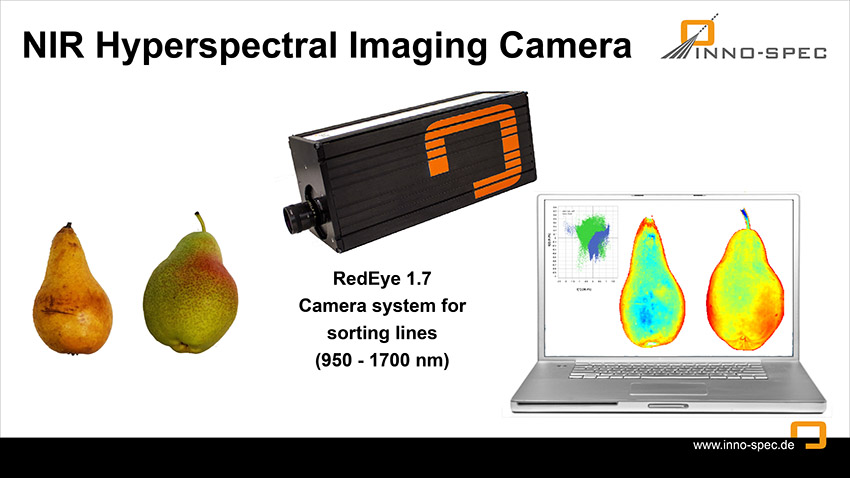

There are many ways for that kind of projects. In general, a machine building company wants to achieve higher economically value and increase their setup in terms of new sensors and then technology. One of these technologies is Hyperspectral Imaging. In Inno-spec’s current projects, they have e.g., applications for sorting plastic and the need of increasing purity; as well as sortin fruits/vegetables. This is becoming more and more important.

Easy Engineering: What were the needs of the client?

INNO-SPEC: The clients must avoid claims or recalls of products. Most of these starts with using it for quality control. But also, for sorting plastics as a higher purity and a higher throughput and a higher value is required.

E.E: Why did the client choose your products / solutions?

INNO-SPEC: Our solution is an inline solution which works 24/7 and can control 100% optically without destroying or harming the tested sample. Further on we produce cameras specialized for industrial purposes in an acceptable price range.

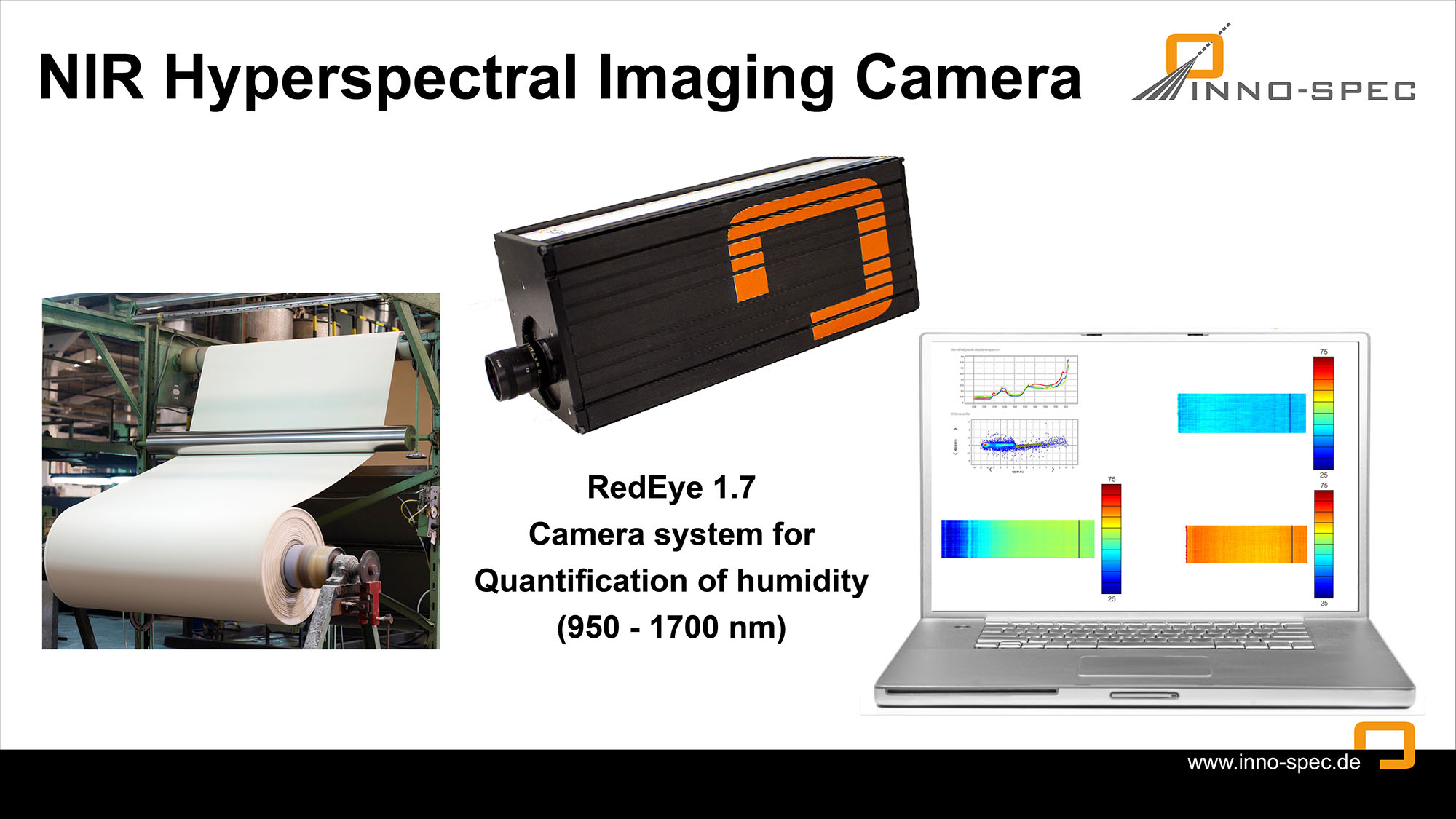

E.E: What products / solutions were used?

INNO-SPEC: Our customers use mostly our product portfolio around RedEye, the additional lighting and the software form our partner Luxflux.

E.E: Please describe how was the project implemented?

INNO-SPEC: Typical route to implementation:

- Feasibility study (lab).

- Extended feasibility tests, clearly defining all parameters such as thresholds, all occurring “ok” and “not ok” variations, interference factors. (This is crucial! Especially for natural products such as fruits and vegetables, a huge number of variations occur, but also for industrial products, the range of still acceptable parameters can be wide. Software based separation can only work if the software is properly working and taught what to accept and what to reject.) This can take place in the lab or in a pilot plant.

- Moving the solution to the final machine or plant, doing necessary adjustments, and iteratively optimizing the output by working on hardware (illumination, orientation) and software (data pre-processing and sorting algorithms).

E.E: Were there any products with special characteristics used?

INNO-SPEC: All our “standard” products have a huge potential of applications, which usually makes it unnecessary to customize them for a certain application. Customization happens on a small scale by e.g., adapting the field of view by choosing the proper lens + working distance, or optimizing illumination (direct or diffuse) for the surface characteristics of the inspected goods. Real customization happens in the software.

E.E: How did your products / solutions improve productivity for the client?

INNO-SPEC: Our technology makes certain steps in a process, such as a sorting or control step:

- in some cases, possible where before it simply could not be done;

- faster than it was before, using a different technology;

- more reliable than it was before, using a different technology;

- more widespread than it was before, by applying it to 100% of all goods instead of a spot check;

- more uniform than when done by humans.

It helps to avoid waste as it is a real-time method that directly can give feedback to adjust process parameters, so issues in the process line will show up right away.

E.E: How important was the project / projects for the client?

INNO-SPEC: For our main customers, it is the way they grow their market position and even become the market leader for certain applications. Even for smaller companies, they have an opportunity to beat big companies in the market.

E.E: What was the client feedback after implementation?

INNO-SPEC: One of our Chinese partners recently explained us that they were very thankful that we went with them through the whole process of implementation and that especially the support of running the technology and aftersales services with increasing the performance with working together in the project. This is the focus of inno-spec to support new partners to more success.

E.E: How did the solutions provided improve efficiency for the client?

INNO-SPEC: Usually first integrators have a higher risk or even investment to take, but in general they become the market leader for their special application!

E.E: Did the current situation made your company implement differently than usual?

INNO-SPEC: Yes, also Corona affects us. Because we are used to guide our clients through the process. That happens mostly personally on site of the customer. We work together closely. The availability of traveling is important for us. But we consider that this will be no problem anymore after the first half of 2021.

In addition, now is the best time to start new projects and to come out these crises with new applications. We could handle this situation very well with online support and, if necessary, with travel options inside.

E.E: What are your forecasts for the second half of 2021?

INNO-SPEC: We expect for 2021 a slowly growing business, because of investments it is still slow and difficult, but the market will become strong and HSI will increase the margins for new applications.

INNO-SPEC GMBH

Sigmundstr. 220 / B7, 90431 Nürnberg / Germany

+49 911 37 66 91 0