Granutools is a Belgian company that specializes in the development and manufacturing of advanced laboratory and industrial instruments for characterizing the behavior of powders. The company aims to provide precise and repeatable measurement techniques for powders and offers a range of instruments and services to assist industries in powder handling and processing.

Interview with Filip Francqui, Managing Director at Granutools.

Easy Engineering: A brief description of the company and its activities.

Filip Francqui: The founders of Granutools, Filip Francqui and Geoffroy Lumay, established the company with the mission to bridge the gap between expensive shear cell systems and manual devices. Their goal was to meet the industrial demand for accurate and operator-independent instruments with clear physical knowledge.

Granutools takes pride in having a dedicated team that is committed to understanding and meeting the specific needs of each customer. With their expertise and customer-centric approach, the company aims to provide valuable solutions to various industries using powder in their process.

E.E: What are the main areas of activity of the company?

F.F: The main areas of activity for Granutools revolve around powder characterization and testing. They focus on providing instruments and expertise to industries that deal with powder manipulation, such as the additive manufacturing (3D printing for example) industry, the pharmaceutical industry, and the battery manufacturing industry.

E.E: What’s the news about new products? What are the ranges of products?

F.F: Granutools has a set of five instruments. These complementary tools address specific challenges in powder analysis.

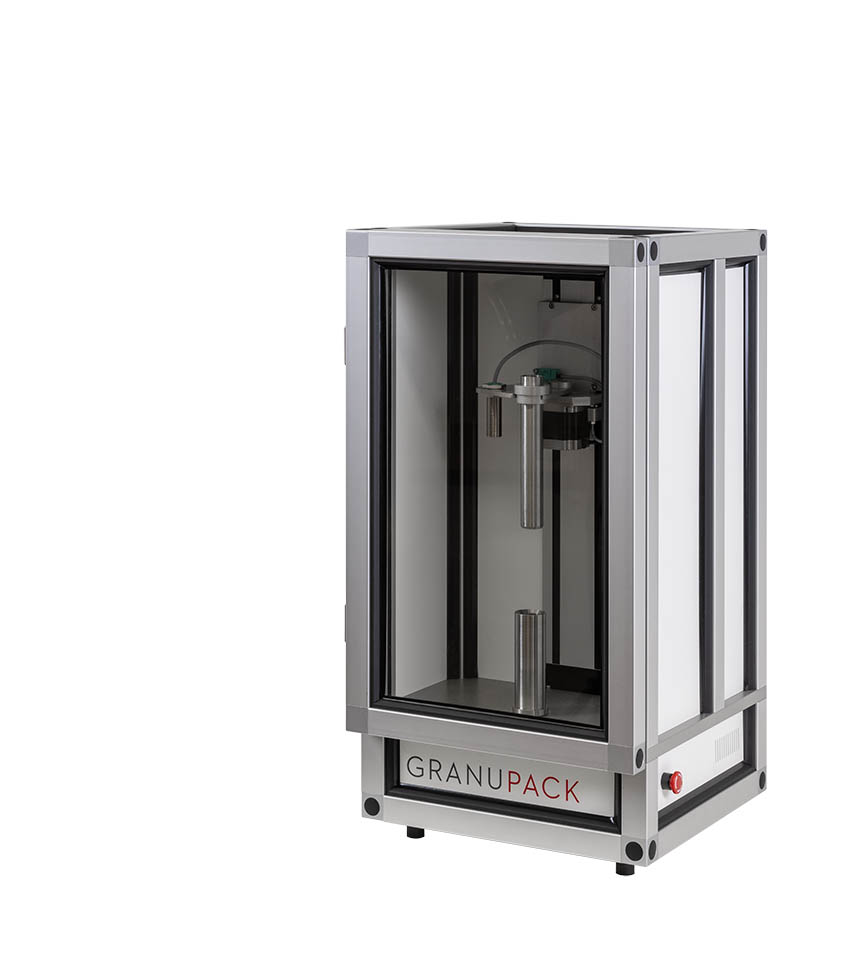

The GranuFlow measures powder vertical flow rate, GranuHeap automates angle of repose and static cohesion measurements, GranuDrum assesses cohesive index and dynamic angle of repose, GranuPack measures tapped density and packing dynamics, and GranuCharge quantifies electrostatic charges before and after powder flow through pipes.

In addition to these instruments, Granutools is actively developing software tools to assist both industry and academia in better understanding their powders.

Furthermore, Granutools is excited to announce the upcoming launch of the GranuPack Permeability instrument. This innovative instrument features a specially designed measurement cell for evaluating powder permeability. The ability of air to pass through a powder is critical in various applications such as silo operations, tableting processes, and dry powder inhalers. By measuring air flow velocity and pressure drop, the GranuPack Permeability instrument will enable the assessment of powder permeability. This new addition to Granutools’ product line will provide a versatile solution for measuring physical parameters related to powder packing dynamics and fluidization.

E.E: At what stage is the market where you are currently active?

F.F: The global additive manufacturing market size is expected to grow. Factors driving the growth include increasing demand for prototyping applications in industries like healthcare, automotive, and aerospace & defense, as well as aggressive research and development in 3D printing. The industrial 3D printer segment dominates the market, while desktop printers are gaining traction. The market is primarily driven by prototyping applications, and the automotive sector holds the largest market share. North America is the leading region, followed by Europe, while Asia Pacific is expected to experience significant growth.

The battery manufacturing industry is also experiencing rapid growth as the demand for sustainable energy solutions increases. In this competitive landscape, battery manufacturers face immense pressure to enhance battery performance and lower costs. As different powders are used in electrode production with varying flow properties, which directly impact manufacturing processes and electrode performance, powder characterization is crucial.

Similar growth is also being experienced in other industries where Granutools operates.

E.E: What are the most innovative products marketed?

F.F: Granutools stands out as an innovative company due to its unique approach and cutting-edge products. All our instruments are designed with innovation in mind and undergo continuous improvement processes. Take, for instance, the GranuHeap, which is the only instrument in the market capable of performing a comprehensive 360-degree analysis. This exemplifies our commitment to pushing the boundaries of what is possible in particle analysis. In terms of market competitiveness, our instruments lead the pack in terms of advancement, offering the most sophisticated features and capabilities.

To further cater to our customers’ needs, we regularly release new software updates every 18 months for each instrument, taking into account valuable customer feedback and market demands. This allows us to adapt and refine our products to ensure they remain at the forefront of technological innovation.

When it comes to instrument development, our focus is on achieving high repeatability, precision, and operator-independence. We employ strict initialization protocols and integrate a high level of automation into our instruments, ensuring consistent and reliable results. By prioritizing these qualities, we enable our customers to have full confidence in the accuracy and consistency of their particle analysis processes.

In addition to our innovative products, Granutools adopts a consultative sales approach, demonstrating our commitment to customer satisfaction. We work closely with our customers, helping them understand and address the specific challenges they face. As a customer-centric company, our primary goal is to support our customers’ efforts in research and development as well as in the production and handling of powders. By providing personalized guidance and tailored solutions, we empower our customers to achieve optimal outcomes in their respective fields.

Granutools’ innovative approach, advanced instruments, responsive software updates, and consultative sales philosophy position us as a leading partner for those involved in the study and manipulation of powders.

E.E: What estimations do you have for 2023?

F.F: Predictions for 2023 are inherently uncertain, as the past few years have demonstrated the difficulty of accurately forecasting global events. However, despite these challenges, our company has made significant strides. During the COVID-19 period, we utilized the time to develop a new product, which has been well-received in the market.

Over the past six months, there has been a notable increase in demand for powder characterization, marking a positive trend for our company. This sustained growth reflects the value and relevance of our offerings in the market. Moreover, there continues to be a strong interest from companies involved in energy and battery manufacturing, indicating potential opportunities for further expansion.

As always, it is essential to stay agile, monitor market dynamics, and adapt our strategies accordingly to leverage emerging opportunities. While we cannot definitively predict what the future holds, we remain confident in our solution and are optimistic for our company in 2023.