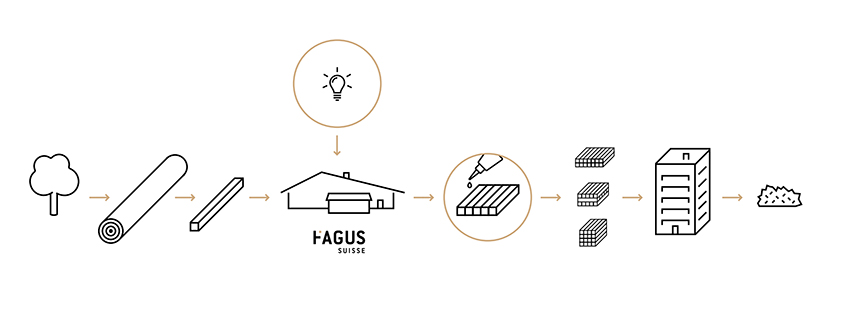

The Swiss company FAGUS SUISSE SA produces high-strength elements for structural timber engineering from domestic hardwoods. These can replace steel and concrete and massively improve the CO2 footprint of buildings. In collaboration with Swiss universities, the unique «rod technology» was developed for this purpose and a state-of-the-art plant specially designed for processing hardwood was built.

New technologies and adapted regulations have greatly expanded the possible applications for hardwood in recent years. In the meantime, high-strength structural timber made of beech is used, for example, for multi-story load-bearing structures of high-rise buildings and large spans in industrial and public buildings.

The strong alternative

The rod technology of FAGUS makes it possible to produce a solid construction timber that combines very high strength with the natural aesthetics and ecological advantages of wood. Filigree constructions, extended spans and slender supports can be realised in a fascinating variety, and space and weight are also saved. In some cases, this even eliminates the need to pile the subsoil for the building’s foundation, with corresponding cost savings. The building owner benefits from an improved climate balance of the buildings and the local economy from a higher added value.

The wood is harvested and sawn in the region and processed into finished structural components at FAGUS. The entire production takes place in Switzerland with short transport distances.

Advantages and areas of application of rod laminated wood

The largely automated production of rod-laminated wood set up by FAGUS offers various advantages. For example, maximum product safety is ensured by seamless quality control from material receipt to the finished beam. The highly automated production process also enables rational and cost-effective processing. Thanks to an extensive raw material stock and a short processing time, the qualities and quantities requested by customers are available with short delivery times. In addition, customers’ own wood can also be processed in the factory on request and with the appropriate lead time.

Building with hardwood as an answer to the «green building» megatrend

Various studies confirm the excellent future prospects for timber construction all over the world. Timber construction is the cheapest method of permanently storing CO2 – not to mention the constructive, aesthetic and economic advantages. Institutional and private real estate investors recognise timber construction as a measure to achieving their climate goals. In parallel, the demand for high-strength hardwood construction timber is also steadily increasing. Hardwood is stronger than softwood and lighter than steel and concrete.

Experience from finished projects shows that the use of FAGUS construction timber does not make a building significantly more expensive than a conventional solid construction with steel and concrete. After deconstruction, structural timber can either be reused as construction timber or recycled as energy wood in appropriate plants.

Projects with FAGUS construction timber

1 Office extension of Holzkraftwerk Basel AG

With this office extension, a new chapter in modern high-performance timber construction was written. Huge lattice girders, made of FAGUS rod-laminated beech, span a static length of 35 m. The high tensile and compressive strength of the beech is the basis for the high performance timber construction. Thanks to the high tensile and compressive strength of the rod-laminated beech, the trusses appear extremely filigree despite their enormous dimensions.

2 «Clime» building of the Grosspeter development in Basel.

In the five-storey office building in Basel, 34 FAGUS high-performance columns made of Swiss ash wood were installed on the ground floor. The decisive factors for the choice of laminated rod timber were the slim, space-saving design and the beautiful hardwood appearance of the ash wood.

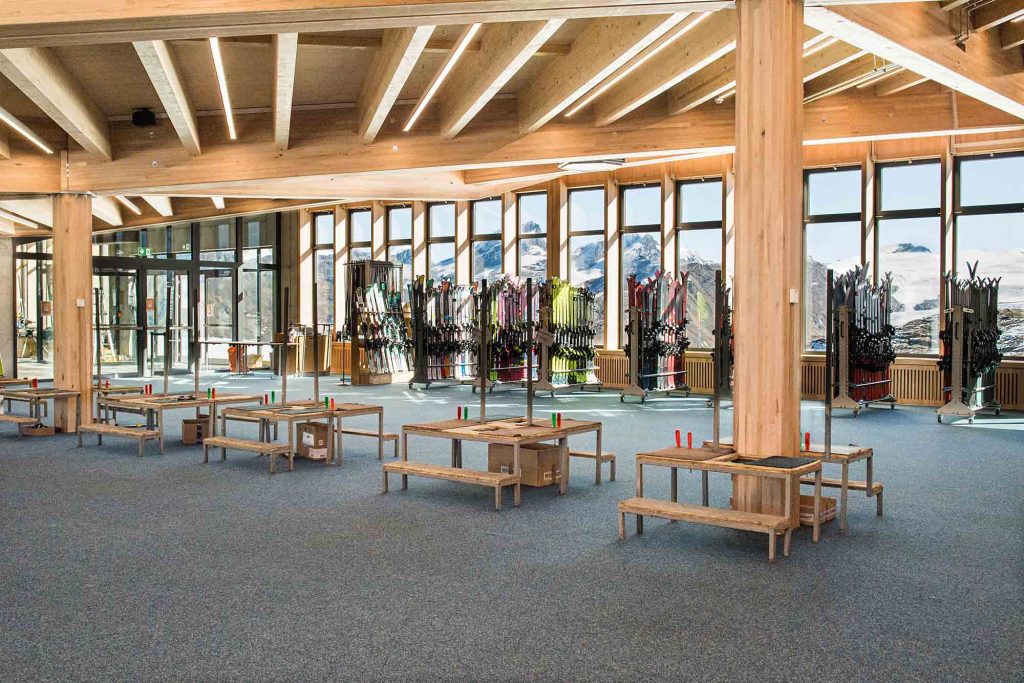

3 Zermatt Ski Test Centre at 2,939 m above sea level

FAGUS rod-laminated beech was used for the new construction of the Stöckli Skitest Centre on Trockener Steg in Zermatt. With the enormous snow loads in the high mountains, the strong beech wood can show off all its advantages and enables a slim and light construction. This also means less weight to transport, which simplifies logistics, especially in the mountains.

FAGUS SUISSE

Grand’Rue 21, CH-2345 Les Breuleux, Switzerland

Tel. +41 32 474 45 35

info@fagussuisse.ch / www.fagussuisse.ch