Patrik Johansson and Alexander Johansson are the passionate construction team, located in Karlstad, Sweden, behind the pioneering EWS – Electronic Work Station. Patrik is one of the worlds most experienced constructors of flatbed applicators and workstations for lamination. The EWS is the 5th generation of applicators he has constructed. Patrik started with the RollsRoller Flatbed Applicator, then the CWT and after that the Roll-X.

Interview with Patrik Johansson, CEO of EWS – Electronic Work Station.

Easy Engineering: A brief description of the company and its activities.

Patrik Johansson: My main goal was to design the most user-friendly workstation on the market. Therefore, we had to use the most reliable and modern technology in order to eliminate all the experienced problems within the laminating process.

The conclusion was that previously used compressor technology had to be replaced.

We found the latest as well as the most proven and reliable technology: the one used in 3D-printing machinery.

This technology gives a precise and even control of the pressurized roller on the EWS workstation.

Going into electronics also give us opportunities for future upgrades of coming new innovative solutions for the EWS workstation. Production optimization in order to reduce manufacturing cost was also very important.

Had I known what an enormous amount of work it would take to construct the EWS, I would probably have hesitated to start in the first place, but Alexander pushed me forward and forced me to think in a new direction so I’m glad I didn’t. We made it! The EWS is here!!

E.E: What are the main areas of activity of the company?

P.J: Superior Ergonomics

The EWS Workstation is designed to be the most user-friendly and ergonomic workstation on the market. The ergonomic benefits create a positive impact on employee health, efficiency and, as a result, better economy.

The electronically controlled pressurized roller makes it possible to work anywhere on the table, no more:

- uncomfortable stretching into the middle of the table.

- use of supporting posts during application.

- damaged sign material.

We aim towards the markets of sign-makers, traffic sign-makers, car-wrapping, the possibilities of the EWS is endless.

E.E: What’s the news about new products/services?

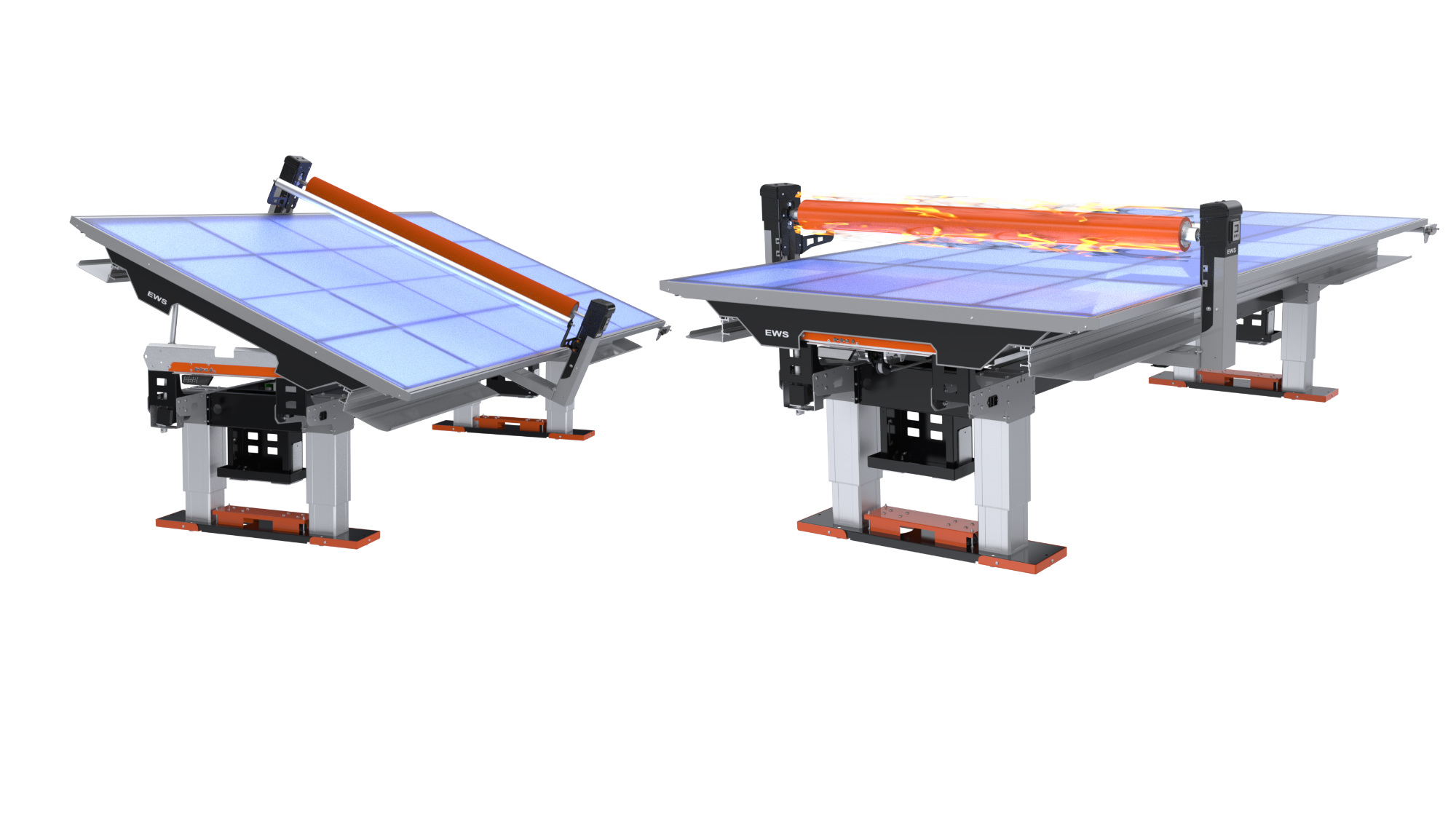

P.J: The EWS-table is news in itself. A lot of the features on our products are news in the industry and we continuously work towards improving the ergonomics and user-friendly attributes. Some of the characteristics are the Heat roller 30-60° (86-140°F) Reducing silvering in the application process. Designed to give an even temperature along the complete working area of the table during the application process. Motordrive that operate the glidebeam and the roller with a remote control at a constant speed to avoid an uneven longitudinal application. The Motordrive has four different speeds. LED backlighted surface with variable brightness makes it easy to use crop marks. Ergonomic tilt function where the table tilt up to 25 degrees to get a comfortable working position for anybody regardless of ergonomic preferences. Motorized adjustable table height makes it easy to get a comfortable working position. Foldable glidebeam for a maximized working surface e.g. when working with large formats.

E.E: What are the ranges of products/services?

P.J: We two different series called the X2 and X4. Both of these series are available with different feature-packages, Essential our base model with the most crucial features for an economical application process. Advance with the most crucial features as well as: Ergonomic Table Tilt and LED Illumination.

In addition to those packages we the Performance Heat. A fully equipped X4-table with all the features for the most demanding application processes.

E.E: What is the state of the market where you are currently active?

P.J: The market in which we aim to be, is always booming! We have a lot of international interest in our products and with the never-ending area of usage they provide, we believe the market will keep growing.

In a lot of parts of the world you also have growing demands on the work-environment to have less strain on the employees, so the ergonomic “standpoint” we have taken upon ourselves is also right in line with the demands of tomorrow!

E.E: What can you tell us about market trends?

P.J: The EWS, the way we see the current state of the market and were the industry seems to be going, we belive the trendsetter is the EWS with the revolutionary DACT-tech! Beyond the technical keys of the new generation of products, we also have the new generation’s design, sleek and modern! With smart solutions for everything from storage to transportation. Designed and manufactured in Sweden!

E.E: What are the most innovative products/services marketed?

P.J: Our patented DACT (Digital Adjustable Click Torque) Technology is a truly technical paradigm shift for flatbed applicators. The disadvantages with traditional analog technology based on an Air Compressor controlled Roller is now passed into history and replaced with our modern Digital Technology – DACT.

The DACT Technology is based on an electronically controlled pressurized roller. This ensures the roller will be exactly parallel towards the table surface. Due to the DACT Technology, the application process does not need to be done in the exact middle of the table. No damages on pressure sensitive materials in corners or ends of the material. Supporting posts are not needed during application.

E.E: What estimations do you have for the beginning of 2024?

P.J: In the beginning of 2024, we are working towards further growing the brand and knowledge of the EWS-Electric Workstation. We are looking for additional markets and constantly looking for partners and distributors all around the world!