GOSTOL-GOPAN d.o.o. Nova Gorica is a global provider of integrated industrial solutions for middle-sized and large industrial bakeries, including equipment for dough mixing, dividing, moulding, proofing, baking, and cooling.

Interview with Matjaž Furlan, Digitalization Software Developer at GOSTOL BAKERY SOLUTIONS.

Easy Engineering: What are the ranges of products and what types of services do you offer?

Matjaž Furlan: Concerning distinct types of dough, shapes and final products, as well as the specific methods of production in a specific geographic area, GOSTOL adjusts with specific solutions in dough processing and baking, which may comprise just individual parts of lines or an overall turn-key solution – from silos to packaging.

GOSTOL development and research follow client needs and demands on the market to deliver flexible and technologically innovative solutions that can improve the processes and reduce costs for bakeries.

E.E: Which are the most innovative products/services and what special features do they have?

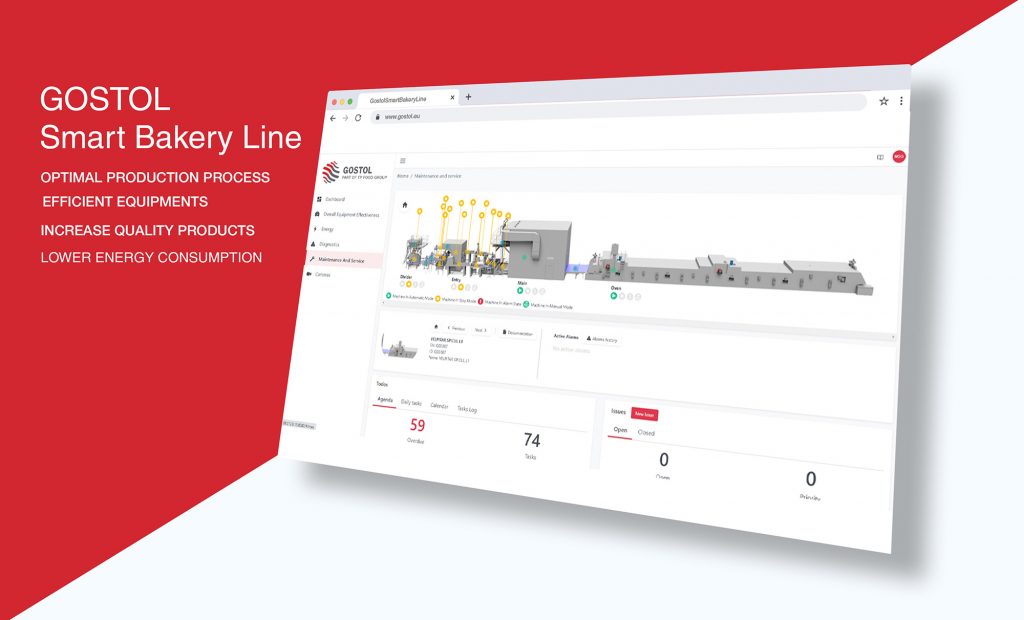

M.F: In August 2020, GOSTOL launched a bakery line digitization project and developed a web-based portal GOSTOL Smart Bakery Line app. GOSTOL Smart Bakery Line (GSBL) is a use of data collected on GOSTOL automated lines. A developed system captures several thousand of data from the bakery line (PLCs, sensors, cameras…) and stored them in the cloud.

GSBL analyzes the signals and displays them via a graphical interface to the user, who can check the current state, OEE production, and correct operation. GSBL provide notifications about errors and alarms and displays alerts and statistics. It shows deviations that allow for improvements in the control and construction of the lines.

In addition, GSBL can be linked to maintenance services and ordering spare parts. The user can use the system on a computer, tablet or phone, anywhere.

E.E: How important are these features for the users in their work?

M.F: GOSTOL Smart Bakery Line (GSBL) reduces downtime, service and maintenance costs, optimizes machine efficiency, improves processes and increases product quality.

Users can achieve greater overall equipment effectiveness (OEE). The OEE shows the metric value of product availability, performance and quality. Bakers need to see and understand where there are problems that disrupt production uptime.

By viewing actual run time and planned production time data, they can increase the uptime of the production line, keep it running at its best capacity, and reduce ejected pieces. The GSBL AI algorithm collects data from products and helps to get better results.

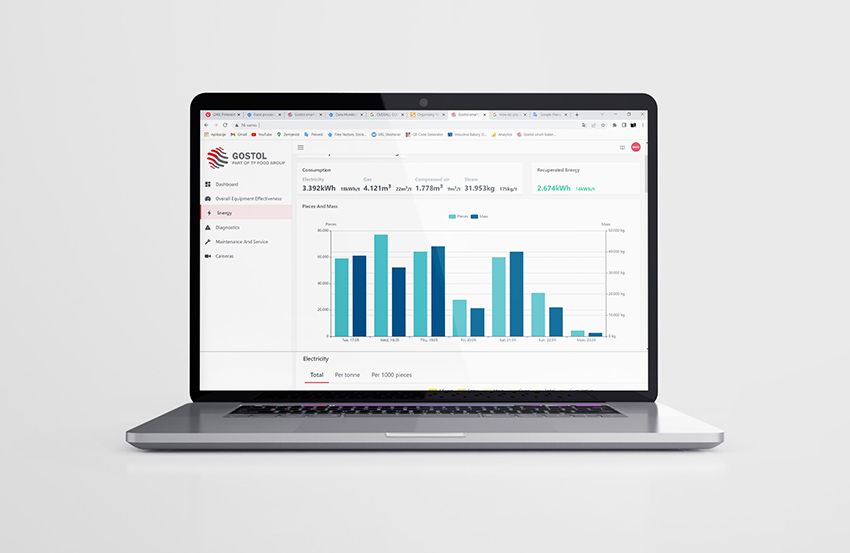

Bakeries are big energy consumers. Given the rise in energy prices, the efficient use of energy is essential in optimizing production costs. Therefore, data on energy consumption are very important. The GBSL system shows the consumption of electricity, gas and compressed air according to weight, recipe and number of pieces, thus enabling the user to rationalize energy consumption and not consequently lower costs.

E.E: How important is innovation in your field?

M.F: Modern equipment for food production and processing is becoming more and more technologically advanced. As mentioned before, bakery equipment manufacturers need to help bakers meet market challenges. The bakery market is becoming increasingly demanding. Customers want higher quality and more diverse types of products.

And here is the challenge for an innovative approach in the industry. Machine providers need to develop solutions that can satisfy maximum flexibility and agility.

New technologies are a tool for this, so-called mass customization.

Artificial intelligence, virtual reality, and all the processes known as Industry 4.0 can help manufacturers design machines that can facilitate and more accurately manage the baking process. On the other hand, they increase the possibility of acquiring flexible production to expand the range of products for their customers and grow their business.

E.E: How do your products/solutions impact cost-effectiveness for the users?

M.F: The first step in cost optimization is awareness of spending.

Users must have information about the effectiveness of the production process, the use of raw material and energy consumption, product results and machinery well working.

When based on data from digitized bakery line to set up the machinery adjusted at optimal settings, the result is a low waste of raw material, energy efficiency, improved processes and better product. The ultimate benefit is cost-saving.

By digitizing the entire production line or individual machines, the portal allows complete management and control of production processes and helps to plan periodic and professional service inspections.

All these features allow for avoiding high repair costs and consequent production downtime. We can extend the life of production equipment and its optimal operation throughout.

E.E: What kind of work do users who use these products/services do?

M.F: The GOSTOL Smart Bakery Line digital portal is a tool for the optimal management of production processes, which allows the user to set up a complete maintenance system.

It is an ideal resource for bakery managers, plant managers and food technologists.

Using GSBL, management can predict and monitor the production costs of baked goods.

Plant managers are aware of the status of a single machine or the entire plant. They get feedback on processes and equipment malfunctions. GSBL gives them the ability to understand where unexpected downtime is and where maintenance or replacement of spare parts is needed.

Food technologists can observe and verify the performance and quality of the product, the recipe and the consumption of the raw materials used in production. They can check the results of the baking processes and set the operation of the machines to obtain the ideal results on multiple recipes.

With new algorithms, vision cameras, and AI support GSBL portal helps recognize bad quality pieces on the middle and end of the line. So food technologists can change recipe parameters also during automation progress and reduce bad quality pieces.

E.E: How do your products increase profitability for users?

M.F: Overall Equipment Effectiveness (OEE) is a best practice to understand how well manufacturing operates. OEE is an effective metric for identifying losses, bench-marking progress, and improving the productivity of manufacturing equipment.

OEE is a value of how facilities, time and material are used compared to their full potential. Collecting data automatically from the machines is the best way for reliable OEE monitoring. GOSTOL automated bakery lines allow getting the necessary data about availability, performance and quality. Web-based portal Gostol Smart Bakery Line shows obtained data and provides them through an overall OEE report. These features give users a correct toolbox to set up machines to become more effective, lose waste and improve yields.

The final result is an improved production process, a consequently Higher Overall Equipment value and more profitability for users.

E.E: How do your products/services differ from other types on the market?

M.F: GSBL helps monitor the overall status on the line with simple graphic visuals and an intuitive user interface. The portal use charts and infographic to show daily report of complex data from the bakery plant.

Gostol Smart Bakery Line uses cloud service and is available on all types of devices. It also provides maximum security with AI integrated algorithms.

Gostol company can link GSBL with Bakery Business Intelligence and ERP systems.

With AI algorithms, the client has a list of machines that will need assistance. Predictive maintenance is one of the qualities of digitization and industry 4.0 that help reduce line downtime.

Another advantage of the application is that it provides users with a comprehensive insight into the energy consumed on the entire line or individual machine and for each part of the production. The energy consumption report includes data on the energy recovery offered by Gostol’s lines.

E.E: How do your products help solve users’ problems?

M.F: GOSTOL developed a web portal where our customers can see WHEN, WHY and WHAT recommended to control, maintain and modify to have an optimal production process. Through the GOSTOL Smart Bakery Line portal, it is possible to detect the consumption of raw materials and energy sources on any device.

The increasing price of energy sources gets more problematic for industrial bakeries. The energy consumption on production machines is a crucial point for bakeries not just because of saving costs but also concerning reducing the negative ecological impact.

GSBL gives a complete report of the energy consumption of each part of the line containing the data relating to the usage of electricity, gas, compressed air and steam. At the same time, it shows a complete view of the energy recovered by GOSTOL Lines. By seeing data of running processes, the Users can optimize and improve the settings of machines to reduce energy waste and costs.

Bakers want machines in the best condition and running 24/7. For this reason, maintenance is crucial. The diagnostic reports on GSBL contain a real-time display of alarms and warnings on the bakery line. At any time, customers can view the malfunctioning devices and take action if needed. They can check the machines’ run-time, the documentation, the assemblies and the instructions. GOSTOL connect the digitized line to maintenance service and provide efficiently and just in time maintenance. The service includes access to 24/7 remote support. Clients can also order parts directly from GOSTOL company.

E.E: What products/solutions are you going to launch in the future?

M.F: Gostol has developed the Gostol Smart bakery Line portal in collaboration with its customers and continues to improve the user experience through users feedback. According to the reviews, the prospect for further development will be centred on the instruction manual. The intent is to create a complete service virtual guide through VR glasses, which allows a 3D view of the parts and an online simultaneous guided support with the technicians. The main goal is to shorten the time and costs of maintenance services and avoid production downtime.

Another purpose is to develop the spare parts order service by creating an online shop connected directly to the portal to facilitate spare parts orders and speed up supply. These are the primary development intentions of the Gostol Smart bakery Line portal.

Linkedin https://www.linkedin.com/company/gostol-bakery-solutions/people/

Facebook https://www.facebook.com/gostolbakerysolutions