Evident was established on April 1, 2022 as a wholly owned subsidiary of Olympus comprising its former Scientific Solutions business. The company started the journey as a fully independent company on April 3, 2023 through a partnership with Bain Capital. Building on a history of more than 100 years of innovation, Evident is committed to making people live healthier, safer and more fulfilling. Evident supports customers with solutions that solve their challenges and advance their work in the life science and industrial markets.

Headquartered in Tokyo, Japan, Evident conducts business in 24 countries worldwide with more than 4,300 employees.

Interview with Tobias Ruckes, Global Corporate Communications Leader at Evident Scientific.

Easy Engineering: What are the main areas of activity of the company?

Tobias Ruckes: Evident’s industrial solutions range from microscopes and videoscopes to nondestructive testing equipment and X-ray analyzers for maintenance, manufacturing, and environmental applications. Backed by state-of-the-art technologies, Evident products are widely used for quality control, inspection, and measurement. Our life science solutions empower scientists and researchers through collaboration and cutting edge technologies. Dedicated to meeting the challenges and supporting the evolving needs of its customers, Evident continues to advance a comprehensive range of microscopes for pathology, hematology, IVF, and other clinical applications as well as for research and education.

E.E: What’s the news about new products?

T.R: Let us introduce the following six new products:

We just launched IPLEX G Lite-W, an industrial videoscope developed mainly for wind turbine gearbox maintenance and designed for faster wind turbine gearbox inspection. An oil-cleaning tip adapter enables users to see clearly in oily environments and an oil-resistant insertion tube coating allows easy cleaning.

Our next-generation HydroFORM™ scanner builds on the field-proven design of its predecessor. This two-axis encoding corrosion mapping solution iseasy to deploy and optimized for a single operator. The semiautomated scanner enables fast and reliable wall-thickness mapping and midwall damage detection by acquiring high-resolution data of large surfaces in minimal time.

Our new Vanta™ GX precious metal analyzer provides an easy and affordable way to verify the purity and composition of jewelry, gold, and more.

E.E: What are the ranges of products?

T.R: Evident Industrial’s solutions range from microscopes and videoscopes to nondestructive testing equipment and X-ray analyzers for maintenance, manufacturing, and environmental applications.

Evident Life Science advances a comprehensive range of microscopes for pathology, hematology, in vitro fertilization (IVF), and other clinical applications as well as for research and education.

E.E: At what stage is the market where you are currently active?

T.R: Overall, we recognize upward trends in the markets we operate in, especially in the aerospace, power generation, oil/gas & chemical, government security, infrastructure (specifically railway), scrap metal recycling, and the electronics and semiconductor markets.

The growth in the automotive market is largely attributed to the increased demand in electronic vehicles, resulting in an increased demand for our measurement and inspection solutions.

We are also active in data-rich systems like the Cloud and Internet of Things, connecting our products for data-sharing and remote work, and robotic technologies, enabling users to sense and control objects remotely, streamlining complicated processes.

E.E: What are the most innovative products marketed?

T.R: Non-destructive testing (NDT):

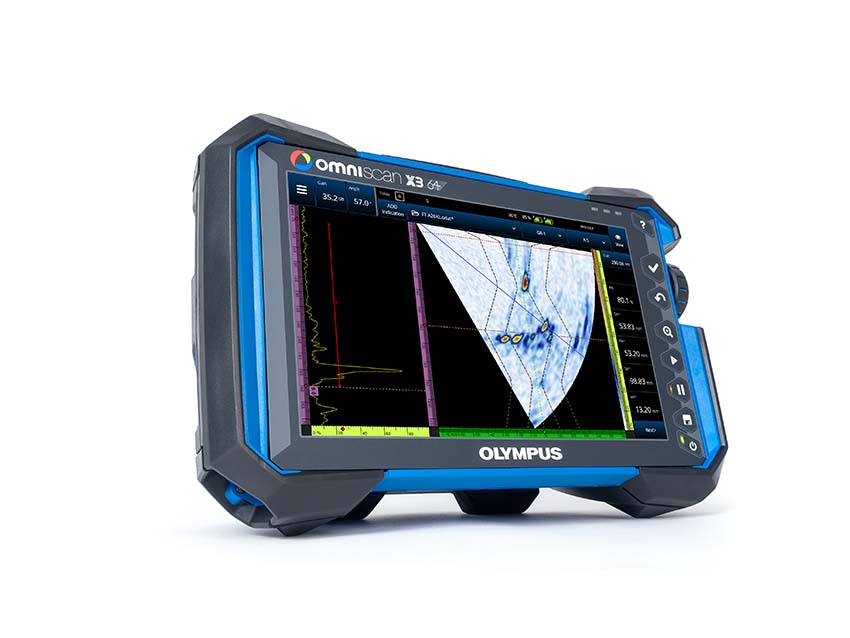

Our OmniScan™ X3 64 flaw detector featuring phase coherence imaging (PCI) technology is quickly gaining attention in the NDT industry for its capacity to generate easy-to-interpret images of oddly oriented cracks and minute flaws. It also excels at imaging typically challenging-to-detect defects in “noisy” materials.

The 72DL PLUS™ ultrasonic thickness gauge delivers precision thickness measurements at high speeds in a portable, easy-to-use device. With fast scanning, advanced algorithms, and our lowest-ever minimum thickness capability, it can accurately measure the thickness of very thin layers in the most challenging applications.

Remote visual inspection / Videoscopes: Videoscope IPLEX NX with super wide stereo measurement and workflow software solutions.

Microscopy:Our augmented reality (AR) solution for our stereomicroscopes allows faster and more efficient assembly in medtech and electronics industries, reducing the risk of human error.

DSX1000 digital microscope for industrial applications featuring a “macro to micro” solution with lenses and observation methods that can be switched instantly.

X-ray fluorescence: The Vanta analyzer the our most advanced handheld X-ray fluorescence (XRF) device for customers who demand laboratory-quality results in the field. It provides rapid, accurate elemental analysis and alloy identification for high-throughput XRF testing.

E.E: What estimations do you have for 2023?

T.R: We are working on the expansion of our workflow solutions for aerospace, power generation, electronics & semiconductor, and EV markets, from which we expect increased demand.