Conveyor belts are critical components and can be surprisingly complex. Their reliability and efficiency can literally make or break an operation. Finding a genuinely tough, good quality belt that can handle the demands placed on it is difficult enough. Finding such a belt that is also competitively priced might be regarded as looking for the Holy Grail. However, Dunlop Conveyor Belting in the Netherlands have a unique design of belt that they have named Ultra X, which is proving to be not only considerably more durable and tougher than conventional ply belting but also extremely price competitive. Here, conveyor belt specialist Leslie David examines the development of an innovative belt construction that is starting to change traditional thinking on conveyor belt design.

The conveyor belt market

To be reliable and cost-effective, rubber conveyor belts used in quarrying and aggregates not only have to cope with abrasive wear but also resist damage caused by ripping, tearing and the impact of heavy, sharp rocks falling from height. The market is dominated by low grade ‘economy’ belting imported from South East Asia. In fact, it is not uncommon for European belt manufacturers to import from Asia and re-sell under their own brand in order to supplement their production and enable themselves to offer low price belting to their customers in Europe.

However, Dunlop Conveyor Belting in the Netherlands have consistently refused to do this. Instead, their approach continues to be based on ‘lowest lifetime cost’ rather than the lowest selling price by supplying belts that provide a much longer operational lifetime. Although this strategy always served them well, their research & development team has continued to search for a super-tough quarrying belt that can also compete at the economy end of the market, and in Ultra X they believe that they have found exactly that.

Designed for the task

Even the strongest, heaviest belts can be ripped, torn or punctured by heavy, sharp materials, either falling from height or becoming trapped. “Accidental damage is something that all conveyor operators have to contend with” says Dr. Michiel Eijpe, Dunlop‘s development director in the Netherlands. “Objects get trapped and belts can be destroyed very quickly. Using low grade ‘sacrificial’ belts is a false economy for a lot of reasons when you include the cost of lost production and the high cost of frequently having to repair and ultimately fit replacement belts.”.

It is a common misconception that increasing the cover thicknesses and/or the number of plies improves resistance because that is simply not the case. In fact, belts that are too thick can cause other problems such as lack of troughability and steering and handling difficulties. All the experience and evidence points to the fact that for multi-ply belts on conveyors where ripping and tearing is a problem the only genuinely effective solution is to fit a conveyor belt that has a construction that has been specifically engineered for the purpose. Such belts can have a level of resistance against ripping and tearing and cope with the impact of heavy objects falling from a high drop height that are several times higher compared to belts that use a conventional fabric ply construction. However, such belts usually have a price tag that some are unable to afford in the shorter term.

Back to the drawing board

According to Dr. Eijpe, the big challenge was to design a belt that had a much higher resistance to impact, ripping and tearing while at the same time be more economically priced. “Because our belts were already well-recognised as being the hardest wearing and longest lasting, what our engineers and technicians did was to go back to the drawing board and concentrate on the carcass construction rather than just the covers”.

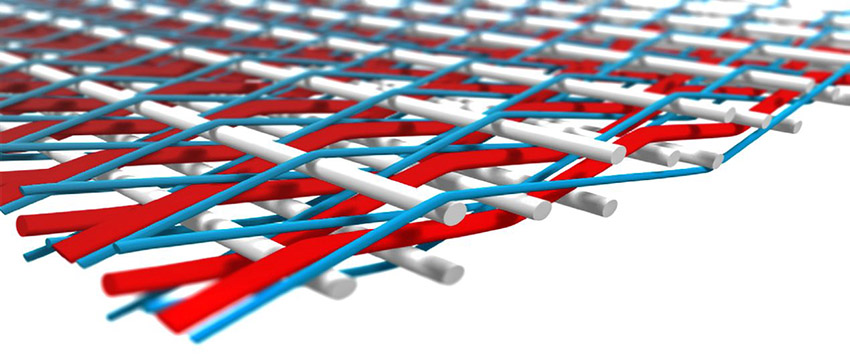

The result was a unique super-strength ‘breaker weft construction’ single-ply belt based on an amazingly tough patented fabric that is exclusively made in their Fenner Dunlop sister company’s in-house fabric weaving facility in the USA. The specially woven carcass uses crimped warp polyester yarns to provide high strength and low stretch. These are combined with strong ‘binder’ and ‘filler’ yarns to create strength and stability under load.

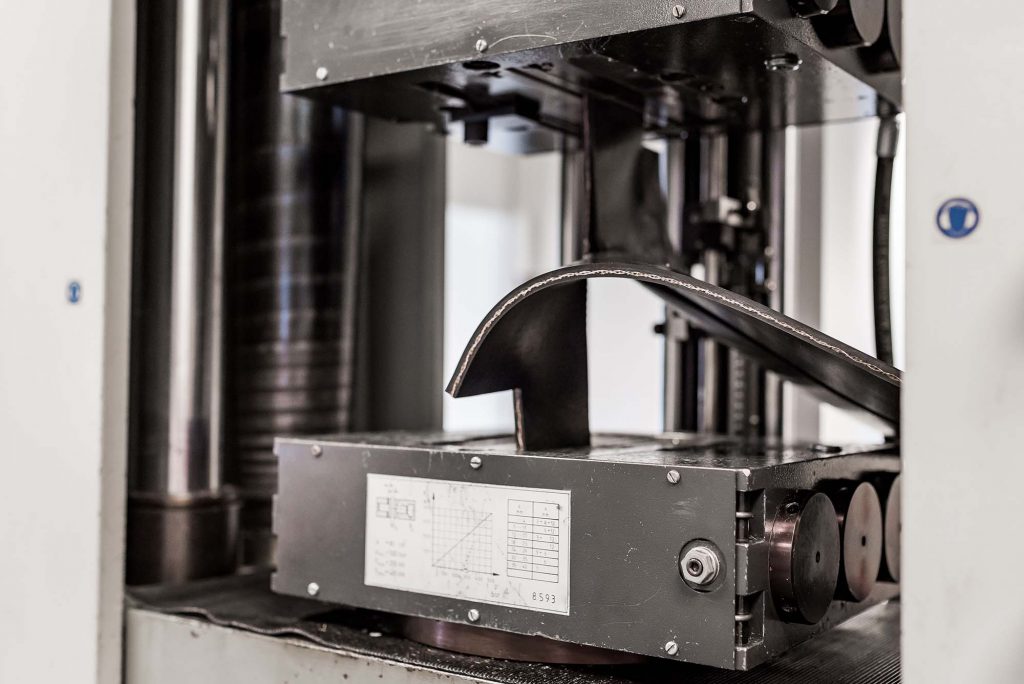

Throughout its development, sections of belt carcass were repeatedly tested to destruction, including measuring the tear resistance according to the international EN ISO 505 standard. The tests revealed Ultra X to possess more than 3 times greater longitudinal rip resistance, up to 5 times better tear resistance and a far superior resistance to impact compared to traditional 3-ply or even 4-ply belting.

A question of strength

Dunlop have made Ultra X available in two strengths – Ultra X1 (Type 330), which is designed for users of EP315/2 and 400/3 conventional ply belts and Ultra X3 (Type 550), which is designed to replace EP500/3, 500/4, 630/3 and 630/4 ply belts. The fact that Ultra X is a single-ply construction belt designed to replace conventional two, three and four-ply belts has certainly raised a few eyebrows. The first question that seems to be how a single-ply belt can provide sufficient tensile strength and yet still have such high levels of rip, tear and impact resistance? Rob van Oijen, manager of Dunlop’s application engineering department explains how and why.

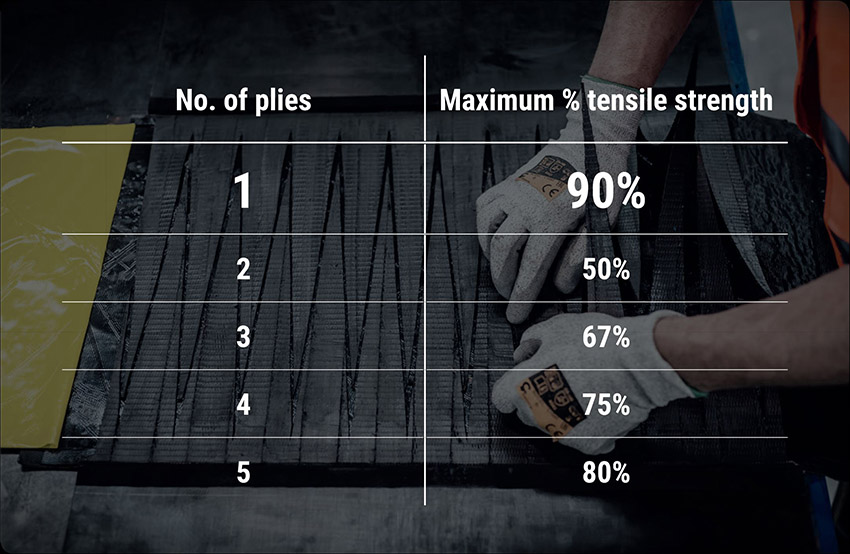

“We keep coming back to the unique fabric that we are using. Besides being able to withstand the kind of punishment that would destroy a normal belt, Ultra X has amazing tensile strength. The longitudinal tensile strength of the X1 is 330N/mm and the X3 has a longitudinal strength of 550N/mm. We stepped away from the conventional multi-layer belting for good reason. A single-ply construction requires a finger-splice joint to be made and although they take about 30% longer to make, the enormous advantage of finger splice joints is that they retain up to 90% of the belt’s tensile strength. By comparison, a 2-ply step splice only retains a maximum of 50% and a 3-ply step joint only achieves a maximum tensile strength of 67%”.

“The higher level of splice efficiency combined with the tensile strength of the X1 and X3 effectively creates equivalent tensile strengths and belt safety factors that are more than comparable to 3 or 4 layer conventional belting”.

Rob freely admits that finger splices are more costly but in his experience this reduces quite significantly with growing experience and the much longer operational lifetime being experienced more than compensates for the higher splicing cost. “The technical and economic arguments in favour of finger splicing are unquestionable. Finger splice joints are stronger and more durable. Ultra X has an appreciably better performance compared to conventional ply belt so the need to repair and re-splice joints is much less frequent”.

“To help our customers we supply the splice kits including finger pattern templates, materials and tools, a guide manual and a training film. We even provide training and supervision where warranted”. For those who still want to avoid finger splicing, the good news is that Ultra X also possesses excellent mechanical fastener retention. There certainly does not appear to be any question mark against the overall strength of Ultra X because, as their promotional film proudly states, an Ultra X3 single ply belt is able to pull up to 56 tonnes in weight.

Endless opportunities

Yet another advantage is that Ultra X is flexible enough to be used on smaller drive pulley diameters, “The X1 drive pulley diameter for over 60% rated tension can be as small as 315mm and the X3 drive pulley diameter, again for over 60% rated tension, can be as small as 400mm” says Sales & marketing director Andries Smilda. “Ultra X can run on the kind of mobile machinery that has always been notorious for having small pulley diameters where the dynamic stress placed on the inner carcass and splice joint by the continual flexing over small diameter pulleys seriously limits what can be fitted. Ultra X overcomes that problem”.

Under the radar

When Dunlop first launched Ultra X it was a deliberately low-key affair and under the radar of most of the market. Andries Smilda explains that they had many reasons for taking such a cautious approach. “We knew from the years of research and intensive laboratory testing that we were onto something special. But Dunlop being Dunlop we still wanted to prove it in the field so we worked with several tried and trusted end-users”. “Having sold many tens of thousands of meters has confirmed beyond doubt that Ultra X is all that we thought it would be and more. We have not had one single complaint or technical issue”.

Dunlop’s claims certainly seem to be supported by the evidence. Ultra X is now the belt of choice in the biggest quarry in Europe while several OEM’s have reported that Ultra X has more than doubled the average belt lifetime on their machines. In France, since replacing conventional multi-ply belts with Ultra X, a large aggregates quarry has seen an 87% improvement in productivity thanks to a dramatic reduction in stoppages caused by broken splices and other repairs. In Spain, one delighted cement plant operator has already seen a 50% increase in operating life and the belts in question still look a long way from being near the end of their lifetime.

Competing on quality and price?

Dunlop are very open about the need to be able to offer prices that are at least comparable (and often lower than) multi-ply belting. “We would never would ever comprise on quality for the sake of competing on price. That is simply not our culture and it is not necessary anyway because there are several reasons why we can price Ultra X so competitively” says Mr. Smilda.

“Firstly, the single-ply carcass is made from fabric that we manufacture in-house. That is a big, big advantage in terms of quality and cost. Having a single-ply construction also helps to maximise efficiency of production because there are fewer calendar runs. And having no rubber skim between the plies not only results in a thinner, stronger carcass, it also keeps the cost down. We are also making longer production runs at a maximum width of 2000mm”.

A cultural change?

To many, the idea that a single-ply construction belt can provide the necessary tensile strength while possessing considerably more resistance to ripping, tearing and impact is difficult to comprehend, especially while also competing on price, which is something Dunlop are not usually recognised for. However, conveyor operators can perhaps look beyond traditional beliefs and thinking then I strongly suspect that Ultra X really could be a real winner for them.

Autor: Leslie David

After spending 23 years in logistics management, Leslie David has specialised in conveyor belting for over 14 years. During that time, he has become one of the most published authors on conveyor belt technology in the world.