Mevea is a Finnish high-tech company providing highly advanced and innovative solutions for product development, operator training and engineering education build on physics-based digital twins. Mevea solutions produces accurate real-time simulations of machines, environments and work processes that yield tangible business benefits such as assistive and autonomous system development. The company also has a solid background in collaborating with universities and research institutes in teaching future engineers and supporting various research projects.

Interview with Tero Koskipalo, Managing Director at Mevea.

Easy Engineering: Which are some of the latest products / solutions from your portfolio?

Tero Koskipalo: For example, the past summer Mevea delivered digital twins, simulation software and training simulators to Siemens, which will integrate the solutions within its open and modular SIMOCRANE Remote Control Systems (RCOS) for remote control of all relevant crane types. The digital twins will be used in crane automation, software testing and development as well as in operator training. (Mevea has delivered Digital Twins and Training Simulators to Siemens – Mevea)

Another quite recent example is Konecranes that ordered a Mevea training simulator for Automated Rubber Tired Gantry (ARTG) crane. This simulator will be integrated with Konecranes crane PLC and Remote Operating Station (ROS) and it is used to train Konecrane’s ARTG customer crane operators. (Mevea Provides aRTG Training Simulator to Konecranes – Mevea)

E.E: Tell us about the company’s long-term goals / prospects?

T.K: In the long run Mevea aims to continue expanding to international markets and to increase awareness of Mevea’s advanced solutions, which are essential for many different industrial companies in the ongoing digital transformation. Mevea has growing partner networks, and we are happy to participate in industry events. We also organize events ourselves, albeit mostly virtually.

Speaking in the shorter term, our next major event, Mevea´s Virtual Seminar 2023, is on October 17 and it is titled as “How the World-Class Companies Stay Competitive in Autonomous & Assistive System Development?”. In this free virtual seminar, you will learn how Ammann (Switzerland), Prinoth (Italy) and Raute (Finland) – all world-class companies in their industry segments – are addressing the challenges related to assistive and autonomous system development. Since this is our 10th annual Mevea Seminar, as an anniversary bonus we´ll have also a very special guest speaker, a former chief test engineer from formula one. So, this is a unique opportunity, and we kindly suggest visiting our event page and to save the date. The registration starts on the first week of September. (Virtual Seminar 2023: How the World-Class Companies Stay Competitive in Autonomous & Assistive System Development? – Mevea)

E.E: Tell us about product innovation and how does it impact the future?

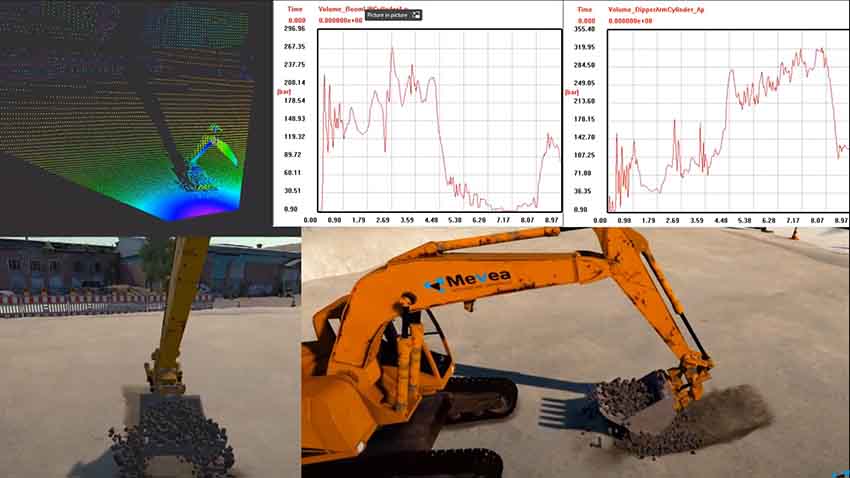

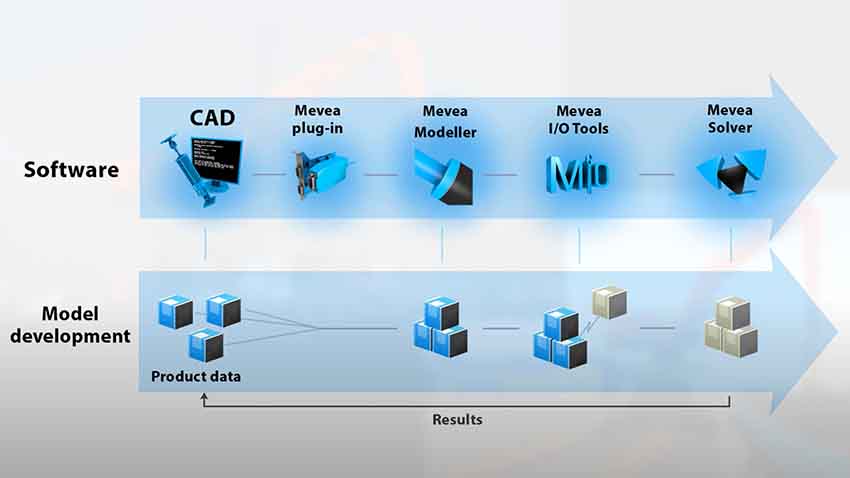

T.K: In the future, Mevea´s Digital Twin will be incorporated with the actual machine. Through interconnection and real-time data this combination will make it easier to manage the actual machine. This will also improve safety, help to predict the remaining service life and to reduce the need for physical sensors. More information about Mevea solutions for product development, click here: (Digital Twins in Product development | Mevea Simulation Software)

E.E: What’s moving your company forward?

T.K: Simply put, we are driven forward by the needs of the customer base, which in turn are largely based on changes in the market. The recent changes we have witnessed so far include increased environmental requirements and electrification of machinery. This has brought changes to manoeuvring speeds and new standards for control systems, which all have had an effect on machine loads and operator stress.

Due to electrification, more limited energy resources are available, and therefore a better efficiency must be found for power transmission. One solution to this is, for example, lighter structures. This context also includes optimization of component selections and virtual testing.

Another market trend stemming from customer needs is autonomous and remotely controlled machines as well as driver assistance systems. This complex includes the use of new sensors and cameras, safety requirements, the use of artificial intelligence and a virtual development environment.

Mevea’s approach to solving the customer’s problems is very flexible and adaptable, and therefore also cost-effective. The purpose is not to bring additional challenges on top of the old ones, but on the contrary to rationalize, enhance and increase productivity.

E.E: How do employees shape your company’s future?

T.K: The freedom and ability of our experts to innovate independently in terms of research and development is Mevea’s greatest asset and backbone. We welcome and cherish a fresh and rational out-of-the-box thinking with the ability to see the forest for the trees. Therefore, Mevea is an attractive company for talented future engineering stars as well. Technological advancements will only be as good as the engineers of the future. Taking good care of this capital is one of the reasons why Mevea collaborates with universities and research institutes.

E.E: How does the digital transformation affect your products / business?

T.K: The digital transformation’s influence on businesses that provide simulation solutions through digital twins is profound and multifaceted. The fusion of digital twins and simulation solutions amplifies precision, accelerates collaboration, and yields data-driven insights for OEMs. While challenges exist, they are accompanied by opportunities for innovation and specialization. Ultimately, the digital transformation empowers simulation solution providers to play an instrumental role in enhancing OEMs’ competitiveness and driving industry evolution into a new era of efficiency and innovation.

This is of course a welcome trend for Mevea, as our mission is specifically to support OEMs in this digital transition to come out victorious on the other side. Thus, as far as we can see, there are only more opportunities ahead. For Mevea, the key is to identify the challenges of the customers. This means that there must be information about their current systems in use, their weaknesses, and strengths, and of course their goals. Mevea sees every client’s challenge as a wonderful opportunity for themselves. We don’t dictate operating models or standards, but we are flexible, we adjust, adapt, integrate, and innovate together according to the customer’s needs and market trends. In a funny way, you could say that Mevea is like McGyver, but with better resources. Only our customer’s success is Mevea’s success.

E.E: Tell us about research and development in your company.

T.K: As mentioned, Mevea invests heavily in product development, and we continuously cooperate with several universities. However, our product development is not guided by our own vision of the future, but rather by the needs of our customers and thus by market trends. Our job is to explore and to discover the challenges and pain points with the customers, if possible, even before they find them themselves, and to offer them the most functional high-end and long-term solutions.

E.E: Tell us about the company’s future strategies and how you will adapt to the future.

T.K: Our strategy and adaptation to the future could be metaphorically described as follows. When we started a good 15 years ago, we thought of Mevea perhaps as a sun around which the planets (customers) will orbit. Nowadays we know better, and the way of thinking has changed the other way around. In other words, we consider ourselves to be, as it were, the moon, which is precisely placed in the orbit of just the right planet orbiting the sun, where the moon keeps the planet thriving.

E.E: How do you think the future will look like in your field of activity?

T.K: The next five years hold immense potential for the heavy equipment industry as it embraces digital twins and simulation solutions. The integration of these technologies will drive innovation, enhance design processes, optimize performance, and reduce downtime. Manufacturers that invest in digital twin-enabled product development and simulations will gain a competitive edge by delivering more efficient, reliable, and advanced equipment to meet the evolving demands of the modern world. As challenges are addressed and technology matures, heavy equipment product development will never be the same again.

Mevea Ltd.

Laserkatu 6

FI-53850 Lappeenranta, Finland