ENDEGS is a provider of innovative green tech solutions for the reduction of industrial emissions. Applying the effective technologies enables industrial facilities to significantly reduce their emissions. During many industrial processes, gases and vapors develop that are harmful to environment and human health. Still too often, those hazardous emissions get into the air untreated. By reducing their emission of hazardous gases and vapors, industrial facilities can reduce their carbon footprint as well and thus contribute to global environmental protection. To support our customers in their efforts for emissions reduction and industrial decarbonization, we work hard every day.

Interview with Kai Sievers, Founder ENDEGS GmbH.

Easy Engineering: Which are the most futuristic products / solutions from your portfolio?

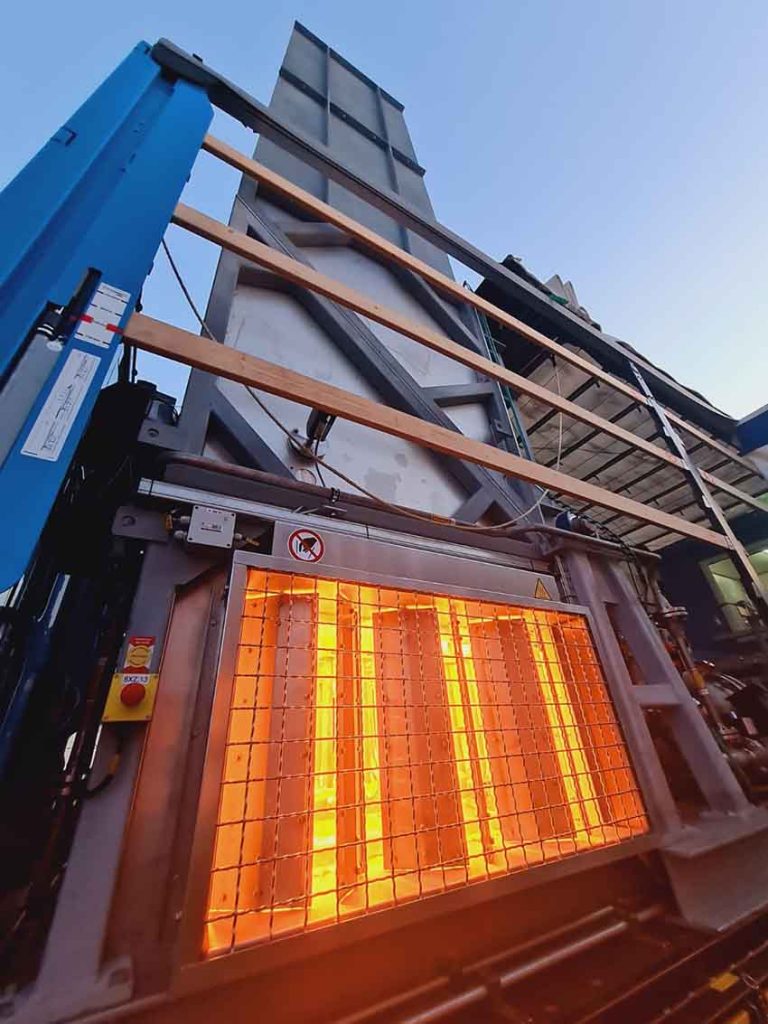

Kai Sievers: In 2008, we developed the world’s first portable, autonomously operated mobile vapor combustion unit, enabling mobile degassing for the very first time ever. ENDEGS mobile incinerators destroy all gases, gas mixtures and vapors of the explosive groups IIA, IIB and IIC with a combustion rate of more than 99.99 % and without any open flame, making us the only company operating in Europe able to do so. With our mobile vapor combustion units, all hydrocarbons, VOC and HAP emissions can be burned in an efficient and environmentally-friendly way. That makes our units perfectly suited for the degassing of all types of components like tanks, containers, pipelines, vacuum trucks, barges and vessels as well as for the temporary replacement of stationary systems for the emissions reduction such as vapor recovery units (VRU). Our portfolio of emissions reduction services is completed by a fleet of mobile vaporizers with nitrogen tanks and the remote-controlled ATEX Zone 0 robot for tank cleaning. All of our units are trailer-mounted and portable so they can be applied directly at customer sites.

E.E: Tell us about the company’s long-term goals / prospects?

K.S: In over 16 years of operation, we have successfully completed more than 1,600 projects – in each and every of these projects have we helped a customer to reduce emissions and contribute to environmental protection. Assisting others in their efforts for reducing their carbon footprint and thus contributing to improving the air quality is our main motivation. Of course, we want to continue doing that. We offer our services all across Europe with offices in Germany, France and the Netherlands. With a branch office in Saudi Arabia, we will further expand the reach of our services and make the ENDEGS technologies available for customers on the Arabian Peninsula as well, so they too can benefit and reduce their emissions. Because our mission is to lower global emissions, we want to help as many customers as possible to reduce their carbon footprint. That is our biggest long-term goal.

E.E: Tell us about product innovation and how does it impact the future?

K.S: Innovation is a very important part of our daily work – we work in many different industries such as oil and gas, chemical and petrochemical or food and fertilizer; the range of products that are applied in these industries is forever changing quickly. For example, we have recently noticed a shift toward alternative and more sustainable technologies and energy sources. As burning fossil fuels produces many emissions, industry and economy alike aim at using different energy sources to contribute to decarbonization. In that context, for example LNG and green ammonia have become important products. That of course also required the implementation of new supply chains and infrastructures.

As liquified gases under pressure, such products as ammonia, hydrogen, propane or butane are highly flammable and have a high risk of explosion. Existing technologies were not suitable to work with those products. That’s why we have introduced the new ENDEGS nitrogen services – with our new fleet of mobile vaporizers with nitrogen tanks, it is now possible to work with systems and system components that contain highly flammable products like ammonia, hydrogen or propane. By inerting and flushing them, combining our nitrogen services with our vapor combustion units enables the degassing of components containing these more complex products as well. As this example shows, product innovation is very important in order to keep up with trends in the industry and to expand the application areas of current technologies.

E.E: What’s moving your company forward?

K.S: Our innovative processes ensure that we keep improving ourselves and our technologies. But the most important part for moving ENDEGS forward are of course our employees. Without our skilled and highly trained staff, we wouldn’t be able to carry out as much projects and to support as much customers in reducing their emissions.

E.E: How does the digital transformation affect your products / business?

K.S: Further developments of our services always take place together with our customers. Over the last generations of our mobile combustion chambers, we have technically incorporated and implemented customer requests for more digitalization, networking and evaluation. We are currently working on further digitalization concerning our working processes that will help to further optimize our operations.

E.E: Tell us about research and development in your company.

K.S: In order to improve our technologies, we listen closely to the needs and requirements of our customers. Do they for example work with a product our technologies are currently not suitable for? Then of course we do everything we can to expand our services. Thus, our daily work in the field at the sites of our customers is an important part for product innovation. I have already mentioned adding the ENDEGS nitrogen services to our portfolio to be able to work with more complex products. Another example for product innovation at ENDEGS is the extension of the combustion capacities of our mobile incinerators. Previously, we only had 5 MW units before adding the 20 MW mobile vapor combustion unit. Nowadays, we also have units with combustion powers of 3 and 10 MW. This broad range of units in different combustion capacities enables a higher flexibility – for example, the 3 MW unit is perfectly suited for short-term projects and emergencies, while units with a higher combustion power are ideally for long-term projects than include more complex products.

For the third year in a row, we have been named as one of the most innovative German medium-sized companies. The jury of the TOP 100 Innovator competition particularly honored our innovative strength and innovation climate. In March 2023, we have participated in an innovation competition for decarbonization in Malaysia. More than 500 companies submitted over 3,000 ideas – of all those companies, we reached a top 20 position in the competition. Successes like these show us that we are on the right path with our technologies and product innovation processes.

E.E: Tell us about the company’s future strategies and how will you adapt to the future.

K.S: We want to continue to offer innovative emissions reduction services and aim at improving them even more. Recently, ENDEGS merged with the SIS GmbH – together, we now form the ETS Group as the European market and technology leader in the field of environmental technology for the reduction of emissions from volatile hydrocarbons. Under the umbrella of the ETS Group, we will continue our successful corporate development and want to provide even more customers with the possibility of efficiently reducing industrial emissions.

E.E: How do you think the future will look like in your field of activity?

K.S: Over the last few years, the awareness for environmentally-friendly and sustainable operations has significantly grown. More and more industrial facilities start to care for emitting less and reducing their carbon footprint. Furthermore, measures for more occupational health and safety have been taken. We expect this trend to continue, which is a very good thing. While many actions have been taken to reduce emissions and to reach the ambitious goal of climate-neutrality by 2050, more needs still to be done. However, we have also noticed that with many new technologies and energy sources arising, our clients also need more consulting to figure out what is the best tool, technical upgrade or change of working processes to be legally compliant and achieve environmental goals. For this, a lot of trust and operational knowledge is needed to consult and guide our clients the right way.