Alpine Metal Tech is part of Montana Aerospace AG and a world leader in the field of special machine building for the Steel, Railway, Automotive and Aerospace Industry.

Montana Aerospace AG is a leading producer of system components and complex assemblies for the aerospace industry, with worldwide engineering and manufacturing operations. The Company has approximately 4,800 highly skilled employees at 28 locations on four continents – designing, developing and producing ground-breaking technologies for tomorrow’s aerospace, e-mobility and energy industries out of aluminum, titanium, composite, copper and steel.

The focus of the Alpine Metal Tech Group lies on developing, designing, manufacturing and servicing special machines. While the headquarter is situated in Regau, Austria, the eleven different locations around the world use their synergies in order to create customer advantages, such as service networks and cost-efficient engineering. As a group, we guarantee a comprehensive and customized service offer for every phase of the product life cycle of the so far 10,000 machines installed worldwide. According to customer requirements, individual service packages are supplied, consisting of machine service, spare and wear parts, consumables as well as modernization of machines.

Along with the newly integrated brand of INTERMATO in 2020, the Group of Alpine Metal Tech consists of the well-known and established brands NUMTEC, GEGA, KNORR, MAKRA, AMAKON, MAGNEMAG and SIMULATION with focus on innovation and technology leadership.

IMT Intermato: high performance vertical CNC lathes

Last year, Alpine Metal Tech could expand its horizontal diversification in the business fields of Automotive and Railway by taking over the well-known machine builder IMT Intermato S.p.A. in Italy. The know-how in vertical lathes and deep whole drills for the production of aluminum alloy wheels as well as the innovative railway equipment completes the already existing product portfolio. The Italian manufacturer proposes solutions for part sizes from a few tens of millimeters of diameter up to 6 meters and more. Despite the core business of vertical lathes designed for light alloy wheel machining. Several series of machines are tailored for the aerospace, railway, gas and oil industry.

Vertical lathes with a capacity up to around 1200 mm of diameter and options such as self-loading configuration and drilling and milling operations are offered as well as totally modular and customizable machines. Designed and manufactured according to the specific requirements of the customers.

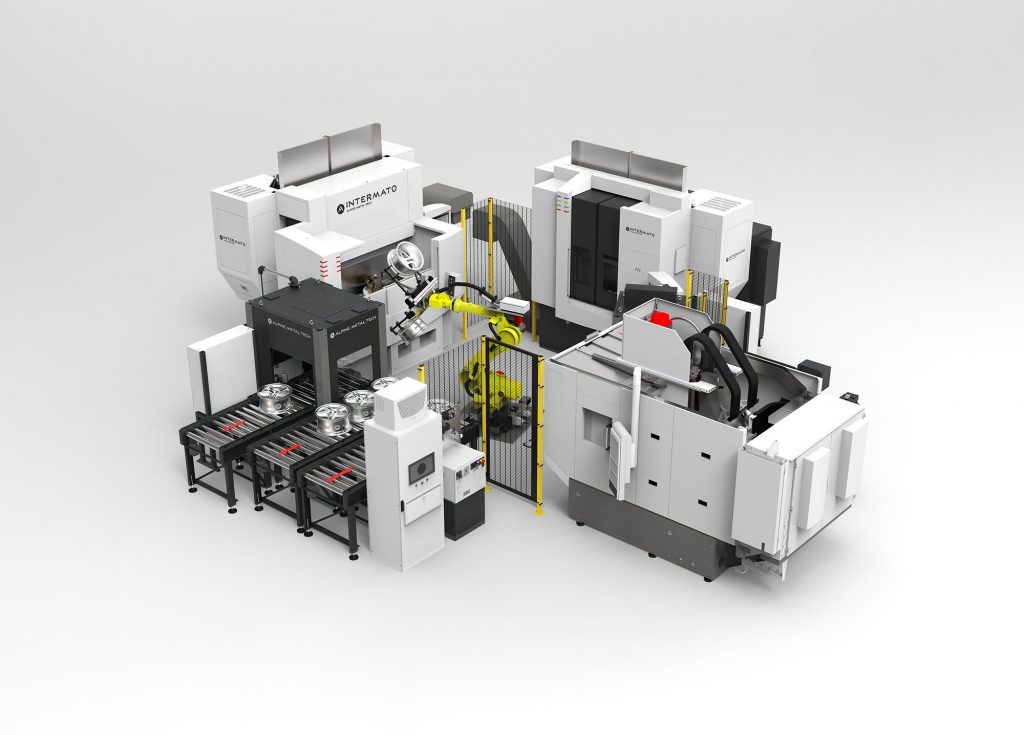

Fully automated robot cells are the result of intercompany synergies at its best. The robot cells impose with the know-how in the field of CNC processing by INTERMATO and the laser measurement and inspection technology by NUMTEC. Due to the modular expandability, customers are able to modify their machine according to individual requirements and benefit from a single source supplier.

Steel Industry: Continuous Casting and Rolling Mills

In the area of steel, Alpine Metal Tech offers a wide range of special machinery for the continuous casting process as well as rolling mills. The largest steel producing factories trust the brands of GEGA and NUMTEC in the field of powder feeding, shroud manipulation, online and offline torch cutting as well as deburring. Since continuous identification of products has become a basic requirement for all modern steelworks, Alpine Metal Tech marking technologies by NUMTEC and MAGNEMAG provide this as customized solutions. Our strength lies in combining machines for the permanent and high-resolution marking and the subsequent real-time identification and inspection.

Railway Industry: Rails and Wheels

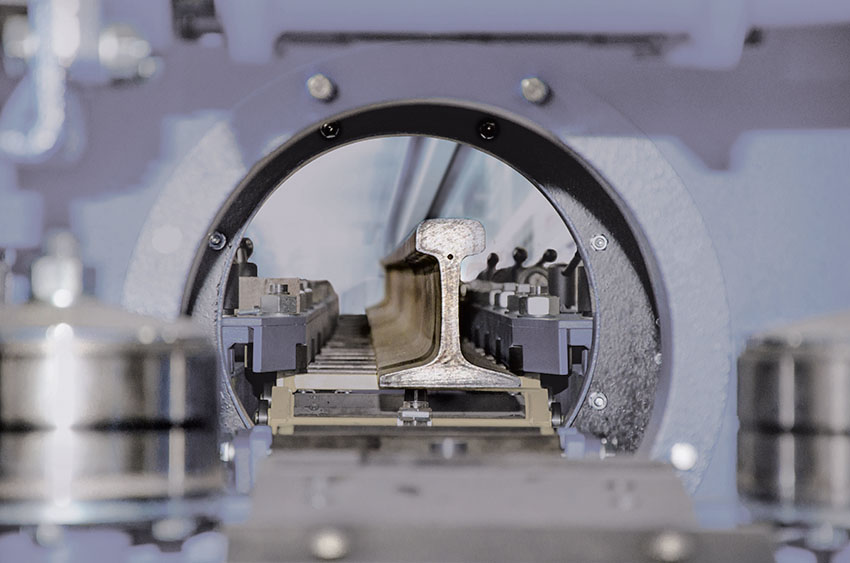

With the brand KNORR, Alpine Metal Tech is a leading provider of optoelectronic measuring and fully automated inspection of rails. The turnkey, nondestructive inspection lines comprise brushing machines for measurement preparation, measurement gauges for profiles, surface and flatness measuring units, eddy current testing units to detect surface defects, and ultrasonic testing units for internal defect detection.

With INTERMATO, Alpine Metal Tech could extend its portfolio with special machinery for the production process of railway wheels. The product scope ranges from CNC vertical lathes to advanced production technologies for the complete machining including roughing, turning, finishing and even drilling.

Automotive Industry: Production, Testing and Measuring

In close cooperation with the automotive industry and the leading vehicle wheel manufacturers, Alpine Metal Tech has developed an extensive repertoire of production, testing and measuring systems that guarantee the quality and safety of the finished products. Top quality equipment optimizes the aluminum wheel manufacturing process and creates conditions for stable and efficient production with the lowest reject rates and highest product quality in the industry.

During the manufacture of aluminum wheels, a special cast parts coding process developed by Alpine Metal Tech is conducted to automatically guide the unfinished parts through the entire finishing process and direct them to the various processing operations. Alpine Metal Tech machines remove castings and sprue points, facilitate the work process by means of high-level automation and ensure safe process control via product marking using bar code or data matrix codes as well as customer-specific labeling. The combination of modular machines concepts and new laser measuring techniques further increase productivity. In order to meet all standards, regulations and safety requirements Alpine Metal Tech NUMTEC and MAKRA testing and measuring machines cover all mandatory safety standards given by inspection organizations such as TÜV.

Fire Training Simulators for the largest Airports worldwide

Within the division Aerospace, Alpine Metal Tech is a leading provider of training simulators for every fire-related eventuality. The tailor-made live fire simulators, which are designed to help firefighters to train the case of an emergency, range from civil and military aircrafts to maritime training vessels of any kind as well as gas and oil fire simulators. One of the largest Airport worldwide – Chicago O´Hare International – has already been equipped with state-of-the-art simulators by Alpine Metal Tech’s brand SIMULATION.

Glaze into the Future: Automation and Robotics

In times of Industry 4.0 and Digitalization, the in-house global research and development department of Alpine Metal Tech focuses on sector-independent automation solutions. Despite all challenges of the last year, the time has been used for developing the new machine generation ADoC – Automated Deburring of Casting – a disruptive innovation, deburring casting parts fully automatic. The development, a robot application equipped with a laser measurement system and a milling tool has already been awarded with the Upper Austrian innovation prize. In order to provide our customers cost-efficient solutions and optimized, digital production processes, innovations in the fields of automatization, camera and vision systems, laser measurement techniques, robotics, and remote installation complement the group’s portfolio.