Schöck is a manufacturer and supplier of innovative building materials and services that support efficient construction: The family-owned company was founded in 1962 in Germany and has since grown to a global company with over 1,100 employees and subsidiaries in 12 countries throughout Europe and North America. Through partners and representatives, Schöck products reach customers in more than 40 markets worldwide.

Company history

In the early 60s the German economic miracle was still in full swing; the economy was booming and housing construction was expanding. The ideal time to set up a company. In 1965, Eberhard Schöck even spoke of a hyper-boom with regard to the construction activity of those years. He founded a small construction company in 1962.

In the beginning he specialized in the construction of basements for prefabricated houses. His credo: “Making building modern!”.

The Schöck Company has been very successful from the beginning. Eberhard Schöck know how to steer his company in the right direction, and his wife and employees supported him very well. He skillfully built up several pillars to make his venture future- and crisis-proof.

Although the construction team initially started with building basements for prefabricated houses, Schöck set up an industrial production of basement windows and light wells in parallel. The company also manufactured concrete elements.

The breakthrough came some time later with the famous Isokorb, which has remained a bestseller to this day. As the company grew, other locations were added to Baden-Baden.

Product history Isokorb®

During a skiing holiday in 1979, Eberhard Schöck came across a large holiday home with numerous uninsulated balconies. This led to damp walls and mould formation indoors. While still on holiday, he started developing initial ideas and sketched for solving this weak point in the building in terms of building physics and structural design. This marks the birth of the Isokorb.

In 1983, the first Isokorb Type M was introduced to the market by presenting at DEUBAU in Essen and SWISSBAU in Basel. The trade fair visitors were very interested in the product.

Going forward in 2002 the previous stainless steel thrust bearing of the Isokorb was replaced by an innovative thrust bearing with a plastic sheathing and micro-steel fibre reinforced high-performance fine concrete, leading to a significant improvement in the thermal insulation performance of the Isokorb.

In 2008 the Schöck Isokorb KXT was developed. A load bearing thermal insulation element with a 120mm insulation thickness.

In response to the high demand for building project in existing contexts, Schöck launched a new type of thermal separation for cantilevered or supported balcony structures of existing buildings. The Isokorb R is retrofitted to replace or supplement balconies in the event of renovation.

The last type of Isokorb Type CXT now incorporates tension rods made of the pioneering glass fibre reinforcement Combar. An additional 120mm layer of Neopor ensures optimum thermal insulation. Ans the thrust bearing made of micro-steel fibre-reinforced high-performance fine concrete also contributes to an energy-efficient product for the balcony. With its improved CO2 balance, the product also contributes to sustainable building.

Schöck Isokorb celebrates its 40th anniversary in April 2023.

Product history – other products

In 1985, Schöck launches another pioneering product on the market: the Tronsole is an impact sound insulation element, ensuring safe impact sound protection and acoustic bridge-free design for stairs for an added quality of life.

Combar is a reinforcing bar developed by Schöck in 1997: It is made of glass fibre composite material, consisting of a combination of glass fibres and resin as corrosion-free reinforcement.

The Isolink is a thermal-bridge-free fastening system for ventilated facades. The façade fastening consists of Combar and a stainless steel connection thread. (2018)

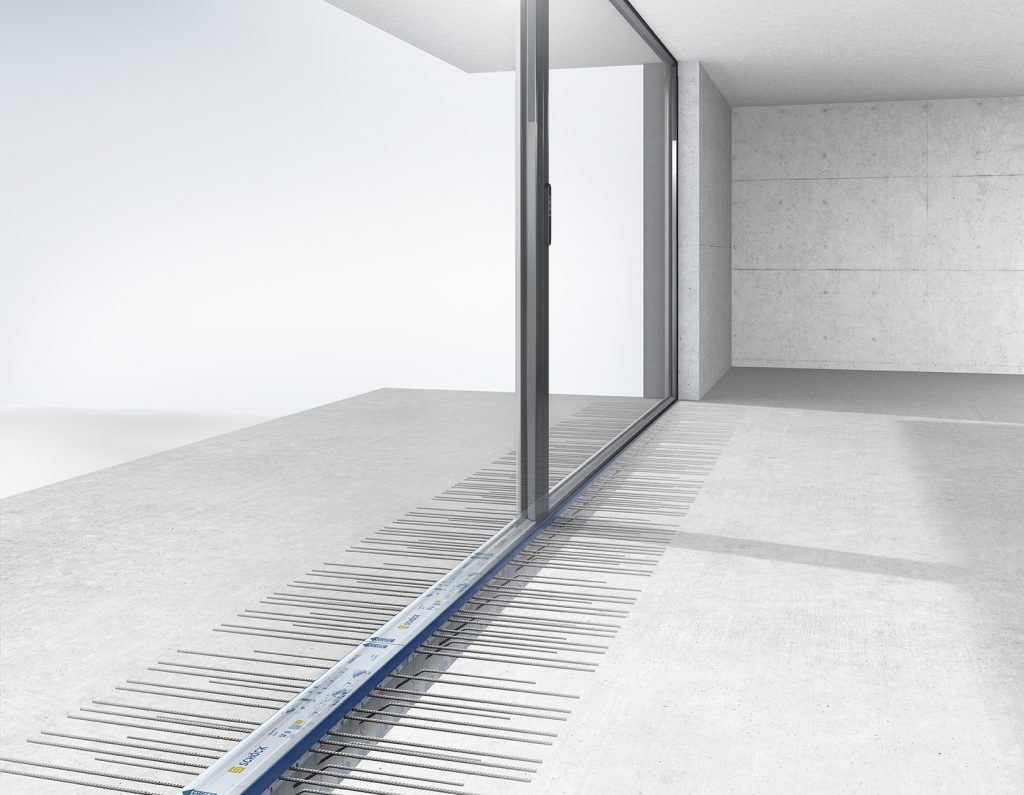

As a specialist in load-bearing thermal insulation, Schöck solves the last major thermal bridge on buildings with a world first: Schöck Sconnex insulates reinforced concrete walls and columns directly and permanently. This makes it possible to reduce thermal bridges and to design a continuous thermal insulation layer without any interruption.