Cold Jet is increasingly facing the issue of responsible and sustainable growth of companies. The healthy ESG (Environmental, Social and Corporate Governance) business model requires adjusting the operating strategy, setting new goals, and specific actions that take into account ESG standards. These are key criteria that any company striving for responsible and sustainable development should pay attention to.

In terms of environmental protection, companies should consider energy consumption, waste management, emissions, and compliance with government environmental regulations. These things can be introduced at the design, production, and maintenance levels. This makes green cleaning methods increasingly important for industry. Traditional cleaning methods involve harmful secondary waste and the use of harsh chemicals that adversely affect both the environment and those involved in industrial cleaning. Among the many methods of industrial cleaning used in manufacturing plants, dry ice cleaning is one of the most environmentally friendly methods. This is a technology in which the cleaning medium is dry ice. Blown by a stream of compressed air, it strikes the surface, removing build-up. Upon contact with the substrate, the dry ice immediately sublimates, changing its state of aggregation from a solid to a gas.

Does dry ice cleaning contribute to CO2 emissions?

When undertaking environmentally friendly initiatives, it is worth answering the question of whether dry ice cleaning contributes to CO2 emissions. Dry ice is nothing more than solidified carbon dioxide, which comes from recovered CO2 in liquid form. Carbon dioxide is a naturally occurring gas in our atmosphere and is essential for life on Earth. Plants, for example, need carbon dioxide to perform photosynthesis to produce oxygen. It is also a key raw material in many major industries. Emissions from the commercial CO2 market (20-22 million tons/year) are negligible compared to total CO2 emissions (42 billion tons/year). Emissions from the commercial sector account for a mere 0.052% of global CO2 emissions. The use of dry ice does not add to your greenhouse gas (GhG) emissions/CO2e or carbon footprint calculation. The CO2 that forms dry ice was already accounted for when it was produced at the industrial or biogas facility and is considered as a recycled product.

How is dry ice produced?

Raw CO2 is captured from other industrial processes, such as bioethanol, biogas, or ammonia production. It is then compressed, purified, and stored, i.e. recycled for secondary use (CCU process – Carbon Capture and Utilization). From the storage tanks, the liquid carbon dioxide is directly piped to dry ice machines. Once the liquid CO2 is injected into the machines, the pressure is reduced to about 5 bar, which creates snow, which is compressed in a cylinder using a piston at a pressure of about 300 bar to produce granules, slices, or blocks of dry ice.

Dry ice is odorless, non-flammable, non-toxic, has an inert taste, and is non-abrasive. This makes it an environmentally sustainable solution for cleaning and transportation. In fact, dry ice often replaces harmful alternatives that increase the carbon footprint, such as cleaning with solvents and harsh chemicals. Dry ice used for cooling during the transport of food, pharmaceuticals, and biological samples replaces gel cartridges, which generate a lot of waste. The unique characteristics of dry ice make it a more cost-effective refrigerant and ensure maximum efficiency at the final stage of delivery to the recipient.

What are the benefits of using dry ice cleaning in implementing an internal sustainability policy?

Dry ice cleaning eliminates the negative externalities of commonly used sanitation, parts processing, and surface preparation processes. The use of dry ice reduces the excessive use of water in various processes, the negative effects of chemicals, and the additional waste from disposable cleaning products. We know how important it is to pay attention to the rising average cost of water, wastewater, and recycling. With a more limited supply and higher demand than ever before, it becomes necessary to consider how to reduce water consumption. In this case, it makes sense to use an industrial cleaning method that doesn’t use it at all. Dry ice cleaning meets this condition. Reducing environmental contamination is also important in the implementation of sustainability policies. Traditional cleaning methods require the use of disposable brushes, wipes, and rags, which end up in landfills. The use of dry ice reduces or even eliminates chemicals. Dry ice reduces greenhouse gas emissions by reducing the use of solvents. In addition, workers are not exposed to chemical cleaners and airborne particulates.

How does Cold Jet support corporate sustainability?

Cold Jet is offering industrial facilities a new generation of precision dry ice cleaning machines that allow companies to reduce their carbon footprint. The I3 MicroClean 2 is a technologically advanced and intelligent machine adapted to Industry 4.0. A number of innovative and patented solutions used in the new machine increase cleaning efficiency while reducing operating costs. Internal tests have shown an increase of more than 25% in the machine’s performance compared to its predecessor, allowing operators to clean faster and continuously from as low as 3 BAR.

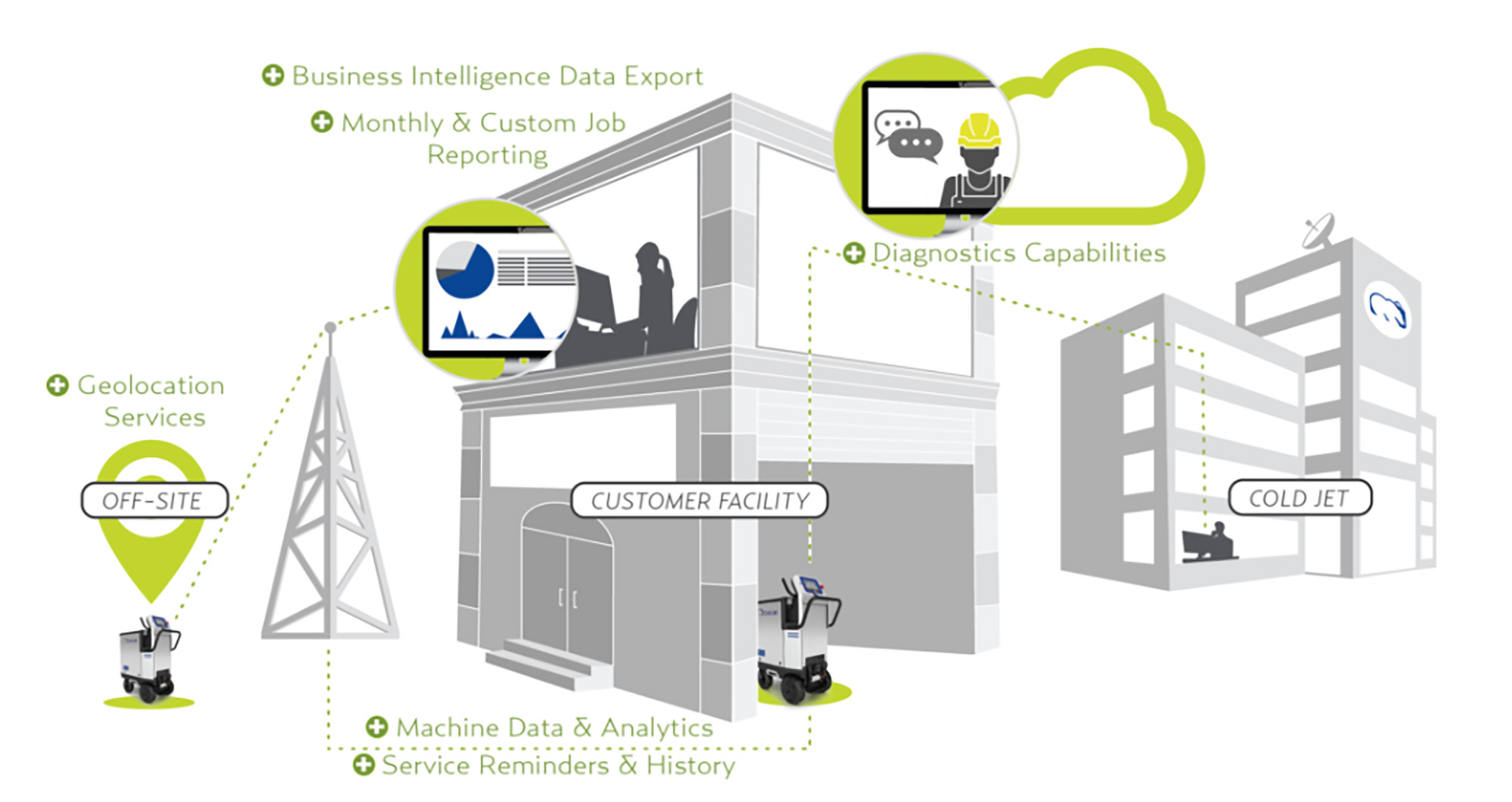

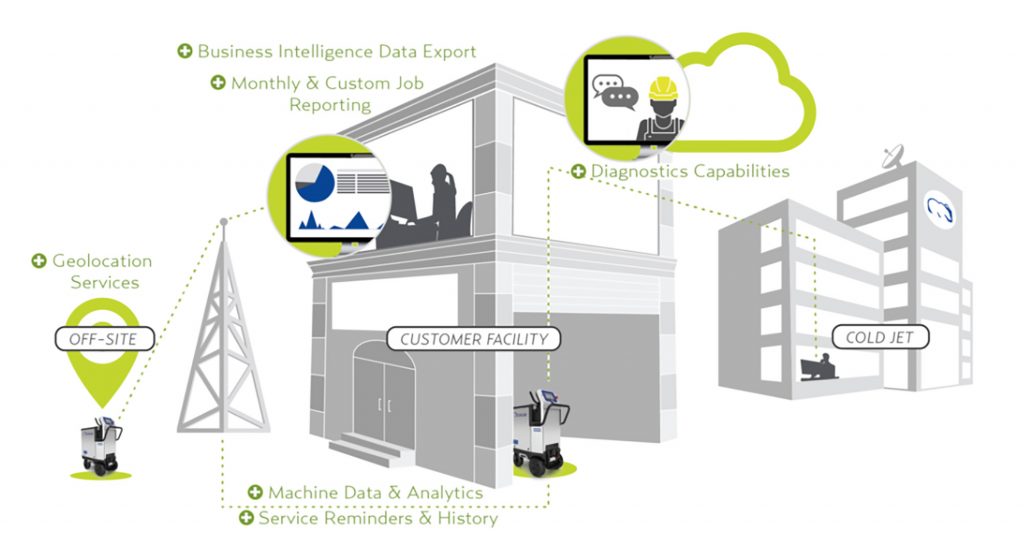

The I3 MicroClean 2 is equipped with a 7-inch LCD display with digital controls, allowing easy adjustment of cleaning process settings. This allows the user to save, the pressure and dry ice feed rate for future processes. The device is equipped with the Cold Jet CONNECT application, which can be used to collect data in the cloud and conduct analysis of statistics on the consumption of individual utilities. Cold Jet CONNECT is a customer service and technical support platform that made its premiere last year. It allows the user to have constant access to the parameters of the device, checking its technical condition, as well as its location.

Cold Jet CONNECT offers useful analysis to enable data-driven decision-making. Quick access is realized from any smartphone, tablet, or computer. The innovative solution offers remote technical support, virtual repairs with expert assistance, and machine performance analysis. The latest proposition guarantees remote monitoring, support, and data collection to improve operational performance, all with the aim of increasing the efficiency and profitability of the entire plant.

Cold Jet Commitment to Sustainability

From the beginning, Cold Jet is focused on developing environmentally sustainable solutions. Upon its founding, Cold Jet’s singular mission was to replace the use of toxic chemicals in aircraft coatings removal. In the proceeding years, the operational, environmental, and societal value of dry ice solutions became clear across all industries.

In addition to providing the global marketplace with sustainable solutions, Cold Jet is committed to improving environmental performance and to leaving a sustainable legacy for future generations. Cold Jet believes that this is a central part of being a responsible and successful company and will help to protect and enhance our global environment.

About Cold Jet

Cold Jet® has two distinct lines of business centered around the use of recycled CO2 as dry ice. The company provides environmental cleaning, surface preparation, and parts finishing systems to global manufacturing industries. These systems utilize particles of dry ice as a blasting medium. Secondly, they produce systems for the production, metering, and packaging of dry ice. These systems enable the consistent production of a controlled range of dry ice products for food transportation, cold chain management, and dry ice cleaning. Customers are using Golf Jet’s technology-based solutions to replace outdated processes that are inefficient and harmful to the environment and worker safety.

Cold Jet is headquartered in Loveland, Ohio, with international operations in Europe, Asia, Canada, and Mexico. For more information, visit www.coldjet.com.

Cold Jet Sp. z o.o.

Karolina Gruss-Kufel, Marketing Manager Eastern Europe

ul. Łukowska 12, 64-600 Oborniki, Poland

Phone: +48 506 179 323

E-mail: kgrusskufel@coldjet.com