AMP Robotics applies AI-powered automation to economically and sustainably improve the global recycling system. The company’s proprietary AI precisely identifies recyclables by color, size, shape, opacity, consumer brand, and more. The technology recognizes and recovers recyclables so these materials may serve another productive life in the economy.

Easy Engineering: Which are the most futuristic products / solutions from your portfolio?

AMP Robotics: AMP Vortex is the waste and recycling industry’s first artificial intelligence (AI)-powered automation system for plastic film removal and recovery. Vortex reliably and consistently identifies film and flexible objects, then uses an automated vacuum tube to capture and remove the material, depositing it in a configurable location. The recycling industry lacks infrastructure for the identification and separation of film and flexible packaging; these materials jam equipment that’s not designed to handle it. Even 2 to 3 percent film in recycling facility streams can be unmanageable to remove manually, often damaging equipment, necessitating downtime, and hindering recovery of recyclables. Film contamination degrades bale purity, leading to revenue loss or the need for additional post-processing downstream.

Because film is complicated and expensive to reprocess into raw materials, end markets for film have been limited. While film has been almost uniformly single-use, major brands continue to make commitments to use more recycled content in their products, and several states have adopted laws aimed at ramping up the use of post-consumer resin in plastic products and packaging. AMP is developing Vortex to recover film for baling and selling—executing on a vision to address the persistent contamination challenge and to stimulate markets

E.E: Tell us about product innovation and how does it impact the future?

AMP Robotics: AMP’s technology aims to tackle the challenge of managing materials more sustainably, shifting the economics of recycling. Plastics, metals, and paper all have real value. The problem is that the cost of sorting erodes that value. By reducing the cost of sorting, the margin that can be extracted on all those materials increases. In addition to decreasing the cost per pick in primary or secondary sorting environments, AMP’s technology boosts quality and bale purity, which increases recycling revenue opportunities. Moreover, AI-powered recycling technology helps remove humans from dull, dirty, dangerous jobs and offers a path to higher-skilled, more desirable roles in maintaining and managing the technology. Because the recycling industry has such a hard time filling these roles in the first place, technology like AMP’s help them overcome labor shortages and run fully staffed. Since inception, AMP’s technology has saved an estimated nearly five million tons of greenhouse gas emissions, an impact equivalent to removing more than one million cars from the roads (figures through November 2022; if selected, we can provide an update).

E.E: What’s moving your company forward?

AMP Robotics: AMP’s mission is to enable a world without waste. The company believes technology holds the promise of decoupling the world’s potential from environmental harm. AMP believes technology unlocks constraints in the waste industry, and use it—namely, artificial intelligence and robotics—to pursue its mission. AMP applies machine learning to differentiate waste, a core capability that has been missing from the industry. By creating sensing mechanisms for waste, AMP can bring a wide assortment of developments already advancing in other industries to benefit the recycling industry, develop novel devices that solve key constraints, and introduce transparency to the industry to help society improve its environmental stewardship.

E.E: How do employees shape your company’s future?

AMP Robotics: Some of AMP’s earliest employees started as interns and grew into long-term careers at AMP. The company regularly fields request from and lends support to students at many points in their educational journeys working on projects related to waste, recycling, and advanced technology. AMP’s employees also volunteer with local robotics programs, from coaching and mentoring teams and helping to foster the next generation of engineering talent to judging special events. The company’s diverse, growing team of environmentalists, engineers, and other professionals shares a passion for the promise technology holds to modernize the way we recycle. Broader adoption of AMP’s technology preserves valuable resources.

E.E: How does the digital transformation affect your products / business?

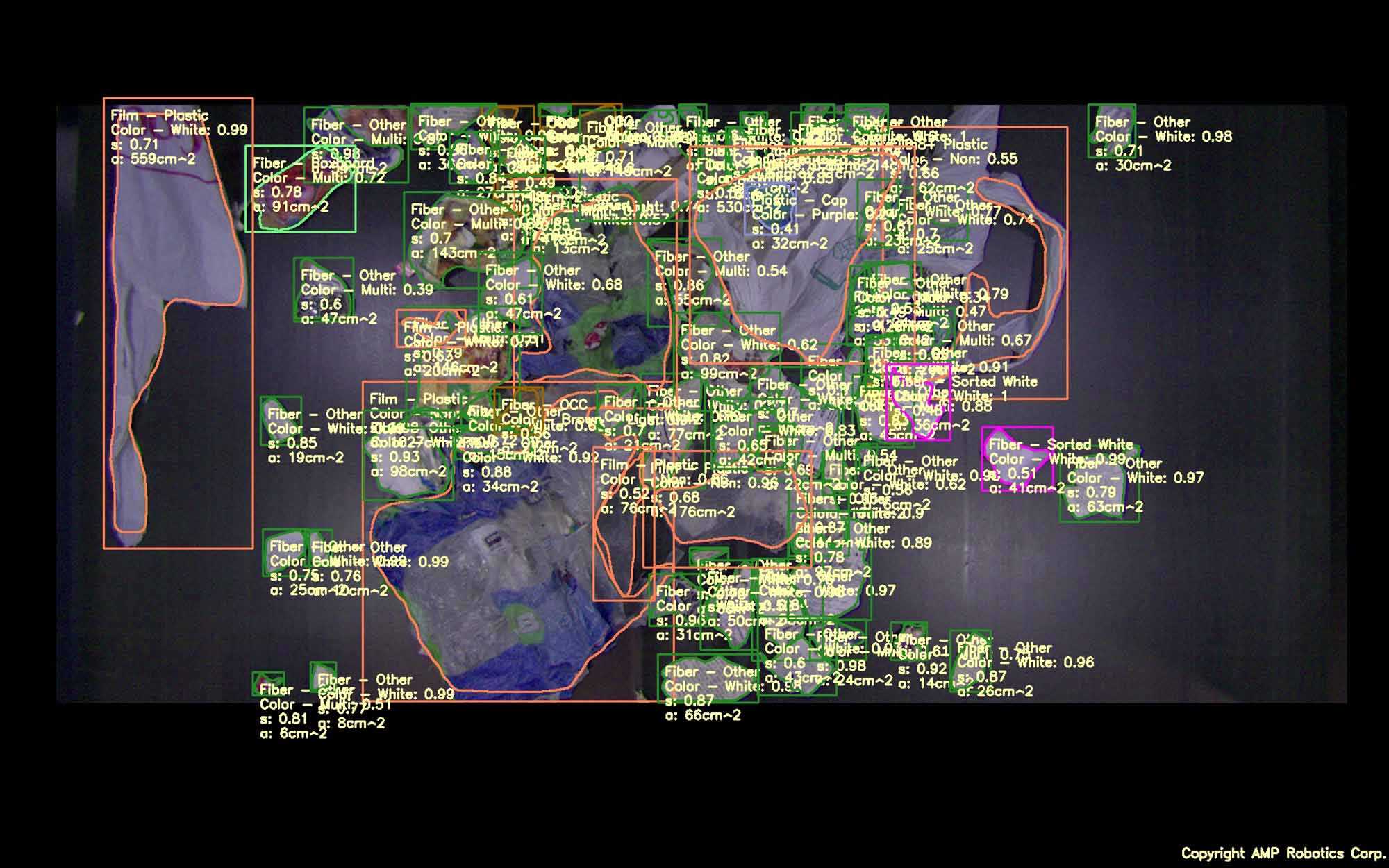

AMP Robotics: Artificial intelligence (AI) is the enabling technology essential for MRFs to generate and capture the data to optimize recycling operations. Vision-based AI software identifies and characterizes objects in the waste stream in real time, digitizing each item that passes by. These objects are captured as a new form of data, including object counts, packaging descriptions, and more, over time. At AMP Robotics, we’ve deployed hundreds of robots and sensors that process billions upon billions of objects on conveyor belts in MRFs. This effectively enables automated and continuous characterization of this material. We continue to expand our material categories by exploring and developing subcategories useful for MRFs as well as for downstream recyclers. As more robots are deployed, the industry is able to leverage the networked intelligence of hundreds of units. The more AI-based robots and sensors we deploy into production, the more a network effect is created. In the case of our systems, this network effect exponentially increases the sorting intelligence. If a challenging packaging type or new material emerges, we’re able to capture imagery and train the AI to identify the object. This knowledge is then deployed throughout the fleet of robots. In essence, the more robots we deploy, the more each customer is helping another customer by expanding the AI’s material knowledge.

MRF operators can use the data this machine learning technology produces for analysis to support inbound, outbound, and product quality questions. It also allows operators, finance departments, and material auditors to do things like graphically compare material stream data to historical baselines; define material volume thresholds and create alerts triggered by movement above or below these thresholds; export data for further analysis and integration into business intelligence platforms, and more.

This delivery of real-time monitoring and analysis of material as it flows through a facility provides visibility into and feedback about material streams, helping to overcome the perennial data transparency challenge for recyclers. With data and tangible metrics, operators can get ahead of mechanical or configuration-based issues and communicate with business partners or key staff in the facility.

E.E: Tell us about research and development in your company.

AMP Robotics: With world-class technology and a commitment to continuous improvement, AMP has become a leader in the evolution of recycling. This role involves reshaping an extractive economic model into one defined by flexibility, resource efficiency, and transparency to move the waste industry forward, while exploring expanded applications of AI technology.

E.E: How do you think the future will look like in your field of activity?

AMP Robotics: Demand for AI-powered robotics to retrofit existing recycling infrastructure continues to thrive; among historic demand for recycled commodities of all types, the industry needs capacity to meet the 2025 goals of consumer packaged goods companies that have committed to the use of post-consumer recycled (PCR) content. AMP sees growth in a number areas, from the breadth and precision of its material characterization capabilities, to new sortation verticals, like e-scrap, construction and demolition debris, and organics, to increasing use of data to improve recycling operations and help achieve sustainability targets.