ECOL GROUP is a family business founded in 1975 and located in the north of Spain. Their core business is the design, manufacture and installation of customized industrial machinery. ECOL are experts in providing tailored solutions 100% engineered and manufactured in-house.

The company’s engineering team has the mechanical and electrical knowledge and the experience to provide a cost-effective solution to the customer needs. It can also manage all project stages from the technical proposal, specifications review, detailed design, layout customization, project management to the automation programming, etc.

Their workshop is equipped to carry out all manufacturing operations: cutting, welding, machining, assembly, sandblasting, painting, electrical installation, testing, etc.

Easy Engineering: What are the main areas of activity of the company?

ECOL: ECOL has a long experience working within the glass industry. Our know-how covers all manufacturing processes (i.e., production, transformation, handling, storage, etc.) for different products (i.e., flat or bent glass) for different end applications (i.e., architectural, automotive, security, etc.)

ECOL works on turn-key projects basis. Starting from the customer need, we issue a technical proposal and a budget price. In case of order, we carry out the engineering design (both mechanical and electrical), the manufacture and the assembly for pre-acceptance test at our workshop. Finally, we proceed with the packing and delivery to Customer plant where final integration tests and reception takes place.

E.E: What’s the news about new products?

ECOL: ECOL is familiar with the state-of-art machines but keeps continuously developing new products and upgrades following customer needs. Actually, our greatest added value remains in the tailored solutions and ad-hoc designs for tricky layouts, special glass sizes or high velocity lines.

For instance, most recent car designs show a clear preference for ultra large windshields and sunroofs. As a result, glass OEM have to adapt their manufacturing lines in order to deal with these new complex shapes, high curvatures and reduced thickness. In this way, ECOL has engineered and implemented some upgrades to its washing machines in order to ensure a perfect wash and drying. Since the first experiences in service have been very successful, we are now proud to offer washing machines able to receive these special windshields.

E.E: What are the ranges of products?

ECOL: AUTOMATED SOLUTIONS

- Load/unload lines

- Cutting lines

- Serigraph lines

- Quality control lines

- Component pre-assembly lines

- Packing lines

- Rotating tables

- Conveyors: Roller conveyors, Belt conveyors, Modular conveyors, Plastic chain conveyors, Hinge conveyors, Folding conveyors

- Transfers: Terrestrial transfers, Aerial transfers

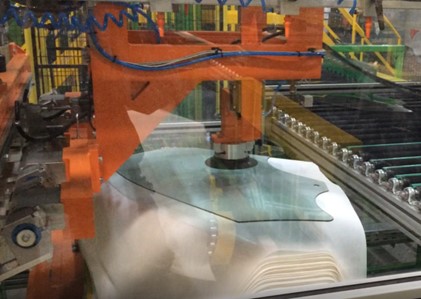

- Robotic cells: feeding/collecting parts on conveyors, loading/unloading furnaces, trimming laminated windshields, parts assembly, packaging, collaborative robots

MACHINES FOR AUTOMOTIVE GLASS

- De-airing Vacuum bag furnaces

- Washing machines for curved glass

- Drum for heated PVB

- Automated packing machines

- Centering devices

- Flip-over devices

- Turning devices

- Straight PVB cutting machines

- Trapezium PVB cutting machines

- Breakout device for wired glass

MACHINES FOR FLAT GLASS

- Washing machines for flat glass

- Aerial auto loader

- Smart warehouses

SPECIFIC COMPONENTS

- Tin bath periphericals: Inlet and exit coolers, Side sealings, Dross box, hood, lip plate, dedrossing pocket

- Coater, laminated and silvering lines

- Racks for glass storage

- Crusher & cullet system

E.E: At what stage is the market where you are currently active?

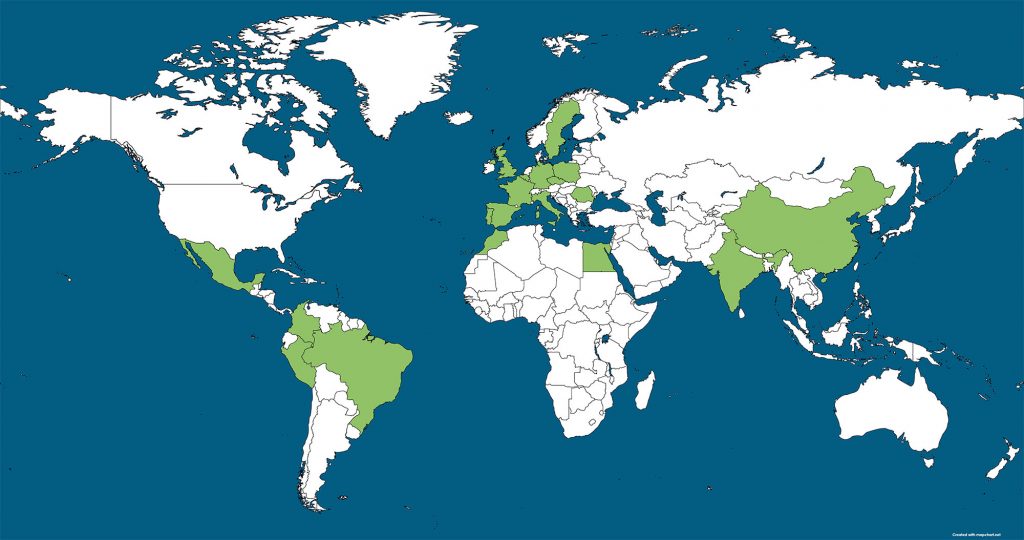

ECOL: ECOL machines are already present in many countries. We can proudly show international references up to date: Mexico, India, Egypt, Romania, Colombia, Czech Republic, Italy, China, Portugal, Morocco, Poland, Brazil, France, Germany, etc.

Although there are big differences among countries and plants, the glass machinery market is in a quite mature stage. It is a highly technological business where successful references and a reliable track of records are required to enter. Such machines represent a key investment as they are essential to the productivity and profitability of the line. Main players are well-known. Suppliers are very specialized, but customers also know their own process and needs by hand. The big plants usually have their own engineering department advising along the investment process.

E.E: What can you tell us about market trends?

ECOL: Automation is clearly the trend. Glass manufacturing is getting more and more challenging due to the evolution towards extra-large dimensions and complex shapes. As a result, all manufacturers seek to automate as much processes as possible. It allows not only to boost productivity while reducing labor cost, but also to maximize their glass quality with a lower rejection ratio.

ECOL develops automation solutions for both new and revamped lines. Our designs are compatible with the industry 4.0 concept where all manufacturing parameters of every piece of glass are recorded. In addition, we guarantee total compliance with the most recent safety standards and a strong commitment with the energy efficiency. Energy savings are essential in the current energy crisis scenario but also an environmental sustainability target for the daily operations.

E.E: What are the most innovative products marketed?

ECOL: Our biggest and most innovative machine is the vacuum bag furnace for de-airing laminated automotive glasses. Currently, it is the most advanced technology for the windshields, sunroofs and sidelites manufacture. It is fully automated and allows for flexible productions of different glass shapes with very fast manufacturing cycles.

Glasses are loaded into individual rubber bags and follow a Ferris-wheel cycle along several sections where heat and vacuum are applied together. This treatment ensures a perfect assembly between the 2 glasses (external and internal sheets) and the PVB plastic interlayer.

The machine extends for dozens of meters in length and can carry hundreds of glasses at the same time. Since bags can receive glasses of very heterogeneous dimensions, production can make changes in the manufacturing glass model without any interruption of the process.

E.E: What estimations do you have for 2023?

ECOL: After years of success in the European market, ECOL plans to grow and continue with the expansion process to new markets. The commercial department has been reinforced with new people seeking to strengthen the marketing actions including the presence on the main glass magazines and international congress.

Please contact us with your automatization needs and investment projects. We will be delighted to advice and quote a competitive solution!