CGM CIGIEMME is one of the leading manufacturers of nondestructive testing (NDT) systems with a worldwide network covering over 30 countries.

Decades ago, CGM was among the first to grasp the growing importance of quality control in the industrial sector, and since then the company has established itself as a leader and a provider of cutting-edge solutions for quality assurance in various industries. The company’s major markets include oil & gas / steelmaking, aerospace, railway and automotive industry.

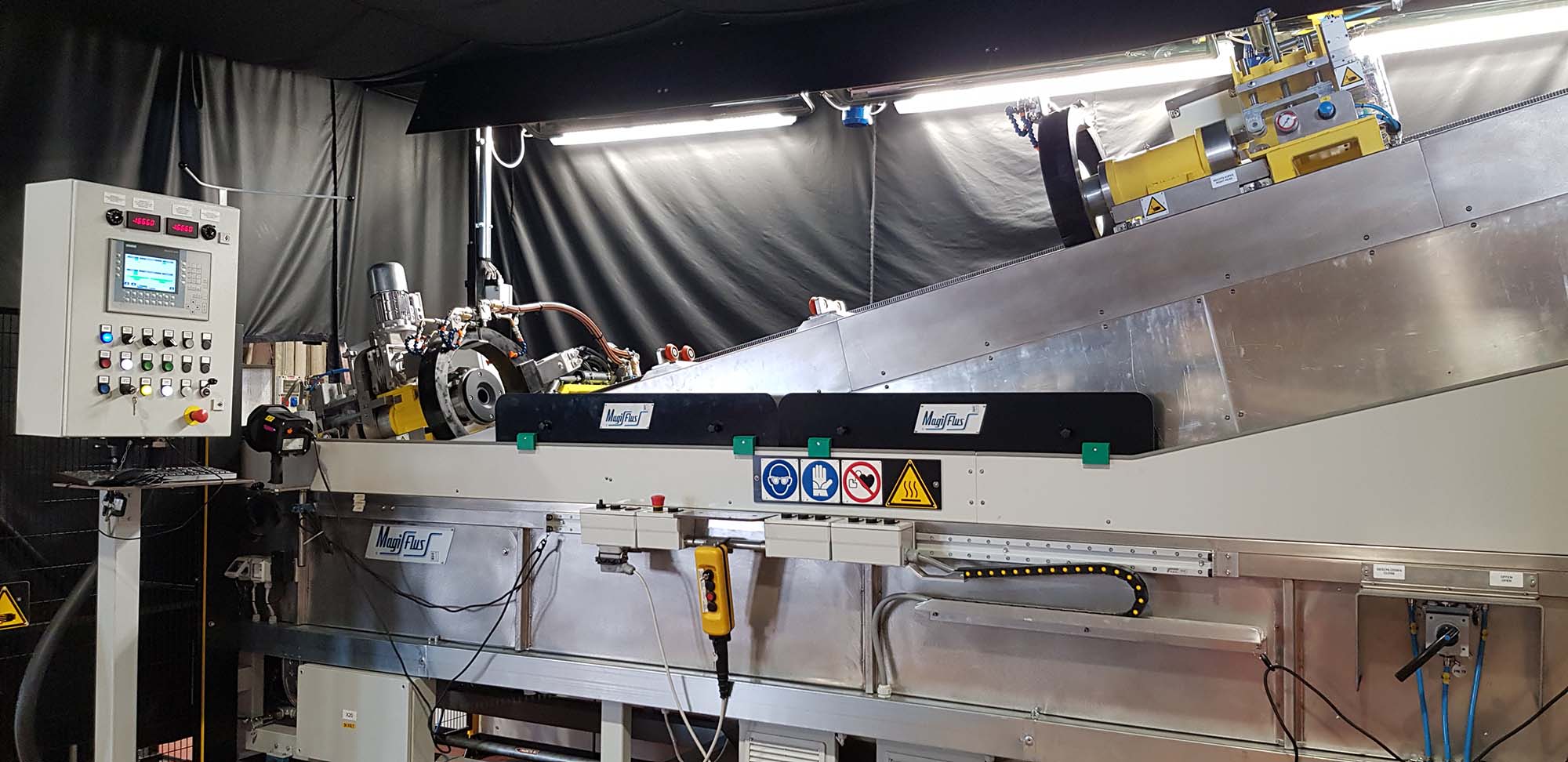

CGM has a long history of offering a wide range of reliable and robust Magnetic Particle (MT) and Liquid Penetrant (PT) inspection equipment – from small portable systems to highly customized in-line automated systems – for the inspection of critical components by largest steelmaking and railway plants, as well as major aerospace and automotive components manufacturers all around the world, who value CGM systems for their robustness, flexibility in design, and technological excellence.

From the very beginning CGM has been customizing all its systems to meet the standards and specific application needs of its customers and end users, helping them achieve their operational goals through improving overall efficiency, safety and quality of the operations.

Interview with Michele Burei, Head of Global Sales and Level III MT&PT at CGM.

What are the main areas of activity of the company?

Michele Burei: CGM’s core competence is the design and manufacture of highly customized Magnetic Particle Inspection (MT) systems and Liquid Penetrant Inspection (PT) systems. The design of each system is tailored to the geometry and specific characteristics of the component to be processed.

The propensity to constantly search for innovative solutions is one of the keys to CGM long and successful history. For these reasons, CGM has been also making substantial investments in R&D activities aimed at reducing the environmental impact, increasing the safety of the workplace environment, constantly improving the ergonomics of the systems being designed and manufactured, developing HMI solutions that ensure a user-friendly experience, as well as designing systems to meet the most rigorous audit requirements of the external certifying bodies.

All design, manufacturing and R&D activities are carried out entirely in Italy, with after-sales service available globally.

What’s the news about new products?

M.B: The latest achievement in the magnetic particle inspection (MT) field is an automated system with the automatic creation of an inspection report for each inspected component, containing photos of possible indications/defects that need to be stored. This allows for full traceability of the inspection process and, thus, dramatically improves the inspection quality.

Another important milestone – this time in penetrant inspection method – is CGM’s development of fully automated PT lines for aerospace and automotive industries, which help customers increased throughput while significantly reducing costs, as well as improve production quality and efficiency by minimizing human error.

What are the ranges of products?

M.B: In the field of Magnetic Particle Inspection, CGM designs and manufactures both standard equipment, as well as special execution – both standalone and in-line – automated systems.

The portfolio of the projects delivered in the field of Penetrant Testing includes manual systems, semi-automated and fully automated PT systems, as well as robotized fully automated PT lines for various penetrant sensitivity levels with electrostatic application.

In addition to MT and PT systems, CGM offers the whole range of consumable products, tools, accessories and instruments used in the MT and PT fields.

At what stage is the market where you are currently active?

M.B: CGM is active in the field of quality control. Compared to past years, this sector is gaining more and more importance within production processes. Components that in the past were not inspected at all, or were inspected on a random basis, are now inspected at 100% of production. Quality control is now seen as a resource and not a problem, therefore justifying investments in automated equipment and new technologies. The market appears to be growing and is finally getting past the conservatism that has characterized this sector for years.

What can you tell us about market trends?

M.B: As with any production process, quality control is also subject to classic market laws where any given company’s goal is to produce to the maximum possible extent while reducing labor costs and minimizing possible human errors. This has led to the development of new technologies applicable to two nondestructive testing methods such as magnetic particle and liquid penetrant inspection, where the operator still plays a fundamental role within the process. The market trends are therefore: constant innovation, automation, and cost reduction.

What are the most innovative products marketed?

M.B: Among the most advanced products marketed by CGM are the magnetic particle inspection systems with remote inspection, which allow to inspect the components outside of the inspection booth, thus considerably increasing the overall operator’s safety.

Another most recent and important novelty applied is the application of Automatic Defect Recognition (ADR) technique. CGM has been working on this kind of software for at least 20 years, but only recently – with the help of artificial intelligence – has it become possible to obtain excellent results applicable to the industrial sectors. CGM’s team is currently working on various ADR software applications for magnetic particle inspection: reducing human error in special processes to the greatest possible extent remains a major priority and focus of all ongoing R&D initiatives.

What estimations do you have for 2024?

M.B: These last months of 2023 are already defining our 2024. We have been expanding to new markets where in the past we had only been present with a very few projects and where we are now consolidating our presence. The major markets for CGM continue to be aerospace, railways, oil & gas and automotive. Our 65 years of experience, together with over 70% of the systems manufactured being shipped worldwide, allow us to face any possible challenge with awareness, energy and resourcefulness.