Gantrex is the global market leader in production, distribution, installation and maintenance of high quality crane rail solutions and crane parts. Gantrex’ products are used in many different applications and end-markets including ports, shipyards, steel mills, aluminum smelters, railway depots and heavy industries.

Easy Engineering: A brief description of the company and its activities.

GANTREX: Gantrex history started in 1971 in a small office in Nivelles, Belgium, and has since grown into an international company with Sales & Service Centers in 20 countries on 5 continents.

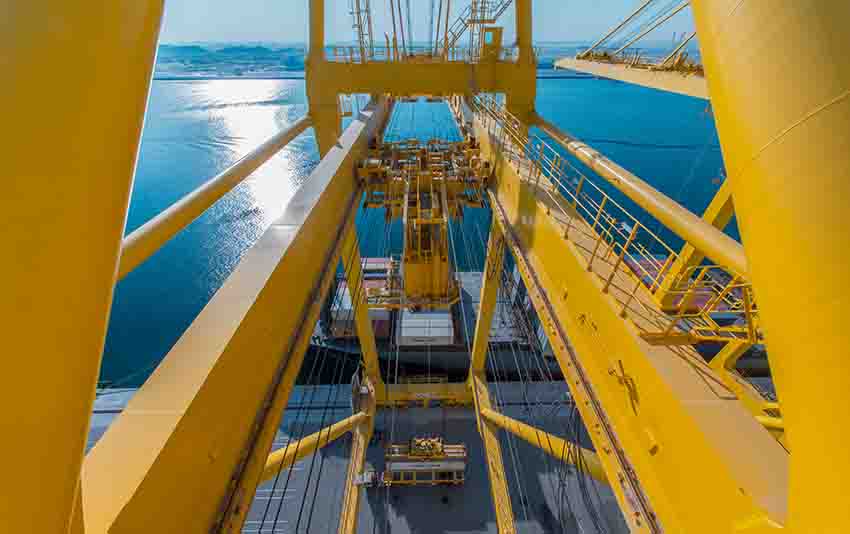

We are now in the process of expanding our service offering to include parts and services for the full crane. Since 2015 we have been providing our customers in Europe with diagnostic and repair services for their Ship-to-Shore and Yard Cranes while also supplying most of the parts required to complete such repairs.

E.E: What are the ranges of products?

GANTREX: We are currently in the process of rolling out our Crane Diagnostics and Repair Services and Supply of Crane Parts throughout the world. Our Engineers in Europe and Middle East have decades of experience assembling and repairing cranes and have the latest diagnostic tools at their disposal, such as 3D scanning and Vibration Analysis, to complete root cause analysis and health checks on any Quay or Yard Crane.

We are also building on our experience in Europe and now supply Mechanical Crane Parts, such as Crane Wheels and Wheel Assemblies, Sheaves, Rollers, Drums, Head Blocks, Twist Locks and other parts, on all 5 continents.

Another extremely innovative product that was launched within the last 5 years is our Gantrex HingeGuard™ Short Rail which is now installed on 13 cranes around the world. This is a game changing product that increases the comfort of crane drivers as the trolley passes over the hinge joint of Ship-to-Shore cranes while reducing the required maintenance and minimizing the transfer of shocks, vibration and noise to the crane.

E.E: What are the most innovative products marketed?

GANTREX: Our Crane Diagnostic services are definitely trending, we are already well known for our specialization in crane rail systems and now we couple that with our knowledge of cranes. A recent example comes to mind where a customer had an issue with trolley rail wearing out too quickly on one of his Ship-to-Shore cranes, after a visit to site, our technician noticed that not only the rail was wearing out but also a wheel on the trolley had substantial flange wear. To understand the issue our engineers completed full diagnostic on the crane with the use of a 3D scanner. This allowed us to see not only the rail but the full boom, girder, and trolley structures, and how the trolley would interact with the rail. The deliverable of the diagnostic was a report to the customer with a root cause analysis, repair recommendations and a budget to complete such repair. Understanding that the wear on the rail is just a symptom of a larger problem is extremely important in providing accurate solutions for our customers.

The most innovative product in our arsenal is the Gantrex HingeGuard™ Short Rail which is a self-damping short rail solution designed to support the trolley track constraints, and reduce vibration, shocks and rail wear.

The unique characteristic of this patented innovative solution is the extension of the soft mounting features, that are normally present under the trolley rail, to the hinge joint. We achieve this by vulcanizing a rubber layer inside the Short Rail which acts as a dampener of shocks, vibration and noise.

This is a complete tailor-made system, it can be completely adapted to the needs of each individual installation. It fits all ship-to-shore cranes, can be installed with no additional impact on installation time, and delivers substantial noise and vibration reduction.

E.E: What’s the importance of these features for the users in their work?

GANTREX: Understanding and repairing the root cause of a problem is extremely important, if we keep repairing the symptoms without tackling the root cause then the same issues will keep recurring, which will require to take the crane out of service for maintenance and repairs not only costing our customers additional funds to fix the recurring problem but also lost of income due to crane outages.

When it comes to our Gantrex HingeGuard™ Short Rail the dampening of shocks, vibration and noise is very important especially for the Crane Drivers that have to operate the cranes throughout their workday moving over 30 containers each hour. If the short rail area is slightly misaligned or worn it causes substantial shocks and vibrations in the cabin. These shocks become very noticeable especially when the crane driver has to go over the hinge area 60 times every hour, or once every minute. Reducing these shocks to within acceptable levels increase the well-being of the operators.

Reducing the shocks and vibrations on the trolley and crane also increases the longevity of the electrical equipment that is installed on the cranes and the trolleys. The smarter the cranes the more sensors are installed throughout the crane and especially the trolley. Shock and vibration can have a severe effect on these sensors, hence reducing the shock and vibration from the Hinge Joint would in turn reduce the amount of maintenance required on the sensors.

E.E: How do your new products / services differ from others on the market?

GANTREX: We can provide our customers with a one stop shop, which means that we are able to diagnose the problem through a visual inspection, 3D scanning and/or vibration analysis, provide all the required materials and complete the necessary repairs.

On top of that we use all the latest diagnostic tools, depending on the issue we need to diagnose we can complete a full 3D scan of the area or the full crane to understand if there any abnormal structural deflections or investigate the dynamic behaviour of the crane through vibrational analysis. Whatever the problem we should be able to find the solution and provide our customers with a repair plan and budget.

When it comes to our Gantrex HingeGuard™ Short Rail, it is the only patented solution in the market that offers dampening characteristics at the hinge joint area. Current solutions consist of solid steel joint that is installed on a steel wear plate which is then installed directly on the structure. Since this is steel-to-steel contact all the vibration and shock from a wheel passing over the discontinuity is transferred directly into the crane and driver cabin. Installing a rubber layer within the rail dampens these shocks and vibrations. Based on the latest independent studies we saw a 2.5 times reduction in shocks and 40% reduction in vibrations when our Gantrex HingeGuard™ Short Rail was installed on a crane in Europe.

E.E: Tell us about Gantrex’s research and development.

GANTREX: We have an innovation committee which is managed by the Group Innovation Manager who works very closely with both the Commercial and Technical departments.

A lot of our innovation comes from direct requests from the market where customers share their frustrations or wish lists. Having over 20 offices around the world keeps us very close to our customers and especially their issues, we always do our best to listen to what these customers tell us and the problems they are having. These problems present great opportunities for new products or service lines which we are always eager to explore.

Our Group Innovation Manager is always extremely busy testing different products and services before we release them to the market. A good example is the Gantrex HingeGuard™ Short Rail, before it was officially launched into the market it went through vigorous testing, the first prototypes were analyzed and tested on site, the design was then improved and cyclically tested in the lab under extreme conditions to ensure the improvements were able to withstand the dynamic forces the Ship-to-Shore cranes are subjected to.

E.E: What’s the impact of product innovation on your customers?

We normally work very closely with our customers on identifying their needs and developing products that solve real life problems, hence when new products are developed our customers are very happy to test them at their facilities so we can learn and improve on our products. This type of approach creates innovation synergies between us and our customers.

E.E: What new products / solutions are you going to launch in the future

GANTREX: There are a few digital products and services that we are currently working on to improve our customers’ journey. We are also planning innovation seminars and roundtables with our customers to get further feedback on what needs and pains our customers have, to see if we can develop products to accommodate.

E.E: What estimations do you have for 2024?

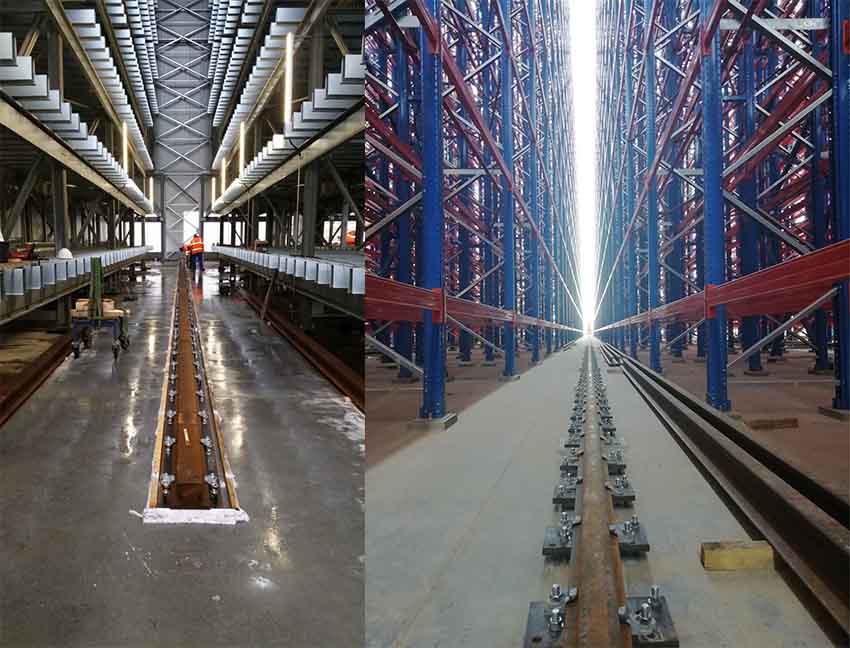

GANTREX: Green energy and the change to electric transportation methods are two sectors that we need to keep an eye on. Automated Warehousing is always a growing sector due to space limitations. Shipment of goods through ports and terminals is also a growing sector that keeps us very busy.

The products/solutions we provide for these industries

We are heavily involved in the ground and overhead rail tracks in all production facilities of wind turbines and solar panels. We are also involved in providing both products and services for the Warehousing industry where we supply and install all the necessary rails systems and now also get involved in the installation of the vertical racks. With regards to ports and terminals, we are heavily involved in all stages. During construction we supply and install all the rail systems on both the Quay and Yard and provide rail and short rail systems for the new cranes. Once the terminals are live, we provide support to the maintenance personnel through supply of crane parts, diagnostic services, health checks and repairs.