Easy Engineering: How do you see sustainability and what are your efforts in this direction?

FALCOR: Our business has sustainability as one of its founding values. By proposing solutions for compaction, we automatically propose solutions to sort and recover waste and to reduce the number of trips on trucks to transport it. The use of our compacting balers can reduce the environmental impact of a company, reducing CO2 emissions and transforming waste into material for new productions.

In 2020 we created Saclò (https://www.saclo.it/en/) a line of dustbins for separate waste collection based on the innovative continuous bag system. The different models, the 6 colors available for refills and refills in biodegradable material help our customers to manage the waste sorting in the company in the best possible way.

By adopting waste balers and Saclò dustbins a company can achieve remarkable results in the differentiation of waste. This translates into a very high percentage of material that does not end up in landfills, but is recycled.

The continuous bag system also guarantees a plastic saving of 70% compared to the use of traditional waste bags (https://www.saclo.it/vantaggi/ ) . With the use of traditional bags, the operator who has the task of changing the waste bags in the company will collect full bags but also bags that are only partially used with a significant waste of plastic.

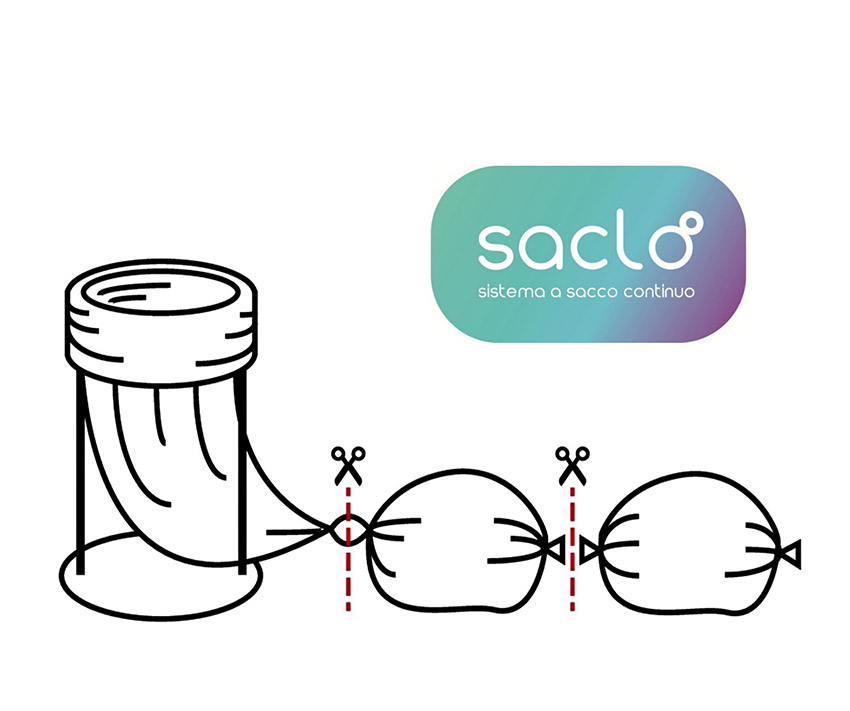

With Saclò this does not happen: the continuous bag is a long plastic tube open at the ends and wound around itself that is unrolled downwards and closed at the base. When he has to collect the waste bags, the operator compresses the bag with two hands to reduce the volume of the waste (without touching the waste), closes the bag above the waste and with a band closes what will become the base of the new one. sack. In this way there is no waste of plastic. The bag is cut where needed.

E.E: Tell us about the sustainable solutions that you offer (if any).

FALCOR: Our line of Saclò baskets and refills (https://www.saclo.it/en/products/) is based on an innovative system called “continuous bag”. Thanks to a single folded bag, up to 110 meters long, to be placed inside our dustbins, the collection of the bags is greatly facilitated and up to 70% of plastic is saved compared to the use of traditional bags. The sack is always cut when needed: half-empty sacks are never thrown away.

The purchase of waste balers and compactors has, among the many advantages, greater sustainability of the company that uses them, reducing their environmental impact.

Attention to the environment has led our sales partners to develop increasingly sustainable solutions. For example the vertical balers have low noise impact, and we can offer the bins compactors in the version with photovoltaic unit that does not require an electrical connection.

E.E: Do you offer solutions for reinvigorating old equipment with new solutions?

FALCOR: We offer the possibility of carrying out a technological update on vertical and horizontal compactors that do not have it. Using the BRA-IN Link system, developed by Bramidan, even the oldest compactors can be interconnected and monitored remotely. The possibility of this update ensures that the machines do not have to be changed (https://www.falcorpresse.it/tecnologia-40-per-la-compattazione/).

E.E: Tell us about sustainability in production & distribution.

FALCOR: Our Saclò continuous bags are made up of 3 thin layers of coextruded polyethylene. This makes them thinner than traditional bags, the thickness is in fact between 20 and 27 microns, but still very resistant. Less plastic is required to produce continuous bags than normal bags.

Our partners are also attentive to environmental issues. For example, Bramidan A/S has recently invested in a new pre-treatment and robotic powder coating plant which results in the absence of organic solvents for the environment and a 90% reduction in water consumption. The production of Agu Direkt GmbH products can be considered to have a practically neutral environmental impact: they have adopted a photovoltaic system that provides the electricity needed for production and the plant is heated with geothermal energy.

E.E: How do you promote this clean culture in your company?

FALCOR: In the company we do separate collection using Saclò dustbins and refills (https://www.saclo.it/sacco-continuo) in all company environments and we compact plastic and cardboard to reduce the number of collector withdrawals, sending only a small part of the waste we produce to landfill.

E.E: Tell us about preserving resources and driving circularity.

FALCOR: Production waste or packaging waste such as cardboard, plastic film, polystyrene, wood can become raw materials for new productions. Differentiating and compacting are the basis for the recovery of materials.

Falcor promotes the recovery of waste material with particular attention to polystyrene. Polystyrene is a material that can be recycled indefinitely, producing new polystyrene. Investing in a Runi press that reduces polystyrene into high density briquettes gives companies the opportunity to resell it.

As an Authorized Waste Broker, we have the opportunity to assist companies in this step as well. Once the polystyrene has been compacted, we can buy it and sell it to recovery plants.

E.E: How do you drive focus on sustainability of operations?

FALCOR: As we have already had the opportunity to explain, promoting the purchase of waste balers and compactors and our Saclò products translates directly into the promotion of sustainable solutions for companies.

Surely the theme of sustainability is one of the central themes that we try to communicate through the channels we have available, starting from our website and through our social media. We are developing, and will soon be online, a new section on our website that will address environmental issues in correlation with the use of our products.

E.E: Tell us about sustainable energy solutions used.

FALCOR: As regards our company headquarters, we have decided to install a photovoltaic system in order to exploit a renewable source and reduce our emissions.

E.E: How do you see sustainability in the future?

FALCOR: All our actions must become sustainable: it is no longer possible to design, produce, invest without thinking about the resulting environmental impact. Choosing more sustainable products or products that reduce the environmental impact is essential.

Web site: https://www.falcorpresse.it/

Linkedin: https://www.linkedin.com/company/falcor-srl

https://www.linkedin.com/company/sacl%C3%B2

Facebook: https://www.facebook.com/falcorpresse/

https://www.facebook.com/SaccoContinuoSaclo

YouTube: https://www.youtube.com/channel/UCxjO8QgNsJNs7uG1M-7v6GQ