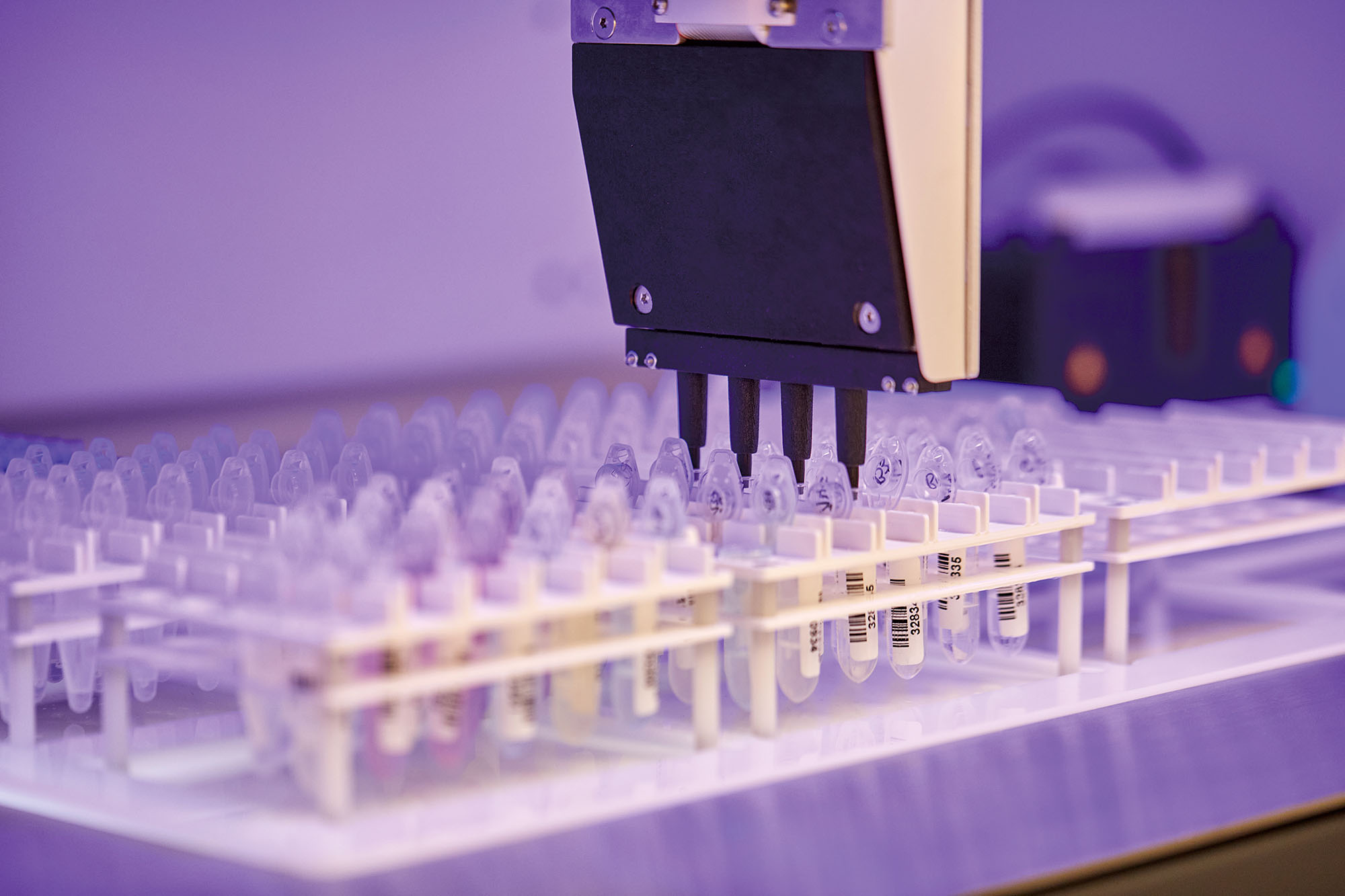

Flow Robotics is a Denmark based vendor of robots for automated liquid handling. The robot, flowbot ONE, performs liquid handling tasks in the laboratory and takes over many of the repetitive and burdensome manual pipetting tasks.

“Manual pipetting is a large part of liquid handling in a laboratory. That means repetitive work for hours and hours, often in a fixed position, and the result is strain to especially shoulders, arms and hands,” says Morten Sunesen, CCO at Flow Robotics.

Unlike other lab robots, the flowbot ONE does not require programming skills and can be used by anyone. Robot technology minimizes the risk of human errors in the liquid handling process, and increases reproducibility of experiments to the benefit for laboratory personnel around the world. Besides this an automated liquid handler allows lab personnel to engage in other more valuable activities increasing the productivity of the lab in general.

“Now, the sclerosis patients get answers 30 % faster than before. The time from we start the tests until we can conclude on results has been significantly shortened and it is really satisfying to me. We could not have done this without the flowbots.” Senior Lab Technician, Unilabs

With the COVID-19 outbreak, the demand for collecting and preparing virus samples has exploded. Recently, the American Society for Clinical Pathology conducted a survey of laboratory professionals and reported that 85.3% felt burnt out and 31.5% complained of a heavy workload and pressure to complete all testing.

Since May 2020, the focus in Flow Robotics has been on fighting COVID-19 as the flowbot ONE speeds up the analysis of the COVID-19 tests and while it keeps the laboratory assistants safe. Today more than 600,000 COVID-19 tests are being prepared each month on a flowbot ONE.

This year the focus for Flow Robotics has been on improving the robot with integrations to external devices like bar code scanning to ensure full traceability of the processed samples data run on flowbot ONE. Also, temperature control for heating and cooling, a magnetic deck for nucleotide extraction as well as shaker has been integrated into the software for easy programming. We will also in the future plan have more software and hardware updates to expand the possibilities of the robot even more. Our focus is still easy and intuitive while being the most flexible liquid handler robot around.

One of the learnings during the Corona pandemic regarding robotics and automation has been that while end-to-end automation of processes in closed system is very convenient for the users, it is also very vulnerable and only as strong as the weakest link.

For diagnostic labs it has been found that the acceleration of capacity was too slow and too inflexible.

First, the vendors of kits and plasticware are needed for the automation process could not deliver the mission critical consumables and the systems could not be deployed with the consumables available from competitive or alternative vendors. Second, the general availability of the automation systems – the hardware – has also been a real bottleneck.

For all these reasons, we see managers of lab automation in the diagnostic sector globally have learned to have alternative backup systems: Systems that are not closed, are more flexible and automate part of the processes that are more error-prone and manual labor intensive.

Soon, we believe we will see smaller automation systems with great flexibility of input and output that will be more versatile when the capacity needed for screening drop post-corona.

Flow Robotics has placed robots in 13 markets (and counting). USA and Asia are next targets for Flow Robotics in 2021 and forward.

You can read more about Flow Robotics at www.flow-robotics.com.