CETI is a European technical private center for applied research and innovation for a sustainable textile industry to find more natural, sustainable and ecological solutions. CETI has been innovating for the past 10 years for leading technical textile and professional apparel brands, as well as sports, fashion and luxury textile.

The company responds to this market through several platforms of digitalization, innovative design, prototyping (virtual and physical), industrial transfer and training. The missions of the CETI are: 1- to promote and accelerate innovation in the field of textiles, 2- to propose advanced equipment needed for prototyping and 3- to collaborate with the economic and research players to enhance the competitiveness and sustainability of the textile field.

Interview with Priscilla Arnould, R&D Project Manager in the Polymer Business Unit & Javier Vera Sorroche, Director of the Polymer Business Unit at CETI.

Easy Engineering: What are the main areas of activity of the company?

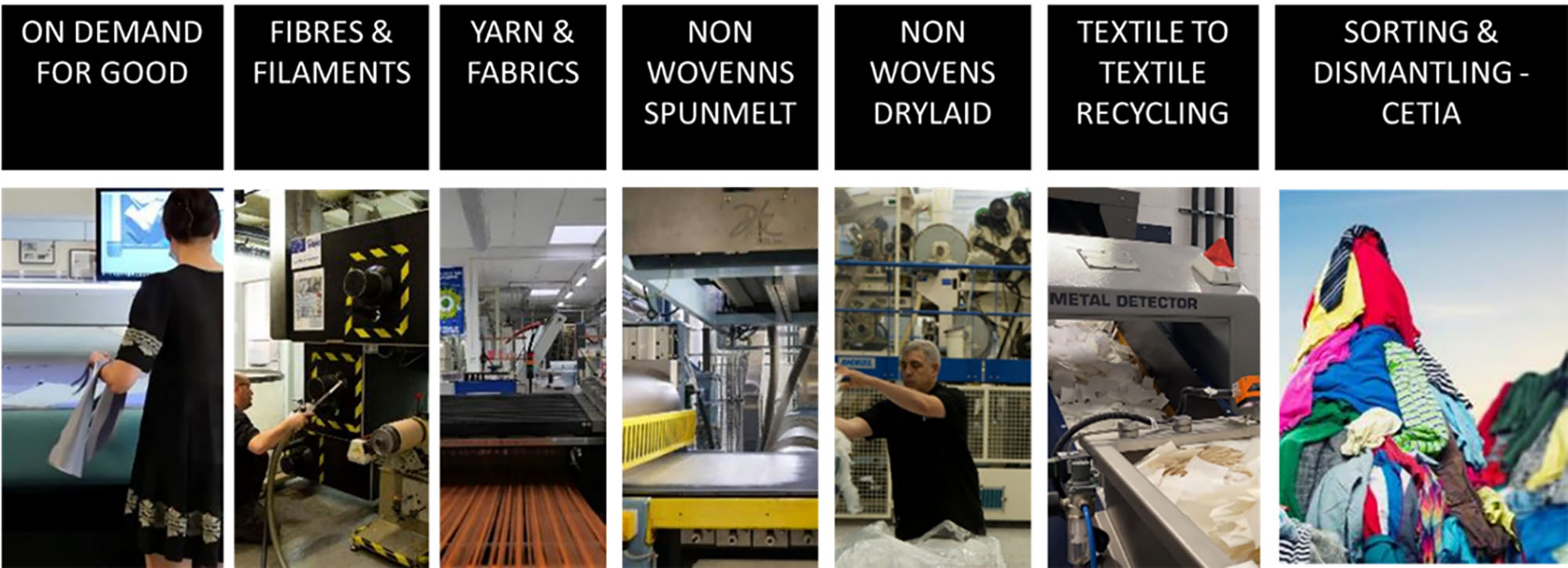

Priscilla Arnould & Javier Vera Sorroche: CETI areas of expertise are: digitalization, recycling and formulation of materials which make CETI to maintain a leading position through innovative textile circular solutions and superior customer service in France and worldwide. To provide textile to textile solutions, CETI has implemented world-class mechanical and thermomechanical recycling approaches for natural and synthetic fibers which are bringing new filaments, yarns, fabrics and nonwovens into the Textile market. In the south of France, CETI and ESTIA have created CETIA, a pioneer platform dedicated to the automated sorting and dismantling of end-of-life or unsold textile and footwear items

E.E: What’s the news about new products?

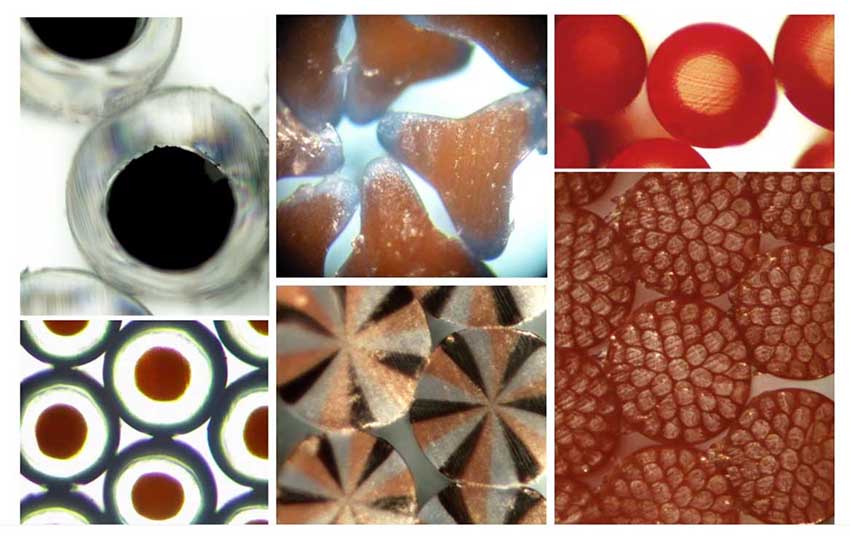

P.A & J.V.S: CETI is one of the main actors in the H2020 project SCIRT which is a unique collaboration between 18 industries and research institutes such as Decathlon and Petit Bateau. The aim of this project is to demonstrate an entire textile-to-textile recycling system for discarded clothing or post-consumer textiles. In this European project, CETI is currently developing fiber to fiber solutions at which multicomponent melt spinning provides an opportunity to merge two or more distinct polymers, each with unique properties, into single fibers that are planned to be used as one of the mayor components in Sport & Swimwear applications.

E.E: What are the ranges of products?

P.A & J.V.S: CETI works with a wide range of natural, artificial and synthetic fibers such as cotton, viscose, cellulose, and thermoplastic polymers coming from conventional materials -PP, PA, PET- to biobased and biodegradable raw materials such as PLA, PHA and STARCH. CETI can offer consumer solutions to Hygiene, Wipes, Filtration, Geosynthetics and Construction, among others.

E.E: At what stage is the market where you are currently active?

P.A & J.V.S: CETI has been engaged for the past 10 years in the development of technical textiles for sport, mode, luxury but also for hygiene, wipes and filtration where the markets have risen. CETI’s Technology Readiness Levels (TRL) ranges from 4 to 9 so CETI can support customers from prototyping up to manufacturing through co-developed engineering approaches and industrial transfer. Currently, CETI is exploring and bringing new solutions for medical, aerospace, and transport applications.

E.E: What can you tell us about market trends?

P.A & J.V.S: In the last years, markets of wipes, absorbent hygiene, medical and construction are growing fast in terms of sales and in volume. However, a slow down was observed in transportation field and apparel for example. In addition to that, our customers are eager to find new sustainable and alternatives solutions that can replace fossil raw materials.

E.E: What are the most innovative products marketed?

P.A & J.V.S: CETI is deeply involved in sustainable approaches and open or closed textile recycling loops for post-production and post-consumer products which can minimize waste, conserve resources and reduce environmental impacts in the European market. For example, the main goal of SCIRT is to create new collections of garments with at least 50% of recycled material through different way of recycling: enzymatic, chemical, mechanical, and thermomechanical.

E.E: What estimations do you have for the rest of 2023?

P.A & J.V.S: To address the environmental concerns within the textile industry, CETI is enhancing its existing mechanical and thermomechanical solutions for postconsumer textile wastes. Moreover, CETI is constructing state of the art facilities for chemical recycling, which are planned to be fully operational in 2024. This new platform is expected to be at the forefront in the field of plant and protein-based fibers recycling.