Founded in 1997, the Gesellschaft für Bild- und Signalverarbeitung (GBS) mbH develops, manufactures and sells optical 3D Sensors, 3D Optical Profilometer, Bridge Measuring Machines and Shop Floor Measuring Stations based on the principle of white-light interferometry (coherence scanning interferometry).

The core know-how – massive parallel image and signal processing on GPGPUs (general purpose graphic processing units) – is used to accelerate measurements of surface structures and micro geometries.

The fast-growing demand on high performance solutions in the area of surface metrology requires an expansion of production capacities. For this reason, GBS will move in the new head quarter end of 2021 and the next expansion step is already in the works.

Why is white-light interferometry the proper measuring principle for your sensors and measuring systems?

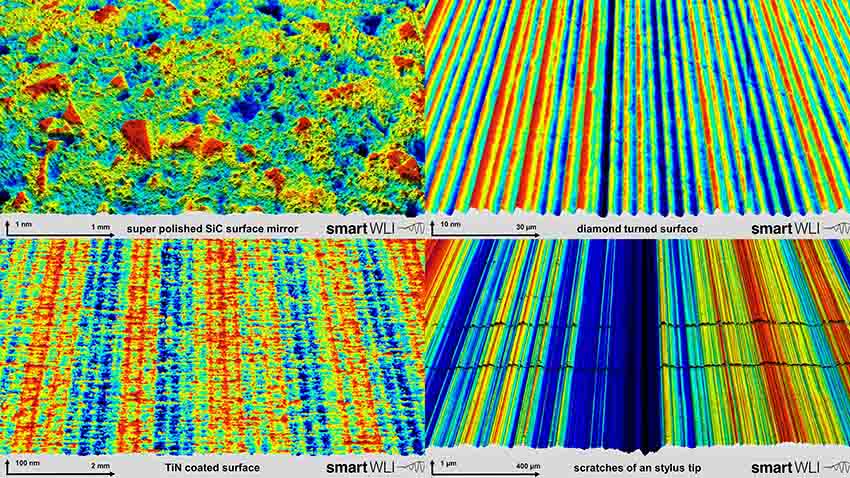

Once you want to measure surface roughness and micro geometries, white-light interferometry provides the highest height resolution compared to other optical measuring principles like focus variation or confocal microscopy. You can even scan nanostructure with sub nanometre resolution. Best of all – in contrary to the other measuring principle, you have the same extreme height resolution independent of the objective magnification.

What surface type does your customer measure using your sensors and measuring systems?

The systems can measure many different surfaces. There is hardly no limitation for surface types: rough metallic surfaces, nearly perfect mirrors, structured semiconductors to transparent optics.

As you can see our 3d scans show smallest details without the risk of damaging the surfaces. The Z scan range goes up to several mm and depending on the required magnification we can scan areas of several cm².

What are the recent activities of GBS?

Currently, there is a high demand for integrating high performance sensors into automated measuring stations and production lines. This integration requires custom tailored software interfaces as well as 100% reliable products running without failures over months. For this reason, we are hiring software engineers to boost the internal quality control and objective system tests.

Which are the most interesting markets this year?

Semiconductors, electronics and optics are definitely the most interesting branches. The growing investments in these markets may overcompensate the relative weak prospect of the automotive industry. For instance, the surveillance of processes in wafer polishing and wafer structuring demands for extreme resolution of our sensors as well as the speed. The common saying “Time is money” is really important if huge amounts of measuring positions on wafers have to be inspected to ensure that the production processes are running optimally.

What are the bestsellers in your product portfolio and what the reason for the success?

Long-time bestseller is the smartWLI compact with an excellent price-performance ratio. It is utilized as main component for lab measuring systems as well as integrated in production lines for specific measuring tasks. The sensor is easy to use and the compact dimension as well as the moderate weight simplifies the integration in product lines. If switching between various magnifications becomes necessary, the smartWLI next is the second most sold sensor. The motorized turret for up to four objectives makes this system highly flexibility. Most often it is utilized in automated wafer control stations with proven success.

What innovations can your customers expect from GBS in 2022?

Further accelerating the scanning speed – we just introduced the smartWLI firebolt with uses a GigE10 camera with 935 frames per second (FPS) for full area scans. Using subsampling or a reduced area of interest, the frame rate may go up to over 10000 FPS. Speed is not witchcraft and such frame rates can “freeze” the impact of vibrations. Vibrations are a big challenge especially for sensors mounted on robots for roughness measurements or inline sensor installation for measure nanostructures. A single µm is small and a nm is even smaller by a factor of 1000. Vibrations may have a significant amplitude and vibration isolation systems are expensive but oftentimes can’t be used in production lines. For this reason, increasing the scan speed combined with advanced evaluation algorithms is the only possible way to avoid or at least dramatically reduce the impact of the vibrations for the measuring process.

Which trends do you expect in the future?

Many customers want to integrate the quality control direct into production lines. Security or functional critical parts already require 100% control. Manual inspection in a measuring lab with its time delay costs money and inheres the risk of delaying the adjustment of process parameters – but this is still the standard if the control of the surface roughness is necessary. Running machines and handling systems which cause vibrations have made it impossible to use conventional optical high-resolution sensors in such areas. High speed sensors with several thousand FPS will be the game changer and robust enough to be used under such conditions.

GBS

Matthias Liedmann: matthias.liedmann@gbs-ilmenau.de / (https://www.linkedin.com/in/matthias-liedmann/detail/recent-activity/shares/)