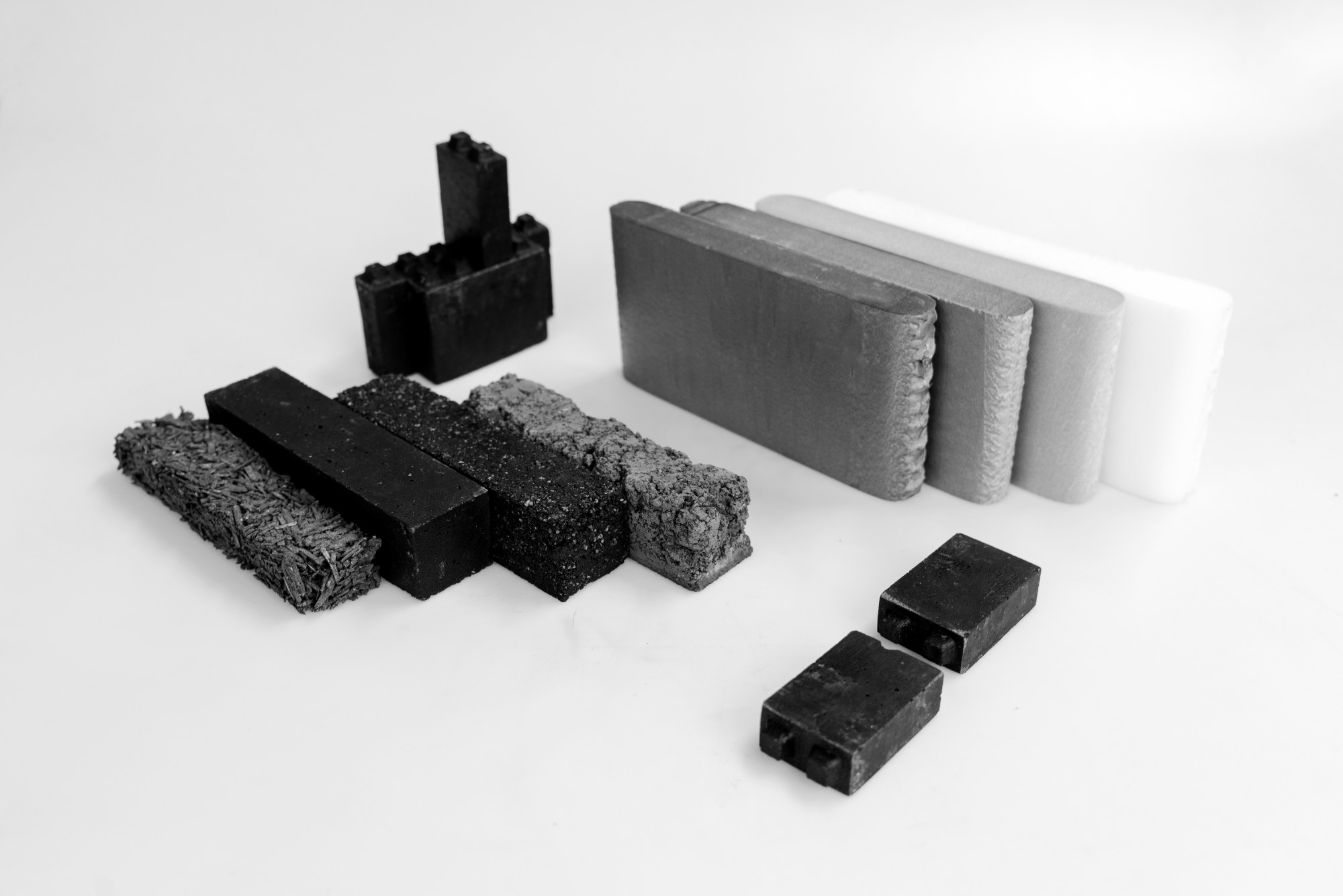

carbonauten is a Germany-based biochar company. Through pyrolytic carbonization they produce what is called “technical biocarbons” from woody biomass residues. Those biocarbons are ground up and mixed into conventional materials. This way our goal is to produce CO2-negative products for agriculture and the polymers industry in large quantities.

Interview with Aaron Ertler, Head of communication at carbonauten.

Easy Engineering: What are the main areas of activity of the company?

Aaron Ertler: The carbonization of woody biomass residues is the first step. Therefore, we are active in the biochar industry.

In agriculture through the use of biochar in the soil for the creation of Terra Preta.

In the polymers industry through plastic compounds mixed with technical biocarbons.

carbonauten is also doing research on mixing biocarbon into concrete and asphalt to develop CO2-negative construction materials. That would be a real game changer in the fight against global warming.

E.E: What’s the news about new products/services?

A.E: Our first production site, the minus CO2 factory 001, in Eberswalde (Brandenburg, Germany) is now operating. The foundation stone has been laid for the second plant in Chibi (Hubei, China) for the large-scale carbonization of bamboo.

In the area of applications, we recently injection moulded plastic seat shells for high-speed trains in a project with Deutsche Bahn. With up to 16% technical biocarbon in the plastic.

E.E: What are the ranges of products/services?

A.E: Our products will be, on the one hand, CO2-negative NET Materials. (Negative Emission Technology), and on the other hand ready-to-use minus CO2 factories for our industrial partners.

Carbonization is of course an exothermic process with excess energy as a by-product. Where companies need climate-neutral energy, we are in talks about carbonization plants at their production sites.

E.E: What is the state of the market where you are currently active?

A.E: Biochar is a so-called low-hanging fruit in the fight against global warming. A huge potential but the prices for biochar (and also the CO2-certificates generated) are still to high.

E.E: What can you tell us about market trends?

A.E: Many companies are scaling up their production quickly. That’s good for the earth’s atmosphere.

carbonauten doesn’t have competitors, only comrades-in-arms in the fight against global warming. The batch-retort system that we have developed can definitely contribute something because it doesn’t have any moving parts, therefore isn’t prone to malfunctions and can carbonize huge amounts of biomass residues quickly.

E.E: What are the most innovative products/services marketed?

A.E: Minus-CO2 plastic compounds. Climate-neutral energy through process heat, pyrolysis oil and pyrolysis gas, and the carbonauten attitude, purpose and strategy.

Fuck CO2.

E.E: What estimations do you have for 2024?

A.E: The estimated revenue will be 5.4 million EUR.

In the Eberswalde production site, we will put up our own compounder and start producing Tech BioC compounds ourselves, without having to rely on foreign compounders. In Chibi we will put up 2 carbonization modules this year. Furthermore, we will expand to the ASEAN countries, the US, Canada, Africa, Scandinavia, Eastern Europe and the Balkans and we are looking for brand ambassadors.