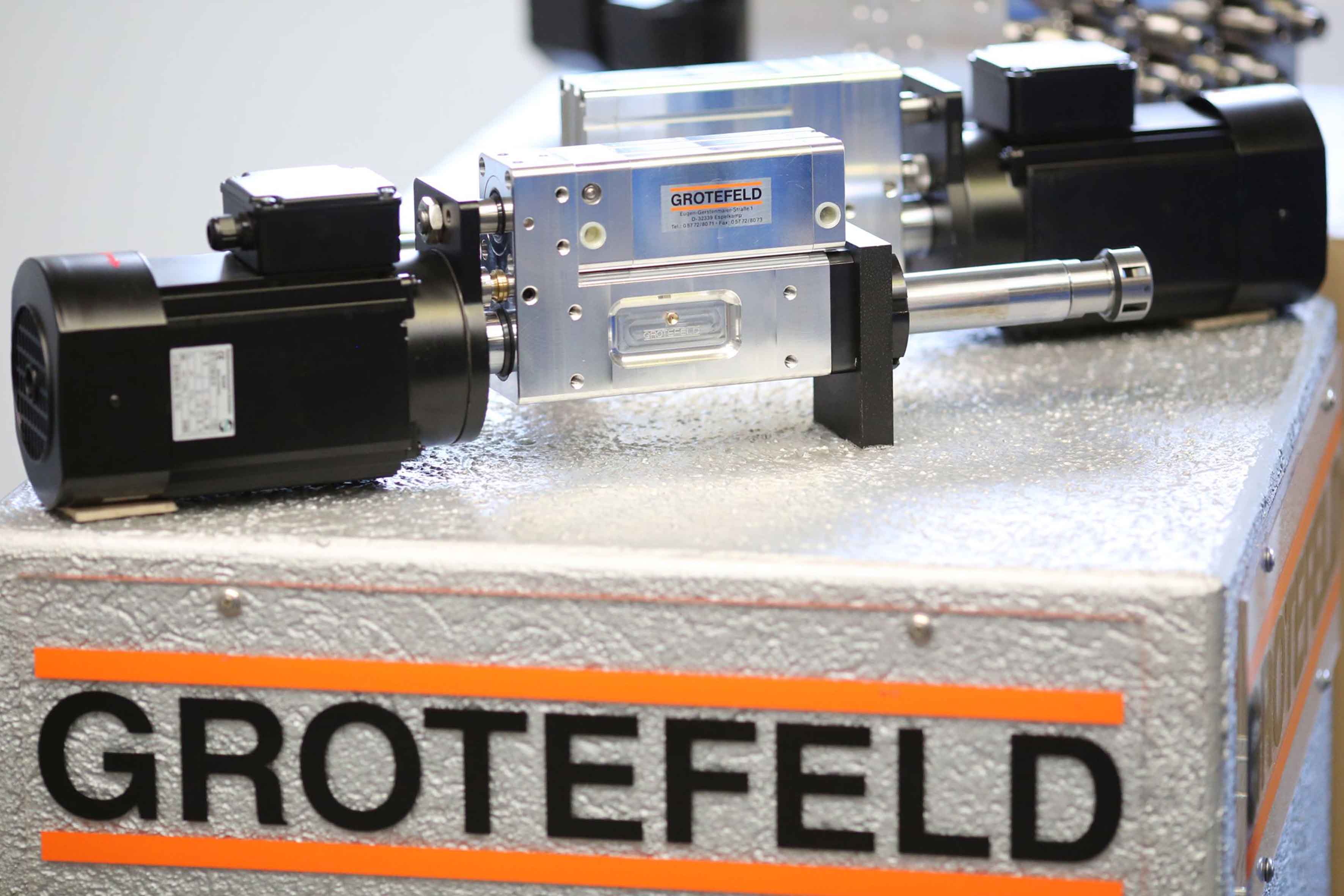

The system supplier Grotefeld GmbH from Espelkamp is a highly specialised premium producer of process-oriented power unit technology. The company constantly applies itself to developing new applications in terms of materials – from plastics and metal to mineral-based construction materials through to composites or biopolymers. The company, which is based in northern part of Germany, has fully embraced this year’s motto of the LIGNA “Processing of Plastics and Composites” (PPC) by gearing its presentation at Ligna towards its own high-precision units, which are able to withstand stress over a long period of time, for the processing of interesting and unusual materials.

Targeted further developments for special applications

The company demonstrated the drilling of gypsum-cement panels with controllable drilling gears. Although this may sound a simple task, a substantial amount of time and effort is actually put into the development on closer inspection. The highly abrasive dust mixed with the moisture in the air causes considerable problems for both the stability of the unit and the guarantee of long-term, trouble-free operation.

These issues have been completely resolved by Grotefeld in a constructive manner and by using specially selected materials for the tools. First-class solutions are achieved in this particular application with features including new wipers and seals/gaskets and by making use of pre-existing physical characteristics. This thus ensures three-shift operations without any interruptions, for example in the drilling of concrete acoustic tiles for sound protection on motorways.

What is right for concrete can be wrong for plastics

Although the machining of glass and carbon fibre reinforced plastics (GRP and CRP respectively) is entirely different, their processing is by no means less demanding. Grotefeld offers special, smart machining solutions both from a technological point of view and in terms of health-related aspects.

The company has set itself the standard of “only the best is good enough” and its operations are always in line with this aspiration. This is demonstrated by means of extensive detailed solutions. For instance in the case of the processing of CRP: The heavy-duty, lightweight carbon is electrically conductive and thus causes a high degree of corrosion on the machining tools and power units. What is thus very welcome in electrical engineering requires additional time and effort when it comes to finding solutions from the point of view of machining.

The diversity of the properties of plastics fundamentally necessitates extensive development work in the field of premium power unit technology. Although high torque values are mostly required for the machining of such materials, the frictional heat generated by the tool can bring about the deformation of many plastics – and in some cases even cause them to melt.