Domat provides a comprehensive range of hardware and software products and system solutions for building, industry, energy management control and measuring systems. The company implements all kinds of system solutions, from turnkey orders and design to operation. Of course, this is accompanied by regular service and our technical support.

They have developed comprehensive family of tools and applications for energy management and building systems management, called Merbon Family. It consists of runtimes for various hardware platforms with integrated editor (IDE), HMI applications like SCADA, web server, and mobile apps, fast database for data storage, and ContPort, the energy management system. This is how customers receive a complete solution, yet open for integration with third-party systems at all levels.

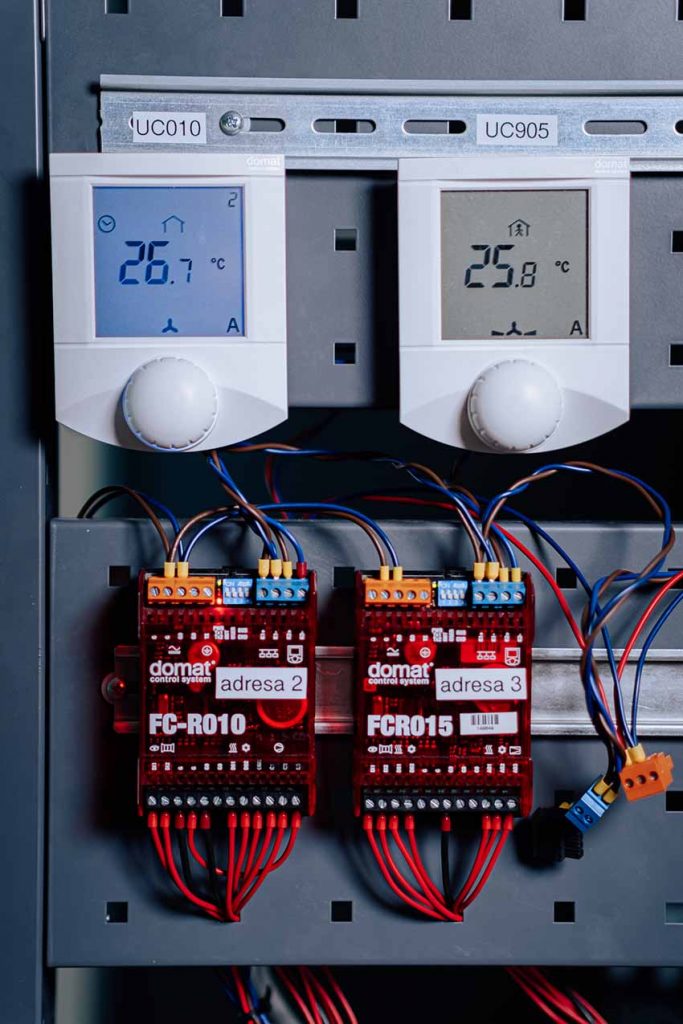

Regarding hardware, Domat supplies a complete range of control system components, such as peripherals, converters, room controllers, I/O modules, and PLCs.

Their system topology is flat which makes designing easier and enables stepwise extensions of the project with no obsolete hardware costs. Thanks to standard buses and protocols it is easy to integrate a 3rd party open device at any system level. Web access is possible at the automation level.

Easy Engineering: What was the research behind the products/solutions design?

DOMAT: When developing hardware and software products, we try to define their properties so that the product functionally covers as much of the market as possible. On the other hand, there is an effort to minimize the price, easy operation or setup and the shortest possible time to market. Therefore, sometimes the so-called customer variants (also OEM, Original Equipment Manufacturer) are created, which are based on a standard product and modified to meet the maximum performance/price ratio or offer some special features that are not generally needed, but for a particular application are a key feature of the product.

An example of a customer modification is the modification of the Modbus TCP – DALI converter, R091. The customer, the Swiss company Spline AG, uses the R091 to control lighting in residential buildings.

E.E: Which are the key aspects of the process of product/solution development?

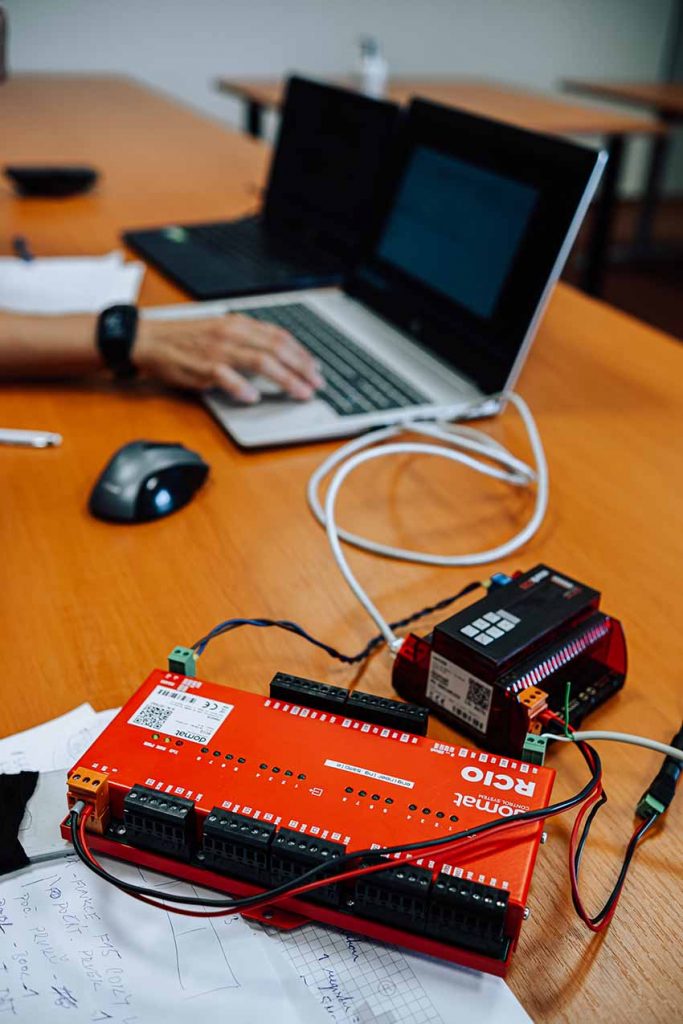

DOMAT: The first step is to get the product ideas out on the floor from our customer. The generated ideas need to be filtered through by our colleagues in the development department. Depending on the requirements of our customer, we select a product from our existing offer that would best suit the required changes. This may seem like an easy task, but not only similarity of the product is the key when selecting. The whole process is of course highly discussed with our customer, as well as all the testing and feedback.

E.E: How quickly do you adapt your products/solutions to different requirements?

DOMAT: The first requirement by Spline AG for an OEM design arose in November 2020, when they won a larger order and were able to order a minimum number of pieces, which made sense for the OEM design. The minimum number of pieces for this type of equipment is between 50 – 100 units, the exact number depends on the scope of modifications and the acceptable price increase.

By mid-December, business and technical issues had been clarified and the terms of reference agreed. In this case, the development to a fully functional and tested product, including documentation, took less than 4 months. At the beginning of May 2021, the first shipment of OEM versions of R091 converters under the name Dim-DALI traveled to Thalwil, Switzerland.

Of course, there are more time-demanding projects, such as OEM room controllers for the Quatar subway. The design specification and approval took not less than six months, as the project management and consultancy is very structured and rigid in this region.

E.E: What are the most common requirements from clients?

DOMAT: Usually, the most changes are made in the appearance and packaging. But those modifications of course are not the most difficult ones. Hardware modifications could be for example different power supply, number of I/O, adding buttons etc. As for software, changes in functionality or default configuration are the most common ones. We have our own development department, so we can really focus on customer wishes.

E.E: How do your products/solutions solve problems that your clients may have?

DOMAT: In this case, the customer installs the device in house switchboards. The Central ON and Central OFF buttons are now available on the main panel, working in the same way as the original small local switch. It is used for testing purposes and emergency control.

The system allows more flexible installation and replacement of converters in case of failure: the converters do not need to be addressed in advance, they receive addresses from a DHCP server and the link to the control system is set centrally in the service software. The possibility of password protection of web access has unified the service access with other types of interfaces that are deployed in installations.

E.E: Tell us about products/solutions innovation.

DOMAT: As for this particular product, the modifications were:

- Different color of the box – matt gray instead of transparent red;

- Company logo and graphics on the main cover;

- Graphic design of terminal labels;

- Sticker with MAC address on the main panel (used for device identification when commissioning);

- Delivery of a file (Excel) with a list of MAC addresses for easy import into the customer’s service software;

- Graphic design of the label on the side of the device;

- Indication LEDs moved to the main panel;

- Central ON and Central OFF buttons on the main panel;

- DHCP is the default network setting;

- Ability to password protect the internal web server with a freely defined password;

- Spline design configuration website.

E.E: What are the trends in product/solution design in your area of activity?

DOMAT: One of them are increasing cyber security requirements, and second is higher level of automation and integration a new technology as photovoltaics, batteries, or e-mobility. We are very active in innovating our products so that we keep up with these trends.

E.E: What are your estimations for the rest of the year?

DOMAT: We all expect to be able to see our customers again face to face, be it on trainings or product introduction meetings. Domat puts the accent on personal relations, we appreciate when customers talk to us, so the feedback is what we really are looking forward to. Regarding sales volumes, there was a slight decrease against expected figures, but the high season for building controls is still ahead, and if I look at the projects in execution, I am very optimistic.