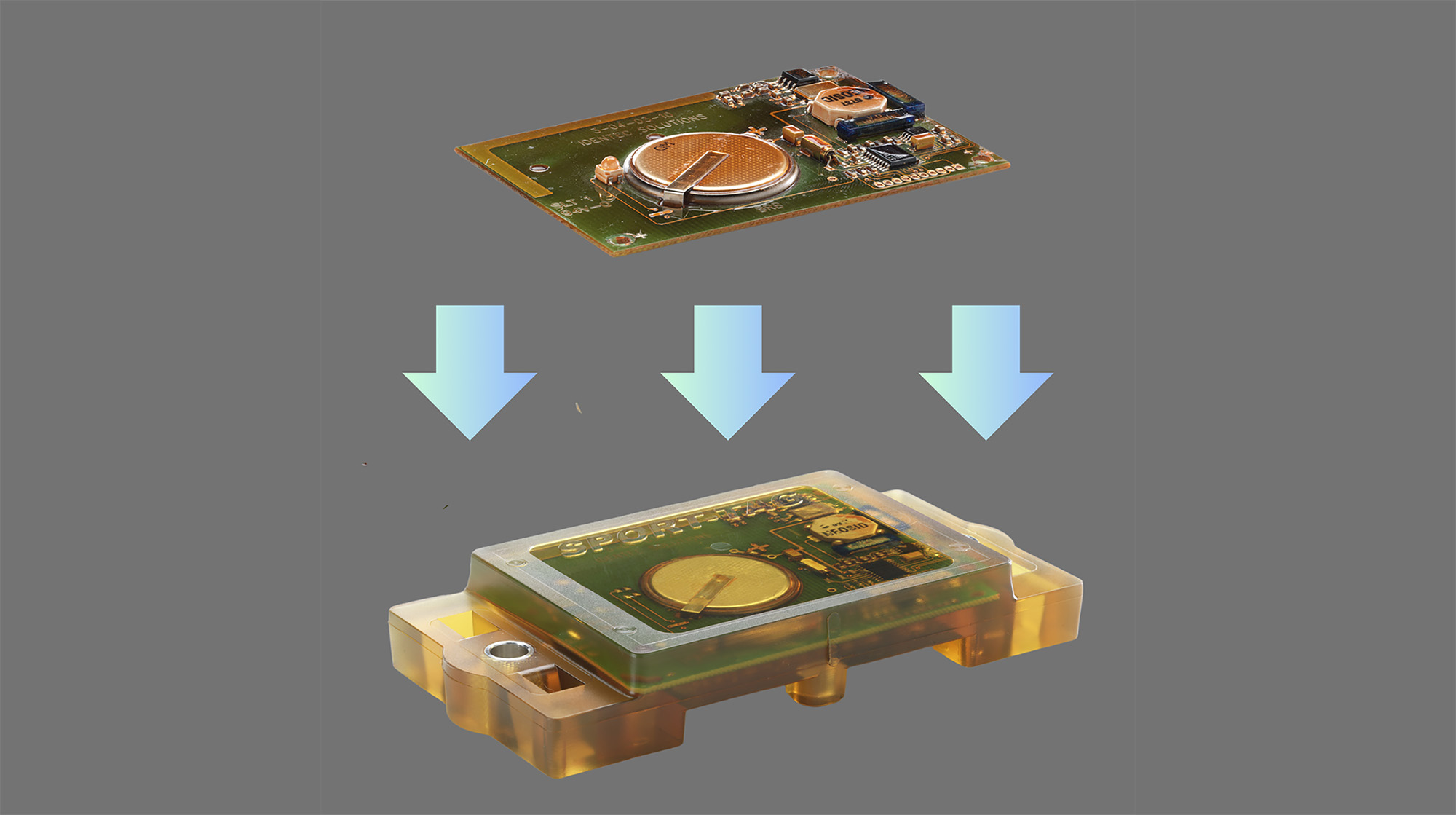

Cavist Manufacturing is a contract manufacturer located in Nevada, USA that specializes in overmolding and electronic encapsulation. Overmolding is an injection molding process where an electronic circuit board is encapsulated at low temperature/ low pressure using a protective material typically a polyamide or thermoplastic elastomer.

Since its inception in 1998, Cavist has focused on protecting electronics and electronic components like Sensors, MEMs, Capacitors etc. Cavist designed and built the globally renowned Moldman machines and sold the machines to customers in multiple sectors like medical, automotive, consumer electronics etc.In 2014, Cavist sold the machine building part of the business and focused on overmolding electronics as a service.

Today, Cavist is considered an industrial leader in overmolding electronics as Cavist has successfully overmolded millions of electronic circuit boards.

Interview with Peter Olisa, Head of Sales & Program Management at Cavist Manufacturing.

Easy Engineering: What are the main areas of activity of the company?

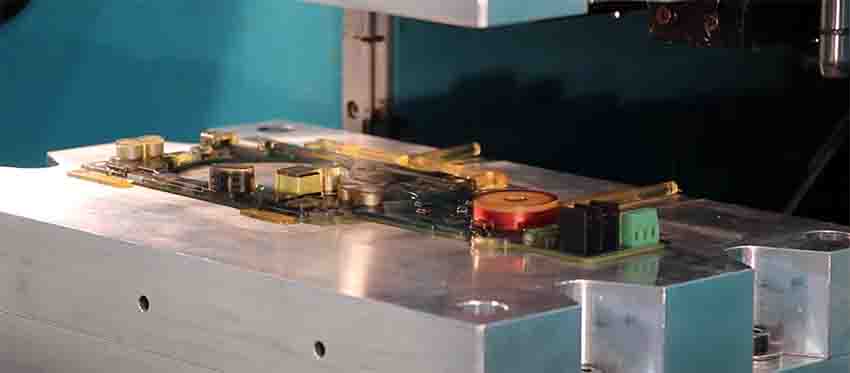

Peter Olisa: One of the major areas of activities for Cavist is DFM & Prototyping and qualification. Cavist provides DFM & prototyping services to customers looking to use overmolding as a packaging solution for their products. We provide feedback and recommendations that improve the overall manufacturability of the products. We create rapid prototype molds to produce samples that can be used for testing and feasibility studies. Once these samples pass testing, we work with customers to produce a production tool and create a molding process that guarantees high yield. If needed, we qualify the entire process to ensure conformity/compliance to quality and regulatory standards like ISO 9001, ISO 13485, and FDA.

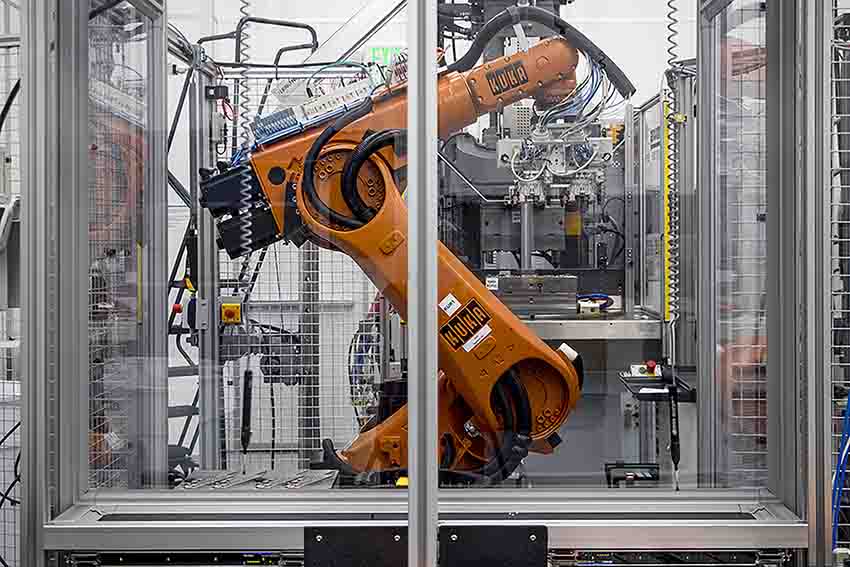

Another major area of activity for Cavist is low to high volume production. Cavist has the equipment and technical expertise to overmold products in high volume. Once products are qualified and released for production, Cavist has the capability to meet high volume demands including making millions of parts. Cavist can also provide other value-add services like soldering, laser marking, assembly, and full turnkey supply.

The last area of activity for Cavist is engineering services. Cavist work with customers to stand up high volume overmolding production lines at their facility.

E.E: What’s the news about new products/services?

P.O: Over the last 25 years, Cavist has consistently pushed the limits and explored new ways of overmolding electronics. Some relatively new technologies at Cavist include the overmolding of electronic boards using Thermoplastic elastomers (TPE), Thermoplastic Urethane (TPU), Epoxy Molding Compounds (EMCs). These materials improve the ruggedization of products making it possible to achieve higher levels of ingress protection, resistivity, electrical insulation, biocompatibility, sterilization, and thermal conductivity.

E.E: What are the ranges of products/services?

P.O: Some of the ranges of products include products in the medical device and medical manufacturing sector, automotive/EV sector, consumer electronics sector, Industrial equipment sector etc. In the medical device and medical manufacturing sector, Cavist has worked with customers to successfully overmold electronic devices like power modules, controller boards, Continuous Glucose Monitors (CGM), surgical instruments etc. In the automotive/EV sectors, Cavist has worked with customers to overmold Battery Management Boards, sensors, GPS trackers, cable harnesses, display controller boards etc. In other industries, Cavist has worked with customers to overmold products like industrial light nodes for bridges, body cameras for law enforcement, security USB keys etc.

E.E: What is the state of the market where you are currently active? What can you tell us about market trends?

P.O: We consider electronics encapsulation/protection as the market segment we are active in, and we have seen the market trend upward with demand increasing significantly. More companies are pushing for their products to have a robust packaging solution that protects the electronics from impact, dirt, moisture ingress etc. This has resulted in engineers exploring options of electronics encapsulation and protection. The popularly known methods include conformal coating, clamshell housing and epoxy potting. Nevertheless, overmolding is gaining notoriety in the industry as a preferred method for encapsulation. Overmolding protects electronic devices from moisture, vibration, and dirt. It is extremely cost effective to implement in comparison to other methods of encapsulation and it is easily scalable for high volume manufacturing.

E.E: What are the most innovative products/services marketed?

P.O: One of the most innovative overmolded products marketed is a CGM device for diabetics. This device helps diabetics take control of their health. The CGM device tracks blood glucose levels and alerts people when their levels are high or low.

E.E: What estimations do you have for the beginning of 2024?

P.O: Electronics are becoming increasingly needed in all industries and in more and more aspects of our personal lives. This trend is only going to continue exponentially. We expect 2024 to be filled with electronic innovations that continue to change and impact our lives. Behind the scenes, Cavist will continue to be the subject matter experts in electronic encapsulation, providing companies with packaging solutions that protect electronics from harsh environments.