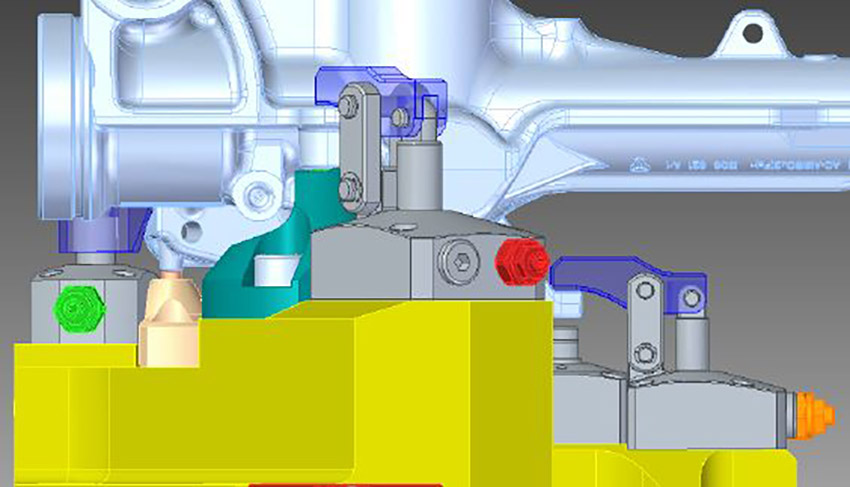

“By using low-pressure hydraulic clamping elements in the mechanical production of aluminum high-pressure-die-cast parts, we have succeeded in reducing both the maintenance costs of the machining devices and the maintenance costs of the hydraulic systems on the machining centers. The reason for this is that because of the lower hydraulic pressure required, the hydraulic unit and the lines and connections are significantly less stressed. The component quality could also be kept at the same high level in comparison with other clamping elements. Another decisive advantage is the compact design, which allows application-specific clamping fixtures to be used on smaller machining centers than before. “, said a representative of TCG Unitec, Kirchdorf an der Krems, automotive supplier with 1,100 employees and € 220 million in sales. Client since 2016.

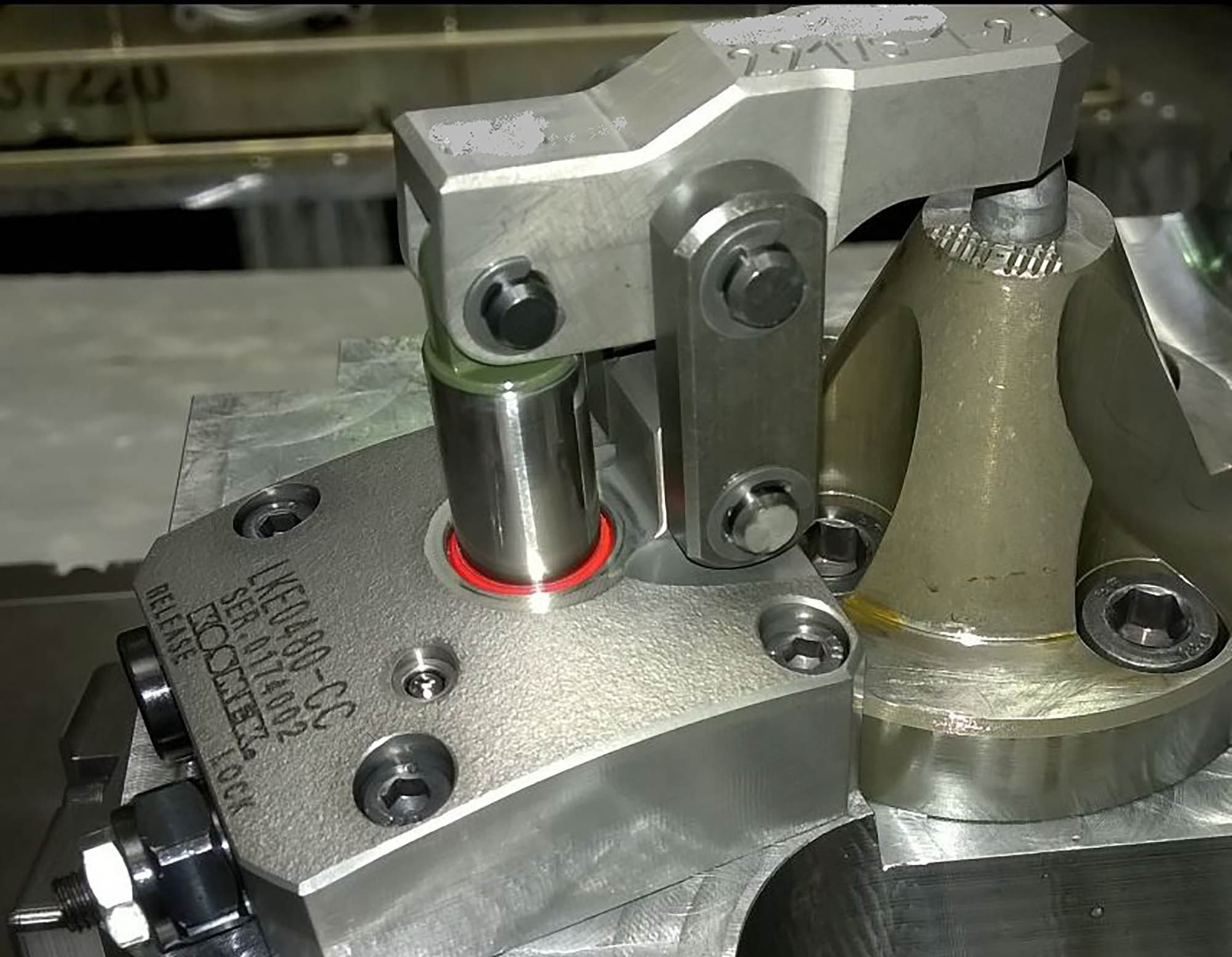

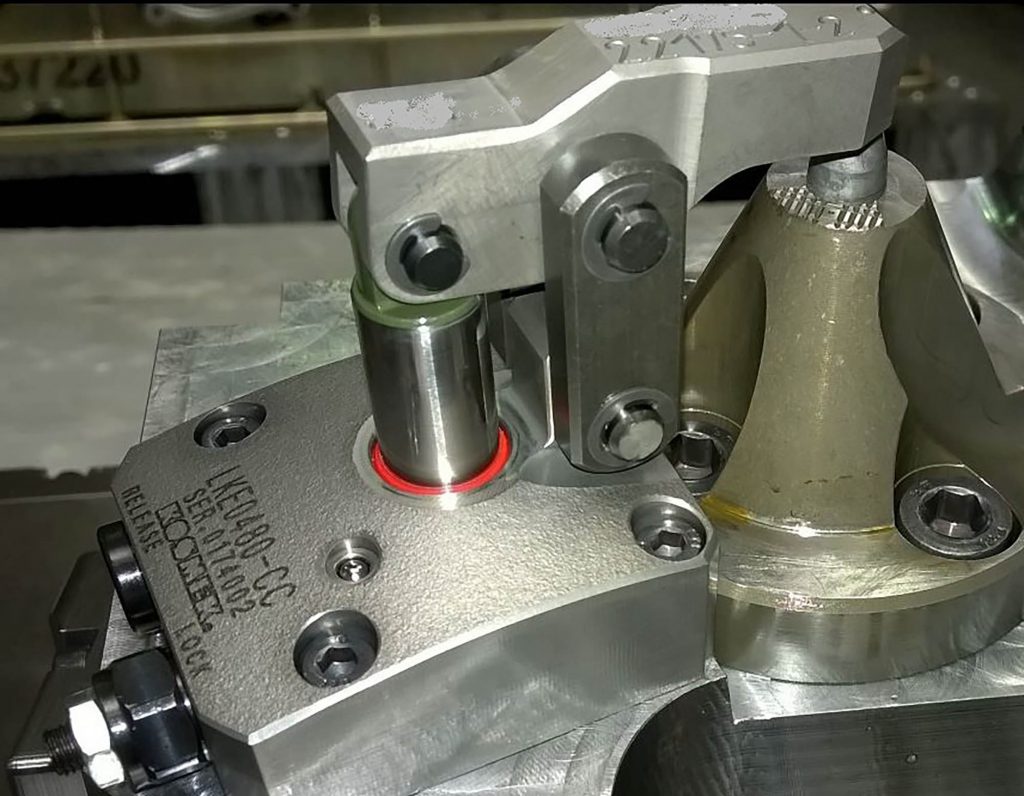

LKE High-Power-Hydraulic Clamp. 3,7 kN clamping force @ 60bar operating pressure!

Another advantage of KOSMEK components is the “sensitivity” of the applied force. Particularly with thin-walled high-pressure-die-cast components, it is crucial that the component is not deformed during clamping and that it retains its original contour after machining. In the case of high demands on the roundness of a circular milling, this becomes visible very quickly, since otherwise an oval shape would be obtained after loosening. This result is made possible by the patented “high-power-technology”.

This unique mechanism not only enables mechanical force amplification inside the clamping cylinder, which means that KOSMEK cylinders can be made more compact, it also enables the clamping point to be readjusted automatically. This means that in case of KOSMEK you do not have to tighten unnecessarily strong, e.g. to compensate potentially pressed cast surfaces, – the mechanism provides the necessary reserves in the event that this occurs.