Clip-Lok SimPak is a Danish-based company with a global presence through their network of partners, specializing in producing professional packaging solutions for a wide range of industries, including automotive, industrial engineering, robotics, defense, healthcare, energy, and more.

Interview with Anders Lassen, CEO & Founder of Clip-Lok SimPak.

Easy Engineering: What are the main areas of activity of the company?

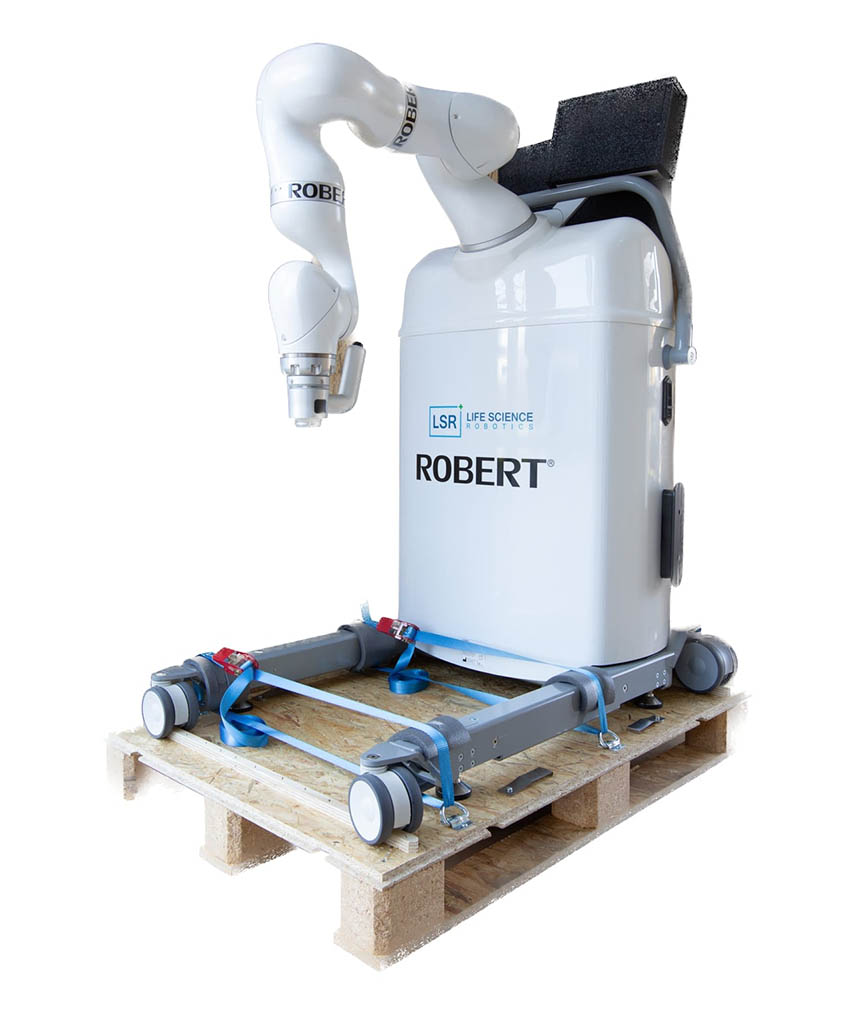

Anders Lassen: At Clip-Lok SimPak, we are known for creating customized packaging solutions tailored to the specific needs of our clients. For instance, we’ve worked on packaging solutions for the robotic industry, successfully developing packaging for healthcare robots. Additionally, we’ve provided packaging for the defense sector, including Remote Weapon Stations (RWS), and even transport boxes for UN-approved lithium batteries for buses with a gross weight of up to 739kg.

Moreover, at Clip-Lok SimPak we produce steel racks for the automotive industry, where we specialize in providing customized metal packaging designed to meet the unique requirements of this dynamic sector.

E.E: What’s the news about new products?

A.L: At Clip-Lok SimPak, we consistently innovate by designing and developing cutting-edge packaging solutions tailored for the transport of lithium batteries and their components, ensuring our clients receive the latest in safe, efficient, and sustainable packaging solutions.

E.E: At what stage is the market where you are currently active?

A.L: In the markets where we currently operate, significant growth characterizes our key focus areas. Robotics, driven by labor force shortages, are experiencing notable expansion. We actively contribute to the ongoing transformation within the automotive industry, transitioning from fossil fuels to electric vehicles. The defense sector is growing, influenced by the unfortunate war in Ukraine. Additionally, the alternative energy sector is on the rise, responding to increasing environmental concerns.

E.E: What can you tell us about market trends?

A.L: The markets we operate in are dynamic and evolving. For instance, the rise of automation and robotics is already underway. According to a report by McKinsey, in the next five years, the average investment into automation is projected to be 25% of capital investment in various industries. This trend is driving a need for very specific packaging solutions, not only for machinery robots but also for nursing robots, heavy-duty drones and many others.

Another significant trend is the energy sector’s transition from fossil fuels to sustainable energy sources. We provide customized packaging for components primarily for windmills, although we also see a growth possibility in other types of alternative energy. Overall, sustainability is a key trend across all industries, with more businesses seeking eco-friendly suppliers.

E.E: What are the ranges of products?

A.L: Our product range includes flat-packable, reusable packaging, which is not only cost-effective but also has a low environmental impact. We specialize in tailor-made, bespoke packaging solutions, which can significantly reduce transport costs throughout the entire value chain, promote sustainability, and minimize the use of raw materials. Our packaging is designed for easy assembly and disassembly, making it ideal for large equipment and in-house packaging needs. It’s worth noting that our packaging is assembled with clips, without the use of nails or screws, making it easy to recycle and environmentally friendly. We also leverage digital technology to design packaging, calculate ROI, and assess the environmental impact, ensuring our customers make well-informed decisions.

E.E: What are the most innovative products marketed?

A.L: Our innovation lies in the customized packaging solutions we provide. Our QIK-clip technology, available in both steel and plastic variants, allows for easy assembly and disassembly without the need for tools. This not only saves time but also contributes to sustainability by reducing waste. Additionally, our extensive use of digital technology in designing packaging and calculating environmental impact sets us apart. We take pride in being a reliable and stable supplier with over 35 years of experience in the industry.

E.E: What estimations do you have for the rest of 2023?

A.L: While I can’t provide specific financial projections, we are optimistic about our growth prospects for the remainder of 2023. We believe that our commitment to sustainability, innovative packaging solutions, and our global network will continue to position us as a preferred partner for businesses across various industries. Our focus remains on delivering packaging solutions that not only meet our clients’ needs but also contribute to reducing environmental impact, in line with global sustainability goals.