Brown and Mason are Europe’s premier Industrial demolition, dismantling and decommissioning contractor. The company offers a complete contracting service for: power stations, refineries (and other petrochemical sites), factories and all other kinds of industrial infrastructure.

Interview with Daniel Baker, Contracts Director at Brown and Mason Group Limited.

Easy Engineering: A brief description of the company and its activities.

Daniel Baker: Brown and Mason was incorporated in 1961, based in the United Kingdom (UK) and The Netherlands (Brown and Mason BV), Brown and Mason specialize in providing safe and efficient demolition, dismantling, and decommissioning services across the UK and Europe for a variety of industries, including nuclear, industrial, commercial, and residential and today are now a fourth-generation successful family business. From humble beginnings, Brown and Mason started with just £400 (US$250), now 62 years later, the company is established itself as one of the largest industrial decommissioning, dismantling and demolition companies in the world and are the largest single producer of scrap metal in the UK.

With over 60 years of experience in the industry, Brown and Mason have earned a reputation for excellence, reliability, and innovation. Brown and Mason, to our vast portfolio, have been completing industrial dismantling in the power sector dating as far back as the 1980s, circa 20 years post the corporation of Brown and Mason, where large UK facilities, including Beckton and Greenwich, were undertaken. Now operating a structured Integrated Safety Management System, Brown and Mason have full accreditation to ISO 9001, ISO14001, ISO45001, and other Health and Safety accreditations and have decommissioned and dismantled over sixty (60) power generating plants and hundreds of other significant projects ranging from <Net£500k to >Gross£50m.

Beckton

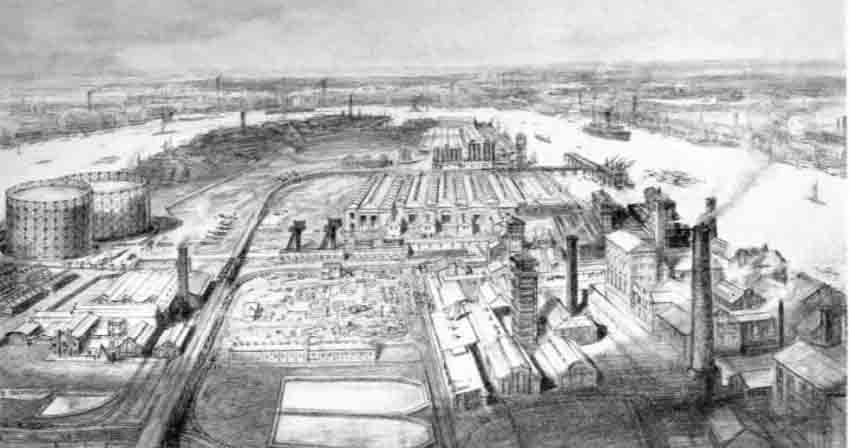

The gasworks at Beckton was once a thriving industrial area in the borough of Newham which played a major role in London’s East End industry for over 100 years. Formerly the largest gasworks in Europe, Beckton Gasworks was in use from 1870 to 1969, when it closed down.

Between the 1970s and 1980s Brown and Mason worked extensively decommissioning and dismantling the site.

Beckton had its own piers on the River Thames and could store a quarter of a million tons of coal at once. The company brought coal into the plant for manufacture and had a thriving business selling the by-products of gas production that it did not use itself. At one point, the gasworks ran 17 collier ships of its own and ran an extensive internal railway on site. At its peak, the gasworks employed 10,000 men.

The Beckton Gas Works in Films

Following the decommissioning process, some of the concrete structures were retained, the part dismantled, and derelict state of the site made it an ideal location for filming. Brown and Mason undertook a vast amount of enabling works, breaking holes in concrete structures and making modifications to suit filming in a surprising number of Hollywood movies, the initial enabling works were undertaken for a Hollywood film, perhaps best known becoming Vietnam in the Stanley Kubrick film “Full Metal Jacket”.

The breaking of the concrete structures and enabling process, including making safe, provided the derelict state which was perfect for a war-ravaged landscape, although it has to be said that Kubrick’s dynamiting of areas within the site left it in a far worst state than when he started!

The gasworks also appeared in the opening sequence of the James Bond movie, “For Your Eyes Only” and was used for London scenes in the film Nineteen Eighty Four. Oddly, the location was also used in the John Wayne film, “Brannigan”.

E.E: What are the main areas of activity of the company?

D.B: As an enabling works contractor, Brown and Mason fulfil the role of both Principal Contractor and Principal Designer for the execution of, but not limited to, decommissioning, decontamination including asbestos removal, traditional demolition, dismantling, structural alterations, explosive engineering, ground engineering, bulk earthworks, and ground remediation.

Brown and Mason are a member of ARCA, a trade association in the UK that represents asbestos removal contractors and associated businesses. As an affiliated member of ARCA, Brown and Mason is committed to providing and promoting safe and professional asbestos removal practices, guidance, and support to ensure compliance with all the relevant regulations and guidelines with Brown and Mason BV holding an asbestos trading license in The Netherlands, Brown and Mason work closely with regulatory bodies, industry associations, and other stakeholders, ensuring best practices and sharing knowledge and experience in the field of asbestos removal and management, Brown and Mason have completed, at the time, the largest asbestos removal in Hungary (in excess of 35,000 c.m.).

The heavy industrial demolition sector is a sector where the structures are vastly more complex in nature and size and requires strict processes and analysis to assess the safety risk to employees working at height for long periods of time. Over many years Brown and Mason have fully tailored systems to deliver power industry projects, the success and reliability of these systems are unrivalled….. “Why are we unrivalled…?” The lessons learnt, and negative connotations associated with the risks are continuously elevated to become mainstream topics, it is only the sheer volume of successfully delivered power industry projects that makes this possible for our systems to be trusted and as a business, trusted.

E.E: Where we are currently active?

D.B: Brown and Mason are currently active in England, Scotland, Wales and The Netherlands, with a works order book currently scheduled until 2028, Brown and Mason have a stable pipeline of secured works, with progressive negotiations on projects in Greece, Spain, Portugal and the UAE.

Our commitment to investing in the most modern plant is borne out by our present large comprehensive fleet ranging from 1t mini excavators to 250t super high reach excavators. Our track record in the industrial market has enabled us to move into other markets, and we now offer both nuclear and marine decommissioning, dismantling and demolition.

Business success has promoted natural growth, Brown and Mason and their in-house experts strive for a greater and bigger future seeking further opportunities across the UK and European markets.

Achievements and innovation

Brown and Mason’s Health and Safety record was rewarded at The Supplier of the Year Global Awards by Spanish public multinational utility company Iberdrola in Madrid for the works being undertaken at Longganet Power Station, Scotland, soon to be completed end of August 2023.

Brown and Mason were recently awarded British Demolition Contractor of the Year 2022 at The British Demolition Awards, and Brown and Mason Explosives Manager Rikki Isgar, the only directly employed Explosives Manager in the UK, was recently awarded the NFDC Demolition Manager of the Year for his outstanding standards, achievements, leadership, community engagement and the continuous drive for improvement.

Through our YouTube channel, we were contacted by the London Science Museum to contribute to their new gallery TECHNICIANS: THE DAVID SAINSBURY GALLERY, which demonstrates how engineers change the world.

Brown and Mason have demolished the tallest free-standing structure in Scotland and the tallest concrete structure ever to be demolished in the United Kingdom.

Brown and Mason engineered and achieved a world-first (and to date last) demolition operation of two chimneys striking each other on their downward trajectory.

Further feats and a stamp on the positive legacy of Brown and Mason lies with Brown and Mason BV’s success in the explosive engineering on Centrale Gelderland Power Station, Nijmegen, The Netherlands. This feat of engineering was one of, if not the largest explosive event of a power-generating plant in The Netherlands. To achieve the designed collapse, we utilised 116m of linear cutting charge in 111 locations, adding 264kg of bulk explosive, 1500m detonating cord, and 1055 detonators and connectors. In addition to the onsite constraints and obvious need for precise timings due to the conflict in Ukraine, we could not source the preferred selection of delay detonators and connectors as these were being supplied from out of the country. This led to an already complex delay sequence becoming even more complex to ensure we retained the desired timings and collapse mechanisms.

Passing on Savings.

In the past 25 years, we have processed around 3.5 million t of ferrous scrap metal arising from over 60 power plants we have decommissioned and dismantled. This does not take into account other projects worked on during the same period, which would take the total to around 4 million tonnes.

We have built up long-standing relationships with the major ferrous and non-ferrous merchants in Europe, and this has enabled us to obtain the best prices in the marketplace. This also enables us to pass on savings to our customers, in the form of lump-sum credits within the engineering contract.