Netherlands-based Dunlop Conveyor Belting have launched a new and totally unique concept in heat resistant conveyor belting, which they claim is the first truly new heat resistant belt construction to be made available to industrial users in decades. Optima Heat Xtreme is a revolutionary single-ply high heat resistant belt that has been developed in cooperation with their colleagues in Fenner Dunlop in the USA.

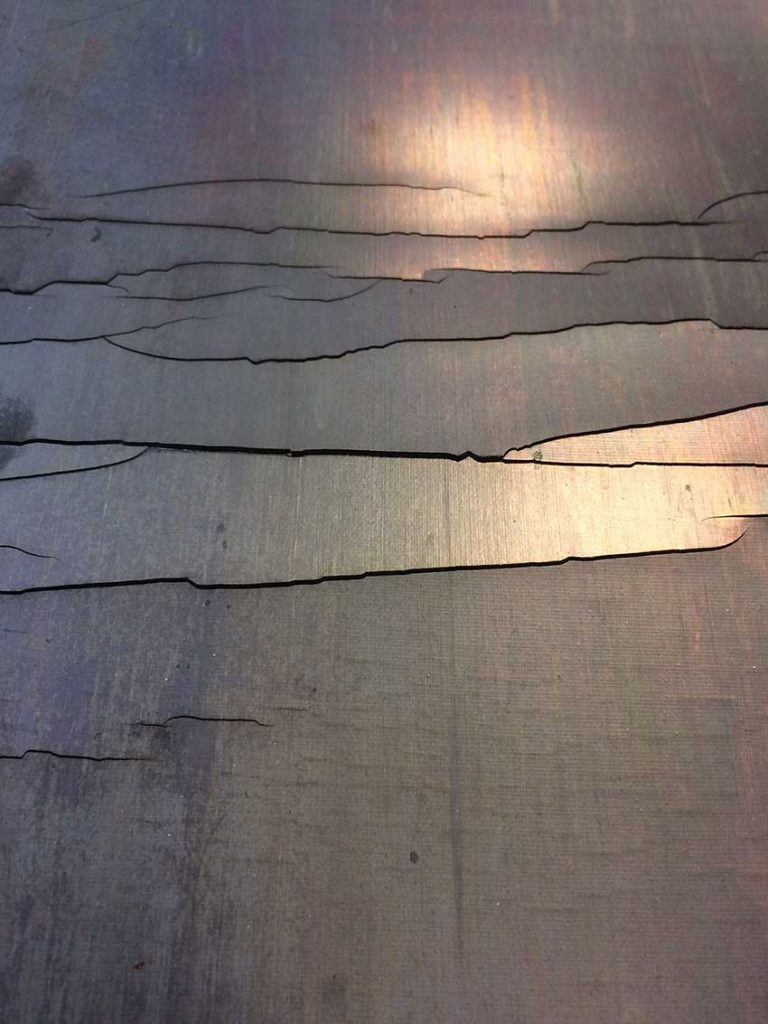

One of the most common reasons why belts claiming to be heat resistant need to be replaced prematurely is that the heat penetrates and builds up in the inner carcass of a multi-ply heat resistant belts causing the plies to separate, resulting in catastrophic failure. The term used to describe this phenomenon is ‘de-lamination’.

Delamination is a common cause of premature belt replacement

Making delamination a thing of the past

In order to minimise the chance of delamination, the Dunlop R & D team used a new, amazingly tough patented super strength mono-ply fabric that is exclusively produced in their own in-house weaving facilities in the USA. Although the key advantage of being a single-ply construction is that it is far less prone to delamination, the fabric also has a much greater resistance to ripping, tearing and impact compared to a conventional multi-ply carcass. Having such a tough carcass makes the belt far more durable, even in very tough conditions and therefore much more likely to provide a significantly longer operational life compared to its competitors.

Protecting the fabric carcass is a high heat resistant rubber compound, again developed and produced in-house, that has a long-established track record of being able to withstand maximum continuous material temperatures as high as 200°C and extreme peak temperatures as high as 400°C.

High temperatures create ‘accelerated ageing’ effects such as the hardening and cracking

In addition to its capabilities to resist the usual ‘accelerated ageing’ effects such as the hardening and cracking caused by exposure to extreme temperatures, the major advantages of the Optima Heat Xtreme rubber are its excellent physical properties including resistance to abrasive wear and superior adhesion strength.

Stronger in every way

Yet another big advantage of the Optima Heat Xtreme belt is the strength and reliability of the splice. The splice joint is the weakest part of any conveyor belt but this is even more the case with belts that are conveying high-heat materials where splice failures are an even more common cause of unplanned stoppages. If a belt is brought to a standstill while still loaded with hot materials then irreparable and extensive damage can occur. The use of cold vulcanizing materials is not recommended because a splice made in this way begins to lose strength from about 80°C onwards. High heat resistant rubber compounds usually have EP(D)M as a base polymer and the adhesion levels of EP(D)M and cold vulcanizing materials are poor. Hot vulcanisation is therefore the most reliable and effective method, with finger splicing rather than step splicing being the best option.

A finger splice joint retains up to 90% of tensile strength compared to 50% for a 2-ply step splice.

The much higher level of splice efficiency created by the use of a finger splice joint means that up to 90% of the belt’s tensile strength is retained compared to a 2-ply step splice, which only retains a maximum of 50% and a 3-ply step splice that only retains a maximum efficiency of 67%. Although the mono-ply belt is lighter, thinner and therefore well suited even for conveyor systems with relatively small pulleys and drums, the effect of using a finger splice is to create equivalent tensile strengths and belt safety factors that are more than comparable to much heavier and thicker 3 or 4-layer conventional belting.

Big opportunities

The market for heat resistant belting is exceptionally large in North America but the size of the market for this high performance heat resistant belting in Europe should not be under-estimated. There are some 170 cement plants and over 500 steel production plants located in Europe with more than 100 foundries in Sweden alone. Naturally, the bigger the market the more intense the competition. Chinese conveyor belt manufacturers in particular have targeted the market in their usual way by selling heat resistant belts that are extremely attractive in terms of price but at the expense of performance and longevity.

The market for heat resistant belt in Europe is considerable

Ironically, this effectively inspired Dunlop’s efforts in developing Optima Heat Xtreme. “We felt that the best way to combat cheap but unreliable belts was to develop a truly new heat resistant belt construction that could not only deliver in terms of its ability to resist extremely high temperatures over longer periods but also be super reliable in every other respect. Belts that last much longer cost less in the long run, that’s a fact”, explains Sales & Marketing Director Andries Smilda. “We already had fantastic rubber compounds that are proven to handle extreme temperatures over much longer periods than our competitors. But when you combine that kind of heat resistance with a super-strong mono-ply carcass that is much more resistant to impact, ripping and tearing and a much more resilient and reliable splice then it means that Optima Heat Xtreme is as close to being a ‘fit and forget’ heat resistant belt that you will ever find. We believe that it is a real ground-breaker”.

Made in the USA – for now

Although developed in collaboration with their colleagues in the USA, the physical development and initial production tests was almost entirely carried out in North America. As a logical consequence, Optima Heat Xtreme will initially be manufactured by Fenner Dunlop Americas operation based in Ohio but will only be available in Europe through Dunlop Conveyor Belting in The Netherlands. However, plans are already in place to start actual production in Drachten later this year.

The Dunlop objective, of course, is to attract new customers and win back some of ones that have perhaps been lured away by low prices and false promises. The management are clearly very excited about Optima Heat Xtreme. There can be no argument that, especially in recent years, the company have an extremely strong history in the successful development of conveyor belts that have extended the boundaries far beyond what was previously thought possible. Judging by their enthusiasm regarding Optima Heat Xtreme, they may well have done it again!

Autor: Bob Nelson