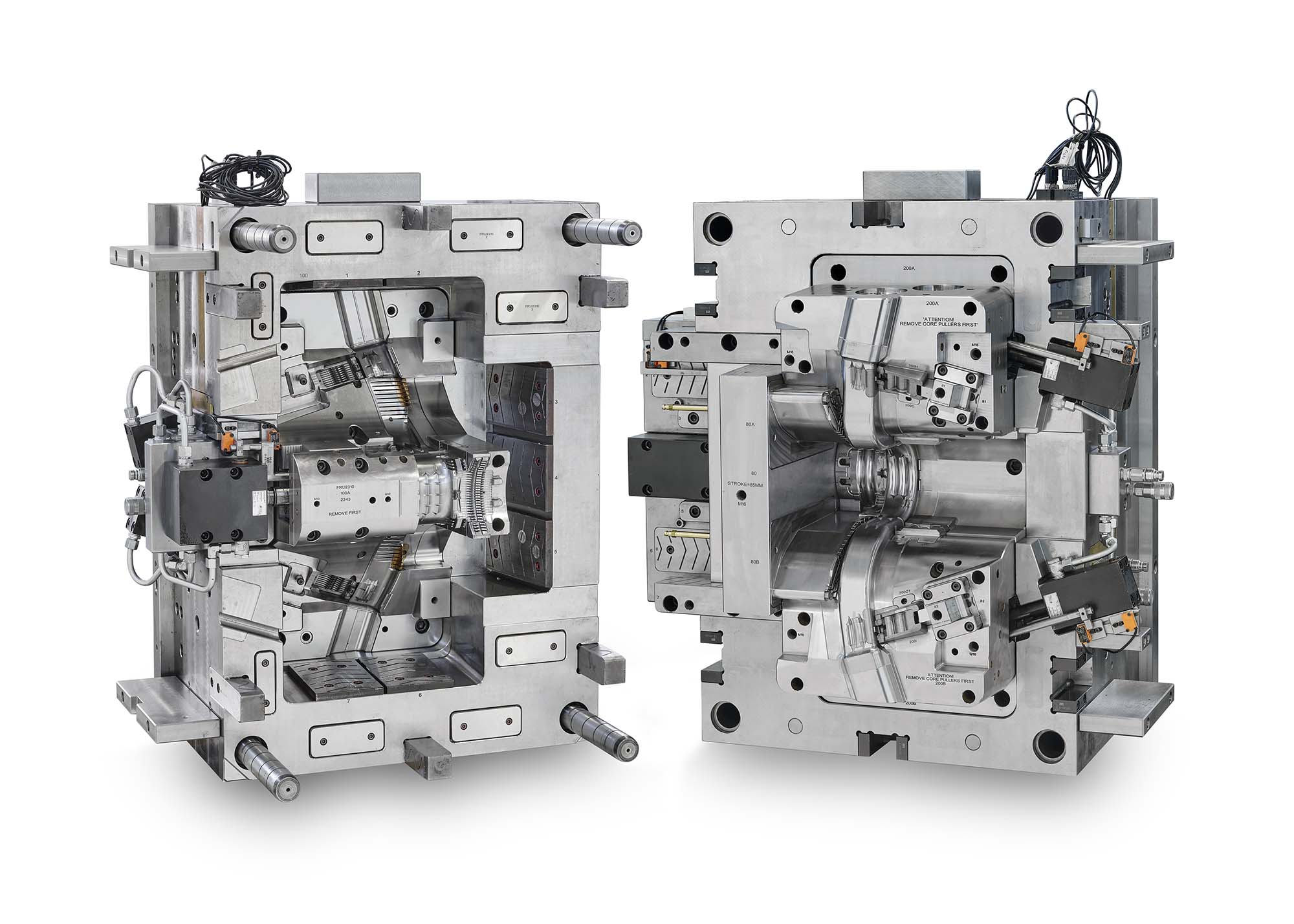

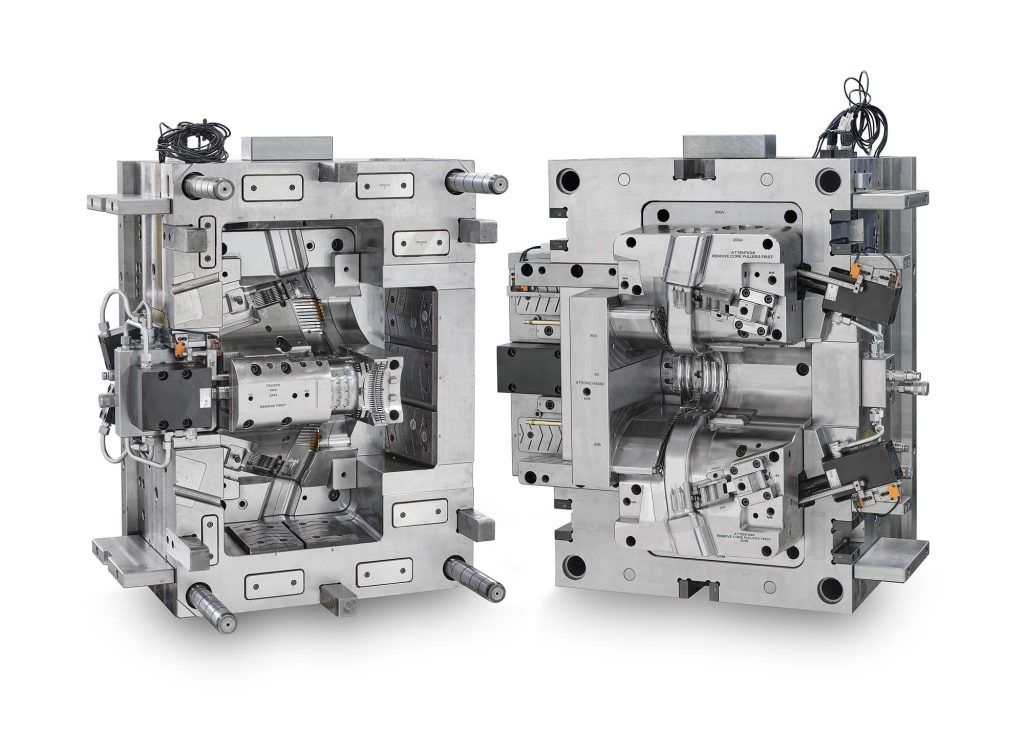

Frumolde Tooling is a leading Portuguese plastic injection mould maker. In the market since 1990, they develop projects from the first idea to the final product. Aware of each client’s needs, the company provides a complete service, starting with the design of technical moulds (for all thermoplastics), carrying out rheological studies modelling, programming, and manufacturing moulds with the highest technology on the market.

Interview with Mário Frutuoso, CEO of Frumolde Tooling.

Easy Engineering: What are the main areas of activity of the company?

Mário Frutuoso: We are an injection mould supplier mainly for the automotive industry, medical and scientific segments, household appliances and electronic markets.

E.E: What’s the news about the company?

M.F: We are currently upgrading our production capacity and moving to the Industry 4.0 level, which focus on the intelligent and interconnected use of advanced technologies. New 5-axis CNC machines and an automated electrode cell will give us the skills and solutions to increase productivity and enable us to make decisions in real time and from anywhere.

In line with a strong environmental commitment, we also updated some processes and applied solar panels on our entire roof-top to become more sustainable

E.E: What are the ranges of products?

M.F: We are specialized in technical moulds with a production capacity up to 10 tons. We are also expertise in moulds with metal Inserts, 2K/3K and High Polished surfaces.

E.E: At what stage is the market where you are currently active?

M.F: Moulds industry is a very competitive market that requires us to be always at the forefront, both in technological terms and in terms of interaction with customers.

To create long-lasting and trusting partnerships with actual and potential customers, we make regular visits and participate in trade fairs and business missions all over the world. This way, we get a better knowledge of the market to provide an appropriate response to customer´s requirements.

E.E: What can you tell us about market trends?

M.F: One of the largest and most demanding market for the mould makers is the automotive industry. This market continues in transition to zero emissions, which leads to new designs, technologies and materials that create new challenges to the suppliers. So far, it’s being very interesting participate in this new era.

At the same time, we’re also being challenged by the innovations in the medical, electronics and construction markets. The Key factor to able us be capable to work for all these demanding markets is to have a dynamic and skilled team.

E.E: What estimations do you have for 2023?

M.F: Frumolde Tooling is confident in sales growth when compared to 2022 results.

We aim to continue to develop the company in line with markets trends by investing on technology, processes and employee’s qualification.

We believe those combined factors are the success keys to achieve our goals.