Hengelhoef Concrete Joints, located in Belgium, is a specialized producer of expansion joints for concrete industrial floors with worldwide projects. In their searching to develop the perfect expansion joint, they introduced a completely new jointing solution (EP 2729619 worldwide extending) which is realizing the best load transfer system ever. The Cosinus Slide® joint has combined the Sinus Slide® solution (EP 2930269 continuous support for passing wheels which enables vibration– and shock free crossings) with an unique technology of load bearing capacity of the floor without any dowel system.

“When I was informed about the opportunity of an article in Easy Engineering Magazine, it didn’t take me long to decide to publish. Indeed, HCJ is convinced that it has a strong message for everybody who is involved in designing, building and using industrial concrete floors for warehouses, distribution centres and other logistic platforms “, says Albert Klingeleers – CEO & Founder Hengelhoef Concrete Joints.

Easy Engineering: A brief description of the company and its activities.

Albert Klingeleers: HCJ located in Belgium – EC is a specialized producer of expansion joints for concrete industrial floors and have been involved in worldwide projects for more than 30 years. The growth and development of HCJ is characterized by our never-ending search and hunger for innovative jointing solutions and new technologies for concrete industrial floors.

E.E: What are the main areas of activity of the company?

A.K: Our company is a reputable trendsetter and market innovator in jointing solutions for concrete industrial floors.

E.E: What are the most innovative products marketed?

A.K: Our company evolved, changed and developed the concrete flooring market from saw cuts to the ultimate Cosinus Slide® jointing solution.

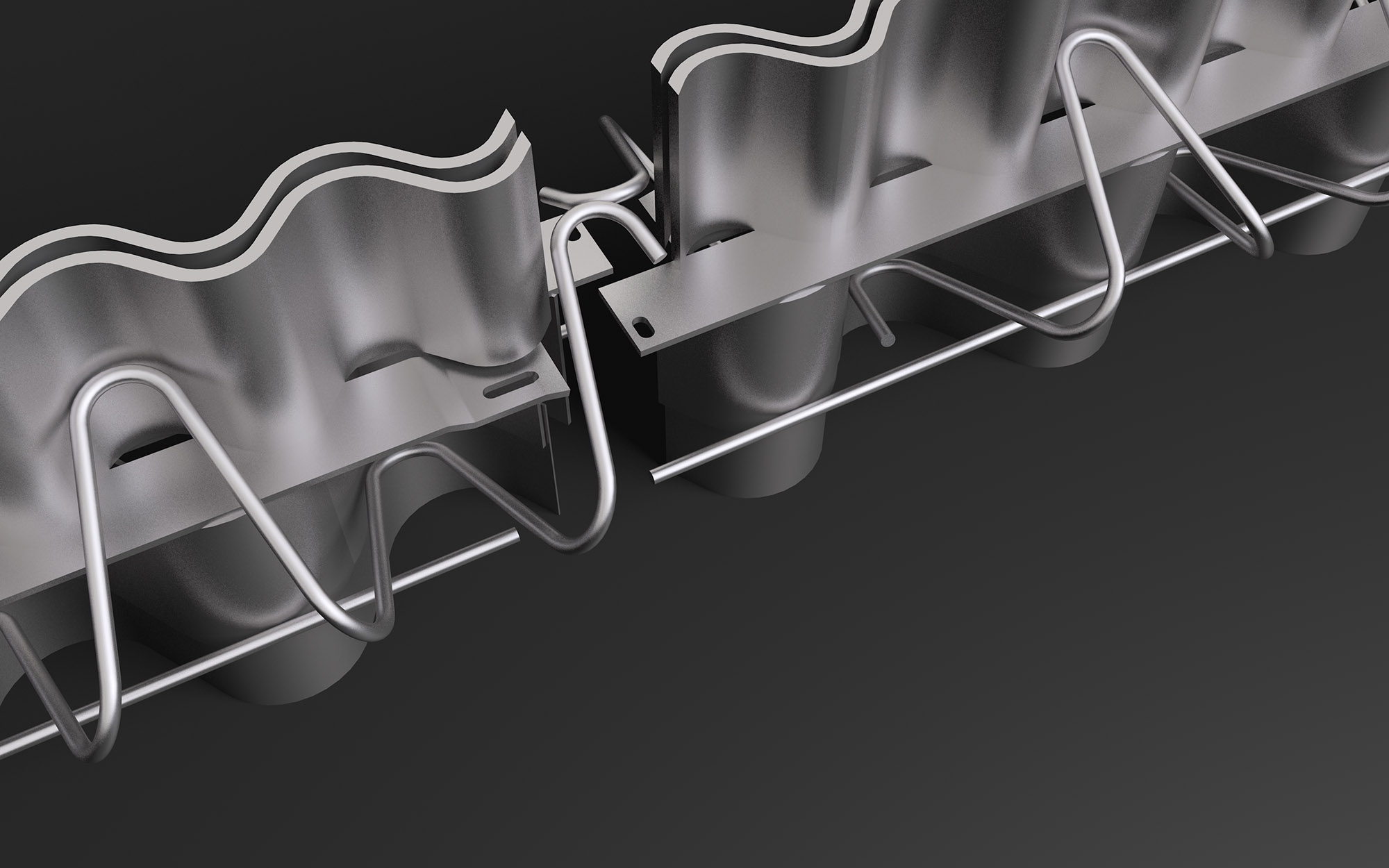

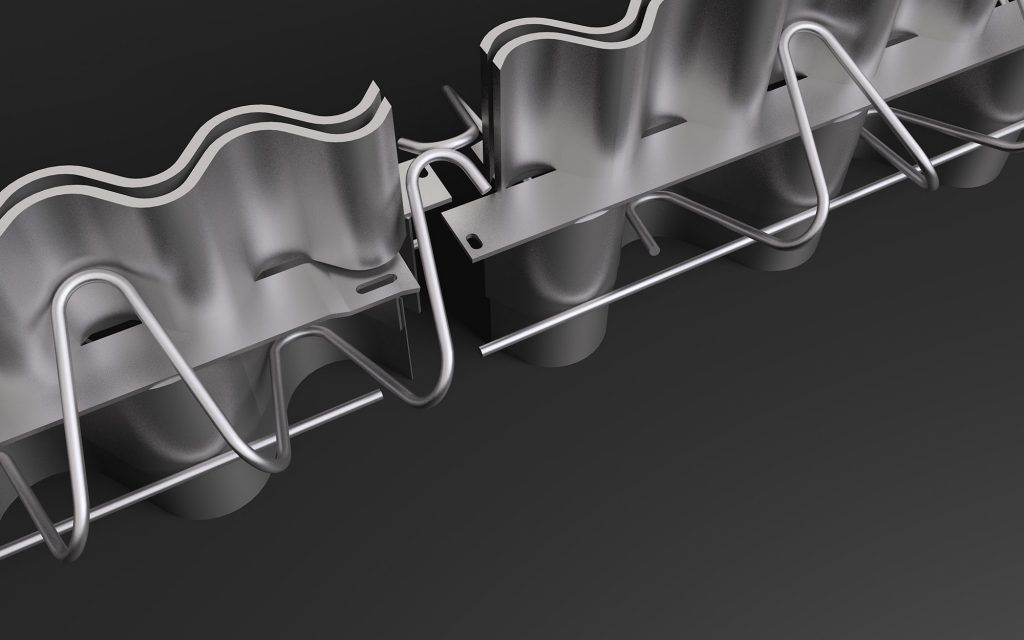

The cosinus Slide® is a unique product characterized by a stable double 2×5 mm Sinus steel plate on top opposed by a double Sinus steel plate on bottom. Instead of traditional anchor studs the joint is fixed in the concrete by a special wreathed continuous rebar system over the total length of the joint and with connections top and bottom. A small steel plate in the middle prevents overflowing of the concrete.

Thanks to the Sinus-Cosinus geometrical shaped form of the joint and the concrete, load transfer is not realized by the joint (like traditional dowel systems) but by the floor itself. That’s why we say; the joint is the floor, the floor is the joint. Each sinus corrugation on top (first slide effect) is opposed by a Cosinus corrugation (second slide effect) underneath. These crossed sinus corrugated steel plates shape small vertical steel concrete columns over each other. The load bearing of these columns defines the load bearing capacity of the complete floor.

This load bearing capacity is very important for the functionality of the joint in particular and for the whole floor in general.

Let me explain it briefly.

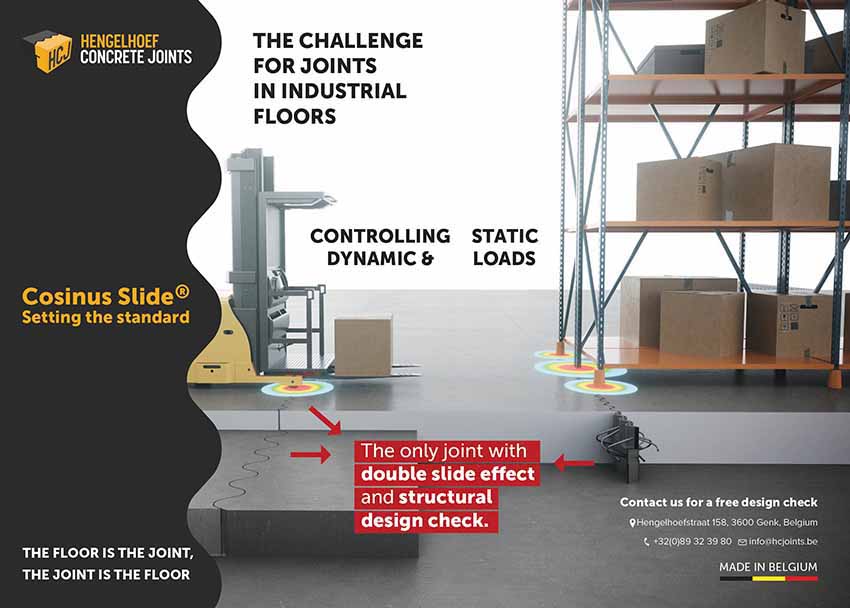

Each joint in an industrial floor must (after shrinkage of the concrete) fulfil 2 functions; namely controlling dynamic and static loads.

Dynamic loads you can only control with a sinus joint. In this challenge, Cosinus Slide® joint is simply the best thanks to its double slide effect. The dynamic loads (forklifts) are transferred simultaneously and proportionally over (first slide effect) and throughout (second slide effect) the floor by those vertical Concrete Columns shaped and supported by the Sinus-Cosinus geometry. Traditional joints still struggle with the striking impact of wheels falling into the opening gap. Even the strongest reinforced joints cannot avoid this very uncomfortable and unsafe situation, which will quickly result in damages. Inevitably, the floor will have a limited use, ongoing suitability and durability. With the Cosinus Slide® joint, the wheels and loads are sliding smoothly and shock free with this unique double slide effect from one floor slab to another without traditional dowel connection.

Controlling static loads needs to be covered with a design check. In most SFRC (Steel fibre reinforced Concrete) calculations fibre producers presume a load transfer capacity of the joint of 40%. However, this 40% is an assumption. Indeed, a widely accepted dogma in SFRC design.

Unfortunately, most dowel based joints cannot perform a load transfer capacity of 40%. Often, they perform poor with load transfer of 25% or even less, where the Cosinus Slide® joint can perform to almost the maximum of 50%.

This huge different in performance is translated for client in multiple advantages like:

- Possibility to optimize the floor in line with the deontological rules of a designer;

- No limitations in positioning the racking systems;

- The experience of a seamless floor for less money.

The Cosinus Slide® joint is the first jointing solution that opens the discussion of Static load transfer. In fact, incorporating the real performance of the joint in an industrial floor design was the missing link. For this reason, we have launched in 2020 our load Transfer Performance Calculator to check the performance of the joint. https://www.designer.hcjoints.eu/login

With its Load Transfer Performance Calculator HCJ is expected to significantly reduce the occurrence of wrongly selected joints. At the very least, we expect flooring engineers to take more conscious and fact-based decisions, safeguarding them from professional risk and keep them in line with their deontological code.

The combination of the Cosinus Slide® flooring concept and the load transfer performance calculator was the missing link in contemporary industrial concrete flooring design.

HCJ is always available to help should you need further support to perform complete and detailed calculations to check and define the best jointing solution.

Summarized we can say that the Cosinus Slide® joint is controlling the dynamic and static load transfer in an industrial concrete floor in the most effective way. This jointing concept makes the investment more comfortable, ergonomic, economical and in line with the calculation rules for the designer.

E.E: Why is a joint so important and how to select the right joint?

Having been at the forefront of joint innovation and development from the beginning, we have observed with alarm that up to 75% of all flooring projects are installed with incorrect and inadequate joints.

This wrong selection may result in TR-34 non-compliance, expensive maintenance and potentially hazardous situations. As an engineering driven company with ground breaking technology in jointing solutions for concrete industrial floors, we found this hard to accept.

Starting from saw cut technology (so called construction joints) in the eighties, we have moved so far forward in 2020 as to show the market how imperative joint load transfer performance and a design check are when executed together.

The performance of the joint is an essential part of each calculation of an industrial concrete floor. But until now, nobody took this into account and it was a missing link in the design.

The choosing of joints that are not fit for the job is often derived from a poor understanding of the dynamic and static load transfer mechanism.

Rules of thumb and experience-based assumptions are no longer good enough to meet today’s flooring requirements. It is crucial that the floor receives proper design and precise calculations.

For this reason, in June 2020, HCJ launched our joint performance calculator, which is a calculation tool to find out the load transfer capacity of a joint. With this, we have bridged the gap to this missing link in industrial floor design.

Flooring design in general, and joint design in particular, is complicated but put simply is nothing more than dealing with two major challenges: controlling dynamic (forklifts) and static loads! (racks)

Our documentation will guide you through this complicated process in a very simple way.

I kindly invite you to visit our website www.hcjoints.be and go through our brochures and videos.

Watch, discover, enjoy and most importantly – let us help you select the right joint for your project.

All this is presented to you with pride and honour because it reflects not only our innovative process but also our never-ending business mission to go for sustainable quality products.