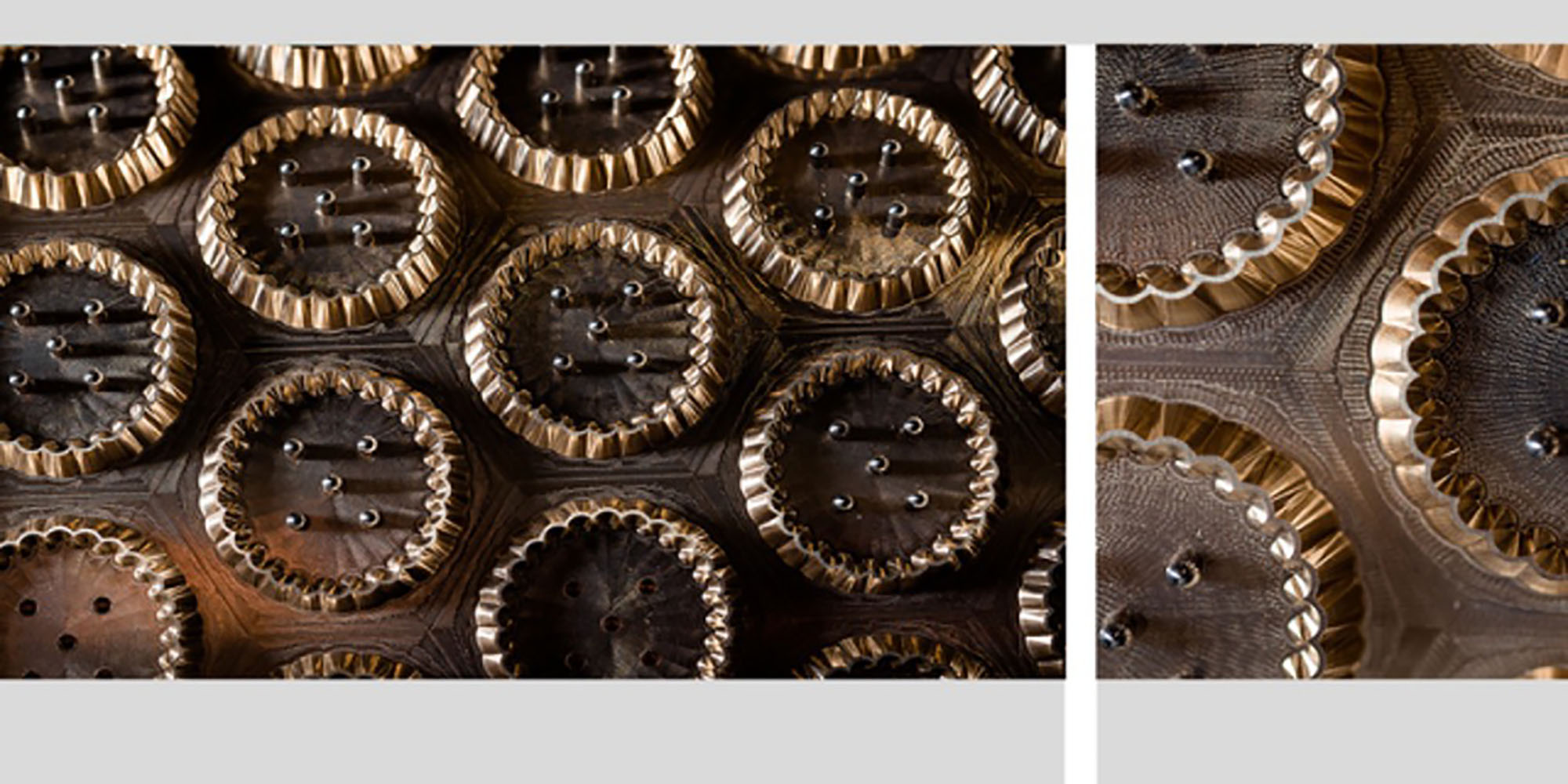

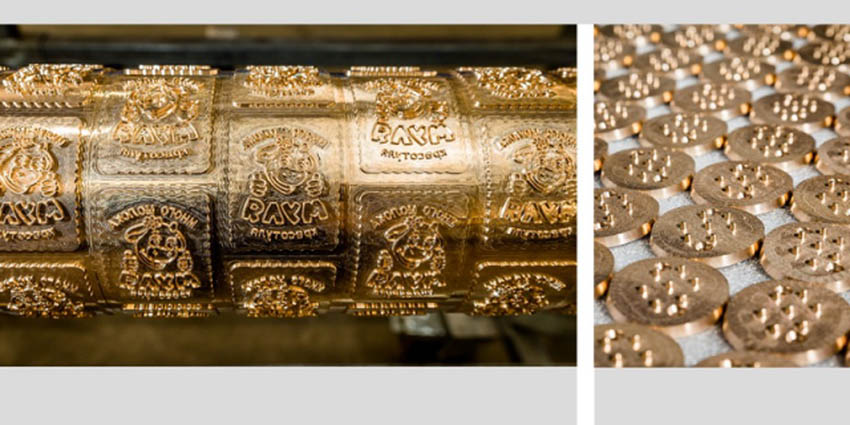

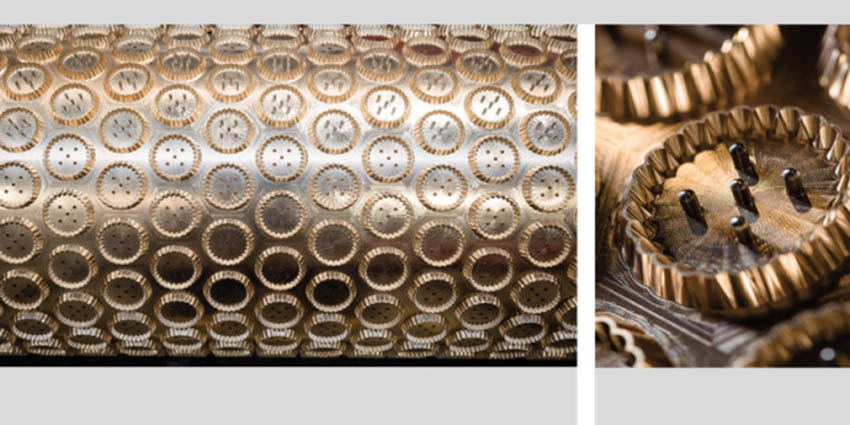

Errebi Technology is a world-famous Italian company making biscuit and cracker rotary moulding rollers and rotary cutters since ever. Ours is a long experience though decades with more than 60 years in this field! Our company has been growing continuously with the purpose of proposing more and more technological items to the biscuit production world.

We have invested in high technological machineries and human resources for guaranteeing high precision in the final work. Thanks to the employment of highly skilled staff, we are able to create or reproduce any kind of biscuit shape you desire and prove customized and personalized solutions.

Since 2011, we have moved our headquarters to a more modern and efficient building (almost 4 times bigger than the old one) and we have also increased our operating units (with additional CNC machines centers guaranteeing a very significant level in terms of accuracy of the final product).

Besides, we have also focus in researching for more innovative materials also in connection with an Italian University.

Errebi Technology has adopted since years a quality system for checking both quality parameters of our suppliers and of our high technology applied to our items.

No matter of saying that we have all certificates of compliance “food contact” for all materials used. We also apply an internal control with the use of special tools for analyzing bronze and its lead contents.

Errebi Technology’s mission is the complete satisfaction of our customers in terms of quality, reliability, high technologies of performances. We know that nowadays the world of biscuit has become more and more fix in its rules with the need to produce biscuits whose even weight and engraving designs are in line with such needs.

Our range of products goes from biscuit and cracker to pet food and pizza and ice-cream biscuits rollers and cutters.

At this purpose, we apply the most suitable materials guaranteeing lasting in time against abrasion, when abrasion represents more and more an issue in biscuit process production due to critical ingredients being used in the recipes (whole wheat flour, dry fruits, seeds, fibers…); while from the other side, we guarantee proper release of the dough from the mould.

Who doesn’t know cookies? A food that has accompanied our diets for centuries. An element that over the decades has evolved into something increasingly sophisticated and specific. The common denominator of this piece of cooked dough is that it is “easy-to-store”, “easy-to-carry”, “easy-to-use”, in other words it is a convenient and versatile ready-to-use food. The greatest strengths of this product are identified in the fact that it can often be a valid substitute for a quick meal, especially for younger consumers and with very low costs thanks to the quantity of volumes produced (mass market products). It satisfies a need for nutrition (for example, single portions of biscuits circulate in Egyptian schools to help feeding students); it can be a valid substitute for a meal, no longer consumed only for breakfast, but also as a snack. Without forgetting the opportunities for biscuit development thanks to its flexible nature that lends itself to diversifying with product ranges changing according to the proposals of producers in parallel with the ever-changing demand of consumers. The biscuit can have a unique, original taste and cover an important slice of the market, especially if offered at low costs. More and more space is being made in balanced diets as an ally to promote a healthy diet, thanks to the inclusion of natural, organic ingredients, etc. Today more than ever, it is important to follow demand, but it is equally important to anticipate the times and continuously renew products.

Market strategies play a fundamental role in this. Although the definition of biscuit as a “small piece of cooked dough” is reductive and limiting, from our privileged position as Errebi Technology we can actually confirm that biscuits are a constantly evolving market. Playing with new shapes, new recipes and ingredients that refer to the tradition of our ancestors; or the use of alternative production processes, “restyling” a classic product that you want to maintain and stabilize. It is important to renew the current ranges by working on the nutritional perceptions of the product. It is important to create the demand. For this reason, the classic brands have understood how, now more than ever, they must be close to the consumer by offering him a product transmitting trust, value and credibility, in a world full of uncertainties. And it is precisely on the basis of these objectives that various types of biscuits are developed, each with its own characteristics. In other words, this apparently simple product continues to be an element favored by the long tradition of great producers surviving thanks to their strong brand power. However, it should not be underestimated how in recent years the market has been undergoing continuous transformations that threaten the position of the large traditional brands: the development of lines of organic, dietary, gluten-free products, as well as the growth of small producers and / or private labels. Without forgetting the fierce battle over prices and imitations.

The protagonists of this dynamic market are the biscuit producers on one side and the biscuit consumers on the other side, both engaged in mutual interaction considering that the biscuit producers offer something that can (or cannot) be accepted by the consumers. And such consumers, from their side, ask for something that cookie manufacturers may or may not achieve. Over the last few years, the experience of Errebi Technology, thanks to its R&D studies in terms of materials and designs, has made it ever more possible to carry out projects that seemed impossible for their shape, or kind of dough recipe or size required to make things even more complex, increasingly severe legislation has been added in the use of materials. And here Errebi Technology is once again engaged in the search for innovative materials that offer excellent performance, but always in line with the respect of food certifications.

Errebi technology always seek for each particular case the most suitable solution for the creation of a mould that is not a simple dough moulding tool, but rather a precious means that allows to satisfy needs with multiple facets: the creation of a high quality and accurate defined biscuit trying to limit the costs involved in the process. In other words, we are always ready not only to accept the challenges that are proposed in terms of continuous evolution on the market that requires continuous evolution in terms of technology (construction and materials), but also to offer complete assistance and to encourage the development of new trends with suggestions dictated by experience, without ever forgetting to put our past at the service of future developments. We like to quote John Ruskin saying “It is important not to pay much but worse is to pay little. When you pay a lot, you spend some money; but be careful because when you pay a little, the risk is to lose everything, because what you bought most likely will not be up to doing the job for which it was bought “.

A few considerations about new trends, deeply influenced by Covid-19. The world was under the illusion that after the first pandemic wave we would have come out, although certainly, and for many reasons, no longer as before. Unfortunately, this was not the case and we have been all involved in other waves that has forced us to consolidate those “new habits” acquired with the first wave (masks, social distancing, lock down, smart working…). Food consumption at home has continued to increase, definitely going against the trend with the increase in consumption outside home that had historically occurred in recent years due to the increase in commitments outside home of the whole family. This stagnation of out-of-home consumption is occurring in all areas of the world, from North America to Europe and Asia-Pacific. In this new reality where the word “uncertainty” reigns supreme, the challenges related to safeguarding and protecting health are ever greater for each of us. The most recorded trends are waste reduction, recycling and online shopping. Once again Errebi Technology is witnessing a consolidation in the consumption of biscuits, as had already been seen in recent months. Many biscuit factories focus their production by optimizing their current and classic products. In fact, it has been seen that in times of pandemics, people are looking for elements giving them certainty and tranquility. And one of these elements can be breakfast, but not made with any products but with food that refers to tradition, to the happiest memories of one’s childhood.

It goes without saying that (classic) biscuits therefore constitute a rediscovery, a tool that for a moment removes the climate of uncertainty to make us dive into more carefree moments. Here is how, various biscuit factories, riding the wave and responding to the needs of consumers, offer the same products of the past, possibly made healthier (palm oil free, no added sugars …) to encourage more consumption, persuading the consumer that the organic or health products can definitely contribute to a stronger immune system. We remind you that for the realization of this range of particular products, special rollers are required in terms of materials (to have good release from the mould even with increasingly critical doughs and to resist the abrasion of recipes that are increasingly rich in cereals, dried fruit, inclusions) , as well as in terms of designs.

Errebi Technology is always at the side of its customers to assist them in the best possible way, whatever the shape, the design or recipe to be made. For more information you can visit our website www.errebi.net and at the section “news” for being update with trends.