COMPREDICT is a deep-tech startup based in Darmstadt/Germany. They provide the automotive and mobility industries with software algorithms and analytics that enable large-scale exploitation of in-vehicle data, using machine learning (ML) and artificial intelligence (AI).

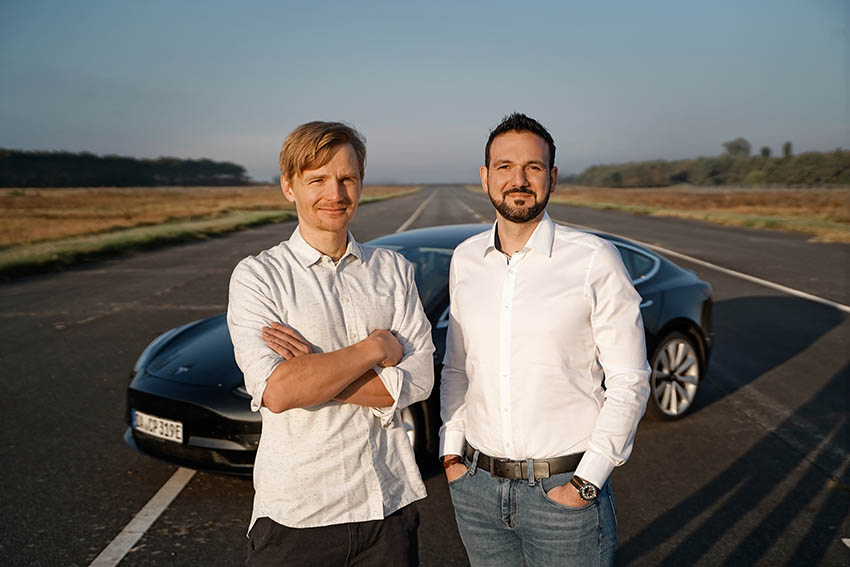

Interview with Dr.-Ing. Stéphane Foulard/Co-founder and Managing Director at COMPREDICT.

Easy Engineering: A brief description of the company and its activities.

Stéphane Foulard: Together with my co-founder, Dr.-Ing. Rafael Fietzek, we founded COMPREDICT in 2016 after our PhD studies at TU Darmstadt. During our research work, Rafael and I recognized the high optimization potential that still remains unused in vehicle engineering. Efficient use of in-vehicle data would allow cost savings and emission reductions for manufacturers, fleet operators and consumers: through precisely dimensioned components, longer durability, predictive maintenance and optimized fleet management until resale.

However, when currently talking to automotive industry players, it seems that the adoption of methodologies to make use of vehicle data is mostly still at an early stage. In many cases, large amounts of data are generated, but then hardly used. There is a demand for clear, powerful, and privacy-compliant tools that can be used across departments and easily rolled out.

This is where we step in: at COMPREDICT, we develop various virtual sensors that enable such an evaluation of vehicle data at large scale. We are currently 25 employees in three teams: vehicle experts, experts in IT and machine learning, and business development.

E.E: What are the main areas of activity of the company?

S.F: Our first area of activity right since 2016 was automotive R&D. I have written his PhD thesis on how to use in-vehicle data for improved vehicle reliability and durability calculations. Today, vehicle components are often over-designed, in order to be “on the safe side” so that they do not break over a whole vehicle lifetime, even for the most demanding 1% of the drivers. But this does not make sense for the 99% of other drivers: over-design increases weight, cost, fuel consumption and CO2 emissions. Our target is to contribute to CO2 reduction with precise determination of load profiles from prototype vehicles or series cars, so that manufacturers can reduce component weight, cost and also save development time.

The second area of activity which we further developed this year is condition monitoring of series vehicles. We either cooperate with companies providing telematics solutions to fleet managers and consumers, or with fleet operators directly. Our virtual sensors enhance existing fleet management solutions with precise data for predictive maintenance and fleet optimization. We observe a clear market demand for tools to reduce maintenance cost and to increase fleet efficiency.

Very recently, we have also been contacted by insurance companies regarding driving profiles and the remaining value of vehicles.

E.E: What’s the news about new products?

S.F: It has got to do with the industry shift to hybrid electric vehicles (HEV/PHEV) and battery electric vehicles (BEV). Electrified cars behave differently and are driven differently from conventional vehicles.

We are now working on a project with an European manufacturer, where we calculate the impact of a new electrified powertrain on their durability requirements. We even deployed our virtual sensors to a fleet of prototype vehicles in order to gather reliability data over large distance in short time, with software-based sensors.

Besides, we are involved in a project called De4LoRa (Double e-drive for Long Range), where a consortium led by Vitesco Technologies and TU Darmstadt is developing an innovative electric powertrain with a specific architecture to reduce the cost of electric vehicles for consumers while still providing sufficient range autonomy.

Still in electrification, we have found out that our virtual sensor for vehicle mass, that is now available „off the shelf”, is of major interest for precise range estimation of battery electric vehicles.

E.E: What are the ranges of virtual sensors you provide in automotive industry?

S.F: In the market segment of telematics solutions and fleet management, we offer various virtual sensors for vehicle mass, battery condition monitoring, brake pad wear, brake anomaly and tire tread depth. They are ready to be deployed without training of the algorithms on each vehicle. Integration into existing fleet management tool takes place through flexible REST API and SDK. Our virtual sensors can provide a clear competitive advantage to fleets through improved fleet efficiency and reduced operating costs.

In the market segment of automotive vehicle development, we provide specific virtual sensors that measure component fatigue and durability, wheel forces and torques, steering forces or high voltage battery aging. Our virtual sensors help to reduce R&D times and costs, and to increase product quality. They allow scaling of very expensive test campaigns to larger number of prototype vehicles and longer mileage, without any risk of damaging sensitive laboratory equipment.

E.E: How does a virtual vehicle sensor work?

S.F: Virtual sensors are software-based. They make use of various existing sensors in a vehicle, like for example a temperature sensor or a speed sensor. Through sensor fusion they calculate a target signal or target information that would be otherwise too costly or too complicated to measure.

E.E: At what stage is the market for virtual car sensor technology?

S.F: Data science is a rather young discipline in automotive industry. Currently, data volumes generated by connected vehicles increase, while manufacturers still lack safe and convenient tools for large-scale exploitation of these in-car data. We offer a mature solution to a market that is now becoming aware of the value in their data – a domain where considerable market growth is expected in the upcoming years. Manufacturers and fleet managers estimate that big data analytics is the next big thing to drive innovation.

E.E: What can you tell us about market trends?

S.F: You have to consider that 50% of newly registered vehicles worldwide are already somehow connected today. By 2030, 95% of new cars worldwide could even be connected.

Forbes predicted that “[…] the market for data from cars in motion will become five times bigger than the market for cars themselves.” (Peter Cohan, Forbes.com, August 18, 2021).

Whatever the exact figures will be, industry experts agree on market growth: the market size for in-car data will become a multiple of the market size for cars.

E.E: What are your most innovative virtual sensors?

S.F: Virtual sensors are not new: their concept dates back to 1990. Today, they are getting more and more adopted in other applications like manufacturing, supply chain, IoT or generally speaking in connected cyber-physical systems. Autonomous cars use sensor fusion to merge information received from various sensors like cameras, radar and LIDAR technology.

What distinguishes us from other providers of AI-based algorithms and analytics are our deep vehicle knowledge and our patented algorithms. We provide, for example, a unique virtual sensor vehicle mass. It is capable to monitor the loaded mass throughout a working day with a precision of +/-5%, and it works off the shelf with built-in automatic algorithm training for each car. When you consider that the driving range of an electric delivery vehicle depends heavily on the current mass, which changes all over the day, the value of our innovation for efficient charging management becomes obvious.

E.E: What estimations do you have for 2022?

S.F: We are right now scaling up and working on large vehicle fleets with several automakers. As well, we are running our third financing round (Series A) to support our growth. Next year, we plan to expand to Asia and North America.

Read more about COMPREDICT’s vehicle sensor insights.