of the bottom cover, if the pressure in the cavity increases more than normal, it will automatically open to the bore via the diaphram .